The Evolution Of Toothbrush Tufting Machines: Innovations In Oral Care Technology

In the ever-evolving world of oral care technology, toothbrush tufting machines have undergone revolutionary advancements, leading to improved dental hygiene and overall oral health. From the traditional tufting methods to the most cutting-edge innovations, these machines play a crucial role in creating the brushes we use every day. Explore the fascinating evolution of toothbrush tufting machines and discover how these advancements are shaping the future of oral care.

- The History of Toothbrush Tufting Machines

The history of toothbrush tufting machines is a fascinating journey that highlights the continuous innovations in oral care technology. From the early days of manual toothbrush production to the highly advanced automated machines used today, the evolution of toothbrush tufting machines has revolutionized the way we care for our teeth.

In the early 20th century, toothbrushes were primarily made by hand, with bristles being individually inserted into the brush head. This labor-intensive process limited the production capacity and quality consistency of toothbrushes. However, in the 1940s, the first toothbrush tufting machines were developed, which greatly improved the efficiency and precision of toothbrush production.

These early tufting machines were relatively simple, using a rotating drum to insert bristles into pre-drilled holes in the brush head. Over the years, advancements in technology have led to the development of more sophisticated toothbrush tufting machines. Today, these machines are equipped with high-speed, precision tufting heads that can insert thousands of bristles per minute with unparalleled accuracy.

One of the key innovations in toothbrush tufting machines is the use of automated robotic systems. These systems can handle the entire tufting process, from bristle selection to final assembly, with minimal human intervention. This automation has greatly increased the production capacity of toothbrush manufacturers and has led to a significant reduction in costs.

Furthermore, advancements in materials science have also played a crucial role in the evolution of toothbrush tufting machines. The development of new, more durable bristle materials has allowed for the creation of toothbrushes that are more effective at cleaning teeth and gums. Additionally, the integration of antimicrobial properties in bristles has helped to improve oral hygiene and prevent the growth of bacteria on toothbrushes.

In recent years, there has been a growing focus on sustainability in the oral care industry. Toothbrush tufting machines are now being designed to minimize waste and optimize energy efficiency. Manufacturers are also exploring the use of biodegradable materials in toothbrush production to reduce environmental impact.

Overall, the history of toothbrush tufting machines is a testament to the continuous innovation and dedication of the oral care industry to improve the quality and effectiveness of toothbrushes. As technology continues to evolve, we can expect to see even more groundbreaking advancements in toothbrush tufting machines that will further enhance our oral health and well-being.

- Advancements in Automated Tufting Technology

In the ever-evolving world of oral care technology, toothbrush tufting machines have seen significant advancements in recent years. With a focus on the automation of tufting processes, manufacturers are constantly striving to improve the efficiency and effectiveness of these machines.

One of the most notable advancements in toothbrush tufting machines is the integration of automated technology. Gone are the days of manual tufting, where workers painstakingly inserted each individual bristle into the toothbrush head. Now, automated machines are able to tuft hundreds of bristles in a fraction of the time, significantly increasing production efficiency.

The use of robotics and computerized systems has revolutionized the tufting process, allowing for greater precision and consistency in bristle placement. These advancements not only ensure a more uniform and effective toothbrush, but also reduce the margin for error that can occur with manual tufting.

Furthermore, automated tufting machines are equipped with sensors and monitoring systems that can detect any issues or irregularities during the tufting process. This real-time feedback allows operators to quickly address any issues and make necessary adjustments, ensuring a high-quality end product.

In addition to automation, innovations in toothbrush tufting machines have also focused on the materials and design of the bristles themselves. Manufacturers are constantly experimenting with new materials that offer improved cleaning efficiency and durability. From nylon to silicone bristles, there is a wide range of options available to cater to different oral care needs.

Furthermore, the design of the bristles has also evolved to better accommodate the varying shapes and sizes of toothbrush heads. Some machines are now capable of tufting angled bristles or custom patterns, ensuring a more effective clean for users.

Overall, the evolution of toothbrush tufting machines has been driven by a commitment to improving oral care technology. By embracing automation and incorporating new materials and designs, manufacturers are able to produce toothbrushes that are more effective, efficient, and tailored to individual needs.

As advancements in automated tufting technology continue to progress, we can expect to see even greater innovations in the field of oral care. From improved cleaning capabilities to personalized toothbrush designs, the future of toothbrush tufting machines is bright and promising.

- Impact of Innovation on Oral Care Industry

The oral care industry has seen a significant evolution in recent years, thanks to the impact of innovation on toothbrush tufting machines. These machines play a crucial role in the manufacturing process of toothbrushes, making them an essential component of the oral care industry. This article will explore the evolution of toothbrush tufting machines and how they have revolutionized oral care technology.

Toothbrush tufting machines are responsible for creating the bristles on toothbrushes, which are crucial for effectively cleaning teeth and gums. In the past, these machines were manual and required a skilled operator to carefully place each bristle on the toothbrush head. However, with advancements in technology, automated toothbrush tufting machines have emerged, streamlining the manufacturing process and increasing efficiency.

One of the key innovations in toothbrush tufting machines is the use of robotic technology. Robotic tufting machines are able to precisely place bristles on toothbrush heads with incredible accuracy, ensuring a consistent and high-quality end product. This has drastically reduced the margin for error and increased the speed of production, allowing manufacturers to meet the growing demand for toothbrushes in a timely manner.

Another innovation in toothbrush tufting machines is the development of interchangeable tufting heads. These heads allow manufacturers to easily switch between different bristle types, sizes, and configurations, enabling them to create a wide range of toothbrushes to meet the diverse needs of consumers. This flexibility has been instrumental in the customization of toothbrushes, catering to specific oral care needs such as sensitive teeth or gum health.

Furthermore, the integration of artificial intelligence (AI) technology in toothbrush tufting machines has further enhanced their performance. AI algorithms analyze data in real-time to optimize the tufting process, identifying patterns and making adjustments to ensure optimal bristle placement. This level of precision has not only improved the quality of toothbrushes but has also reduced waste and increased overall efficiency in manufacturing.

Overall, the evolution of toothbrush tufting machines has had a profound impact on the oral care industry. These innovations have revolutionized the manufacturing process, making it more efficient, accurate, and customizable. As a result, consumers can now enjoy a wide range of toothbrush options that cater to their specific oral care needs, ultimately promoting better oral health outcomes. The future of oral care technology looks promising, with continued advancements in toothbrush tufting machines leading the way.

- Improvements in Tufting Machine Efficiency

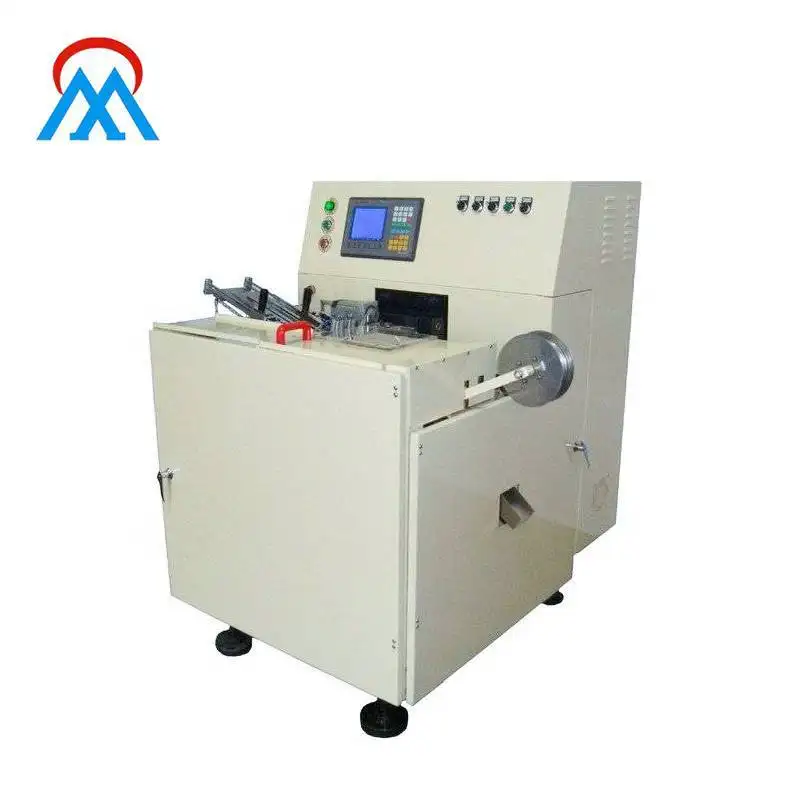

Toothbrush tufting machines have undergone significant advancements in recent years, leading to improvements in efficiency and overall performance. These machines play a crucial role in the production of toothbrushes, as they are responsible for inserting bristles into the brush head. The evolution of toothbrush tufting machines has revolutionized the oral care industry, making it easier for manufacturers to produce high-quality toothbrushes at a faster pace.

One of the key improvements in tufting machine efficiency is the development of automated systems that streamline the tufting process. These machines are equipped with advanced technology that allows them to precisely insert bristles into the brush head with minimal human intervention. This not only reduces the margin of error but also speeds up production time, resulting in higher output and lower production costs.

In addition to automation, advancements in tufting machine design have also contributed to improved efficiency. Modern tufting machines are more compact and versatile, allowing for greater flexibility in production. Manufacturers can easily switch between different brush designs and bristle configurations, making it easier to meet the diverse needs of consumers. The machines are also equipped with improved bristle feeding systems, ensuring a steady supply of bristles and minimizing downtime.

Furthermore, advancements in tufting technology have led to the development of machines that can accommodate a wider range of bristle materials. Traditionally, toothbrush bristles were made from nylon, but with the rise of eco-friendly and sustainable materials, manufacturers are now using alternatives such as bamboo and biodegradable plastics. Modern tufting machines are capable of handling these new materials, allowing for more environmentally friendly toothbrush options to enter the market.

The evolution of toothbrush tufting machines has not only improved efficiency but also quality. The precision and accuracy of modern tufting machines result in toothbrushes that are more durable and effective in cleaning teeth. Bristles are inserted evenly and securely, ensuring that they do not fall out or become misaligned during use. This not only enhances the overall user experience but also prolongs the lifespan of the toothbrush, reducing waste and promoting sustainability.

Overall, the innovations in toothbrush tufting machine technology have had a significant impact on the oral care industry. Manufacturers are now able to produce high-quality toothbrushes more efficiently and sustainably, meeting the growing demand for oral hygiene products. As technology continues to advance, we can expect further improvements in tufting machine efficiency, leading to even better oral care solutions for consumers worldwide.

- Future Trends in Toothbrush Tufting Technology

In recent years, there have been significant advancements in the field of toothbrush tufting technology, paving the way for future trends in oral care innovation. Toothbrush tufting machines play a crucial role in the production of high-quality toothbrushes, ensuring that the bristles are securely and evenly attached to the brush head. These machines have evolved over time, incorporating cutting-edge technologies to improve efficiency, precision, and overall performance.

One of the key trends in toothbrush tufting technology is the use of robotics and automation. Manufacturers are increasingly turning to robotic systems to streamline the tufting process, reducing human error and increasing productivity. Robotic tufting machines are capable of handling a wide range of bristle materials and configurations, allowing for greater customization and flexibility in toothbrush design. These advanced systems also offer higher levels of accuracy and consistency, resulting in superior product quality.

Another emerging trend in toothbrush tufting technology is the integration of artificial intelligence (AI) and machine learning algorithms. By harnessing the power of AI, manufacturers can optimize the tufting process in real-time, adjusting parameters such as bristle density, length, and orientation to meet specific requirements. Machine learning algorithms can analyze data from previous tufting runs to identify patterns and trends, enabling continuous improvement and fine-tuning of the production process.

Furthermore, advancements in materials science have led to the development of innovative bristle materials that offer superior cleaning performance and durability. Manufacturers are experimenting with alternative materials such as silicone and antibacterial fibers, which can provide enhanced plaque removal and reduce the risk of bacterial growth. These new materials are also more environmentally friendly, as they can be recycled or biodegraded at the end of their lifespan.

Additionally, sustainability is a growing concern in the oral care industry, prompting manufacturers to adopt eco-friendly practices in their production processes. Some toothbrush tufting machines now incorporate energy-saving features and use environmentally friendly materials, helping to reduce the carbon footprint of toothbrush production. Sustainable packaging options, such as biodegradable or compostable materials, are also being explored to minimize environmental impact.

Overall, the evolution of toothbrush tufting machines is driving unprecedented levels of innovation in oral care technology. With advancements in robotics, AI, materials science, and sustainability, manufacturers are poised to deliver cutting-edge toothbrushes that offer superior cleaning performance, durability, and environmental responsibility. As these trends continue to shape the future of oral care, consumers can look forward to a new era of toothbrush technology that prioritizes both effectiveness and sustainability.

Conclusion

In conclusion, the evolution of toothbrush tufting machines has revolutionized the oral care industry, paving the way for advancements in technology and improved dental hygiene practices. From the early manual tufting process to the sophisticated automated machines of today, manufacturers have continually strived to enhance the quality and effectiveness of toothbrushes, ultimately benefiting consumers worldwide. As we look towards the future, it is exciting to think about the potential innovations that will continue to shape the landscape of oral care technology, ultimately leading to better oral health outcomes for individuals of all ages. With continued research and development, we can expect to see even more cutting-edge advancements that will further improve the way we care for our teeth and gums. Let us embrace these advancements and look forward to a future where oral care technology continues to evolve and enhance our overall well-being.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019