The Ultimate Guide To Toothbrush Tufting Machines

Are you interested in learning about the latest advancements in dental hygiene technology? Look no further than our comprehensive guide to toothbrush tufting machines. In this article, we will delve into the intricate details of these innovative tools and how they are revolutionizing the way toothbrushes are made. Whether you are a dental professional or simply someone who cares about their oral health, this ultimate guide is a must-read for anyone looking to stay informed on the cutting-edge of toothbrush manufacturing.

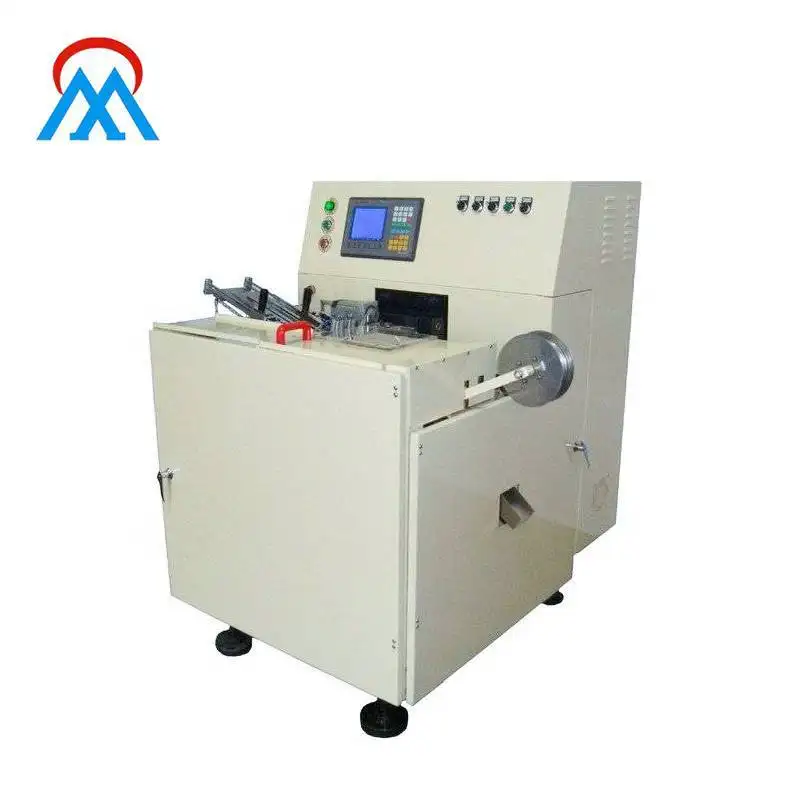

Types of Toothbrush Tufting Machines

Toothbrush tufting machines are a crucial component in the manufacturing process of toothbrushes. These machines are used to insert bristles, or tufts, into toothbrush heads, creating the final product that is used for oral hygiene. The process of tufting bristles may seem simple, but there are actually various types of toothbrush tufting machines that cater to different production needs and requirements.

One of the most common types of toothbrush tufting machines is the manual tufting machine. This type of machine requires an operator to manually insert bristles into the toothbrush head. Although this process can be time-consuming and labor-intensive, manual tufting machines are often used for small-scale production or for custom-made toothbrushes that require a high level of precision.

Another type of toothbrush tufting machine is the semi-automatic tufting machine. This machine combines manual labor with automation, as operators are required to load bristles into the machine, but the tufting process is automated. Semi-automatic tufting machines are suitable for medium-sized production runs, as they can increase efficiency and productivity while still allowing for some level of customization.

For larger-scale production, fully automatic tufting machines are the preferred choice. These machines are highly automated, requiring minimal human intervention for the tufting process. Fully automatic tufting machines are capable of producing a high volume of toothbrushes in a short amount of time, making them ideal for mass production.

There are also specialized toothbrush tufting machines designed for specific types of bristles or toothbrush designs. For example, there are machines that are specifically designed for inserting nylon bristles, as well as machines that can accommodate various bristle lengths and densities. Some machines are capable of creating different tufting patterns, such as crisscross or wave patterns, allowing for unique designs for toothbrushes.

In addition to the type of tufting machine, factors such as speed, accuracy, and maintenance requirements should also be considered when choosing a toothbrush tufting machine for a production facility. It is important to select a machine that can meet the production needs of the facility while also ensuring consistent quality and efficiency.

Overall, toothbrush tufting machines play a crucial role in the manufacturing process of toothbrushes. Whether it is a manual, semi-automatic, or fully automatic machine, each type offers its own set of advantages and cater to different production requirements. By understanding the different types of toothbrush tufting machines available, manufacturers can choose the right machine that suits their production needs and contributes to the overall quality of the final product.

How Toothbrush Tufting Machines Work

Toothbrush tufting machines are essential tools in the manufacturing process of toothbrushes. These machines are responsible for inserting bristles into the brush head, creating the familiar tooth cleaning tool that we use on a daily basis. Understanding how toothbrush tufting machines work is crucial for those in the dental hygiene industry or anyone interested in the production of oral care products.

The tufting process begins with the placement of pre-cut bristles into the tufting machine. These bristles are typically made of nylon or other synthetic materials that are durable and effective for cleaning teeth. The tufting machine then uses a series of mechanisms to securely attach these bristles to the brush head.

One of the key components of a toothbrush tufting machine is the gripper system. This system is responsible for grabbing individual bristles and positioning them in the correct pattern on the brush head. Precision is key in this process to ensure that the bristles are evenly distributed and securely held in place.

Once the bristles are in position, the tufting machine uses a clamping mechanism to hold them in place while they are attached to the brush head. This ensures that the bristles will not come loose during use, providing a reliable and effective toothbrush for consumers.

The tufting machine then uses a cutting mechanism to trim the bristles to the desired length. This ensures that the bristles are uniform in size and will provide a consistent cleaning experience for users. The cutting process is carefully calibrated to prevent damage to the bristles and ensure that they remain intact throughout the life of the toothbrush.

Overall, toothbrush tufting machines are highly specialized pieces of equipment that play a crucial role in the production of toothbrushes. Without these machines, the efficient and precise insertion of bristles into brush heads would be nearly impossible. Manufacturers rely on tufting machines to create high-quality toothbrushes that meet the standards of oral care professionals and consumers alike.

In conclusion, toothbrush tufting machines are complex and precise tools that are essential for the production of toothbrushes. Understanding how these machines work can provide valuable insight into the manufacturing process of oral care products. With advancements in technology and engineering, toothbrush tufting machines continue to evolve and improve, ensuring that consumers have access to high-quality and effective toothbrushes for their oral hygiene needs.

Factors to Consider When Choosing a Toothbrush Tufting Machine

When looking to invest in a toothbrush tufting machine, there are several important factors to consider to ensure that you are making the best decision for your business. From the type of bristles to the speed and efficiency of the machine, each aspect plays a crucial role in the overall performance and quality of the toothbrushes produced.

One of the first things to consider when choosing a toothbrush tufting machine is the type of bristles that will be used. There are various options available, such as nylon, polyester, and natural bristles, each with their own unique qualities and advantages. Nylon bristles are among the most popular choice for toothbrushes due to their durability and ability to effectively clean teeth. However, polyester bristles are also a popular option for their softness and flexibility, making them ideal for sensitive teeth. Natural bristles, on the other hand, are made from animal hair and are known for their gentle cleaning properties.

In addition to the type of bristles, it is important to consider the speed and efficiency of the toothbrush tufting machine. The speed at which the machine can produce toothbrushes plays a significant role in the overall productivity of your business. A higher speed machine may be more expensive, but it can greatly increase production output and efficiency. It is also important to consider the machine's ability to handle various toothbrush designs and sizes, as flexibility in production capabilities can be a valuable asset.

Another important factor to consider when choosing a toothbrush tufting machine is the level of automation and customization it offers. Some machines come equipped with advanced features such as automatic bristle trimming and sorting, which can greatly streamline the production process and improve overall quality control. Additionally, machines that offer a high level of customization allow for the production of unique and specialized toothbrush designs, catering to specific market demands and preferences.

When investing in a toothbrush tufting machine, it is also important to consider the level of maintenance and support provided by the manufacturer. Regular maintenance and servicing are crucial in ensuring the longevity and efficiency of the machine, so it is important to choose a manufacturer that offers comprehensive support and assistance. Additionally, it is important to consider the availability of replacement parts and technical support to minimize downtime and production delays.

In conclusion, choosing the right toothbrush tufting machine is a crucial decision that can greatly impact the success of your business. By considering factors such as bristle type, speed and efficiency, automation and customization, and maintenance and support, you can ensure that you are making the best possible investment for your production needs. With the right machine in place, you can effectively meet the demands of the market and produce high-quality toothbrushes that meet and exceed consumer expectations.

Maintenance and Troubleshooting Tips for Toothbrush Tufting Machines

Toothbrush tufting machines are essential equipment in the manufacturing of toothbrushes, playing a crucial role in the production process. These machines are responsible for tufting the bristles onto the toothbrush head, ensuring the final product is of high quality and meets industry standards. However, like any piece of machinery, toothbrush tufting machines require regular maintenance and troubleshooting to ensure they function efficiently and effectively.

Maintenance of toothbrush tufting machines is vital to prevent breakdowns and ensure optimal performance. Regular cleaning of the machine is essential to remove any built-up debris or dust that may affect its operation. This includes cleaning the tufting heads, feed systems, and any other components that come into contact with the bristles. Additionally, lubricating moving parts and replacing worn-out components are necessary to prevent wear and tear and prolong the machine's lifespan.

Regular inspections should also be conducted to identify any potential issues before they escalate into more significant problems. Checking for loose or damaged parts, irregularities in the tufting process, and unusual noises can help prevent costly repairs and downtime. It is recommended to create a maintenance schedule and adhere to it to ensure the machine operates smoothly and efficiently.

In addition to regular maintenance, troubleshooting tips are essential for addressing any unexpected issues that may arise during the operation of toothbrush tufting machines. One common issue is bristle breakage, which can be caused by various factors such as improper tension settings, worn-out components, or defective materials. Adjusting the tension settings, replacing worn-out parts, and using high-quality materials can help prevent bristle breakage and improve the tufting process.

Another common issue is tufting head jams, which can occur due to debris build-up, improper alignment, or mechanical issues. Clearing any debris, adjusting the alignment, and inspecting the tufting heads for damage can help resolve tufting head jams and prevent production delays. It is essential to address these issues promptly to minimize downtime and ensure the smooth operation of the machine.

Overall, proper maintenance and troubleshooting of toothbrush tufting machines are essential for ensuring the efficiency and effectiveness of the production process. By following these tips and guidelines, manufacturers can improve the lifespan of their machines, reduce downtime, and produce high-quality toothbrushes that meet industry standards. Investing time and effort in maintaining and troubleshooting toothbrush tufting machines will ultimately lead to improved productivity and profitability in the long run.

Innovations in Toothbrush Tufting Machine Technology

The world of toothbrush tufting machines is constantly evolving with new innovations and technologies being introduced to improve efficiency, quality, and overall performance. In this ultimate guide to toothbrush tufting machines, we will delve into the latest advancements in this field and explore how these innovations are shaping the future of toothbrush manufacturing.

One of the key innovations in toothbrush tufting machine technology is the integration of robotic automation. Robotic arms are now being used to precisely position and secure the bristles onto the toothbrush head, resulting in a more uniform and consistent tufting pattern. This not only improves the overall quality of the toothbrush but also helps to reduce production time and costs.

Another important innovation in toothbrush tufting machine technology is the development of high-speed tufting machines. These machines are capable of tufting bristles at a much faster rate than traditional machines, allowing manufacturers to significantly increase their production output. This is particularly beneficial for companies that have high demand for toothbrushes and need to meet tight deadlines.

Furthermore, advancements in material technology have also had a significant impact on toothbrush tufting machine technology. The development of new, more durable materials for toothbrush bristles has made it possible to create toothbrushes that are not only more effective at cleaning teeth but also more long-lasting. Tufting machines are now able to easily work with these new materials, ensuring that toothbrushes are of the highest quality.

In addition to these technological advancements, innovations in design software have also played a crucial role in shaping the future of toothbrush tufting machines. With the use of advanced CAD software, manufacturers are able to create intricate designs for toothbrush heads and bristle patterns, allowing for more customizable and unique toothbrushes to be produced. This level of customization not only allows for greater creativity in toothbrush design but also helps to meet the specific needs and preferences of consumers.

Overall, the advancements in toothbrush tufting machine technology have revolutionized the way toothbrushes are manufactured and have paved the way for a new era of toothbrush design and production. With the integration of robotic automation, high-speed tufting machines, new materials, and design software, manufacturers are now able to create toothbrushes that are not only more efficient and effective at cleaning teeth but also more personalized and innovative. As technology continues to advance, the possibilities for toothbrush tufting machines are endless, and the future of toothbrush manufacturing looks brighter than ever.

Conclusion

In conclusion, toothbrush tufting machines are essential tools in the toothbrush manufacturing industry, allowing for precision and efficiency in creating top-quality toothbrushes. From understanding the various types of tufting machines to selecting the right one for your production needs, this ultimate guide has provided valuable insights and information to help you make informed decisions. By investing in a high-quality tufting machine, you can streamline your manufacturing process, improve product quality, and ultimately, satisfy your customers. So, whether you are an experienced toothbrush manufacturer or a newcomer to the industry, utilizing the knowledge gained from this guide will undoubtedly contribute to the success of your toothbrush manufacturing venture.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019