Revolutionizing Oral Hygiene: The Toothbrush Tufting Machine

Are you tired of spending countless hours manually tufting toothbrushes? Say goodbye to the hassle and revolutionize your oral hygiene routine with the innovative Toothbrush Tufting Machine. This groundbreaking technology is changing the game in oral hygiene manufacturing, making the process faster, more efficient, and ensuring high-quality results every time. Discover how this revolutionary machine is transforming the industry and why it’s a must-have for anyone serious about oral health.

- The History of Toothbrush Tufting

The History of Toothbrush Tufting

Toothbrushes have been around for centuries, with evidence of their use dating back to ancient civilizations such as the Babylonians and the Egyptians. However, it wasn't until the late 18th century that the toothbrush as we know it today began to take shape. With the invention of the toothbrush tufting machine, oral hygiene was revolutionized, making toothbrushes more efficient, accessible, and affordable than ever before.

The toothbrush tufting machine, also known as a toothbrush bristle machine, is a device used to insert bristles into the head of a toothbrush. Before the invention of this machine, toothbrushes were typically made by hand, with bristles being individually inserted into holes in the brush head. This process was labor-intensive and time-consuming, limiting the availability and affordability of toothbrushes for most people.

The development of the toothbrush tufting machine changed all of that. Invented in the early 20th century, this machine automated the process of inserting bristles into toothbrush heads, greatly increasing production efficiency and lowering costs. This allowed toothbrushes to be mass-produced on a large scale, making them more readily available to the general public.

One of the key innovations of the toothbrush tufting machine was the ability to create toothbrushes with different bristle patterns and densities. By adjusting the settings on the machine, manufacturers could vary the length, thickness, and arrangement of bristles to create toothbrushes tailored to specific oral hygiene needs. This customization allowed for the development of toothbrushes designed for sensitive teeth, braces, or specific cleaning requirements.

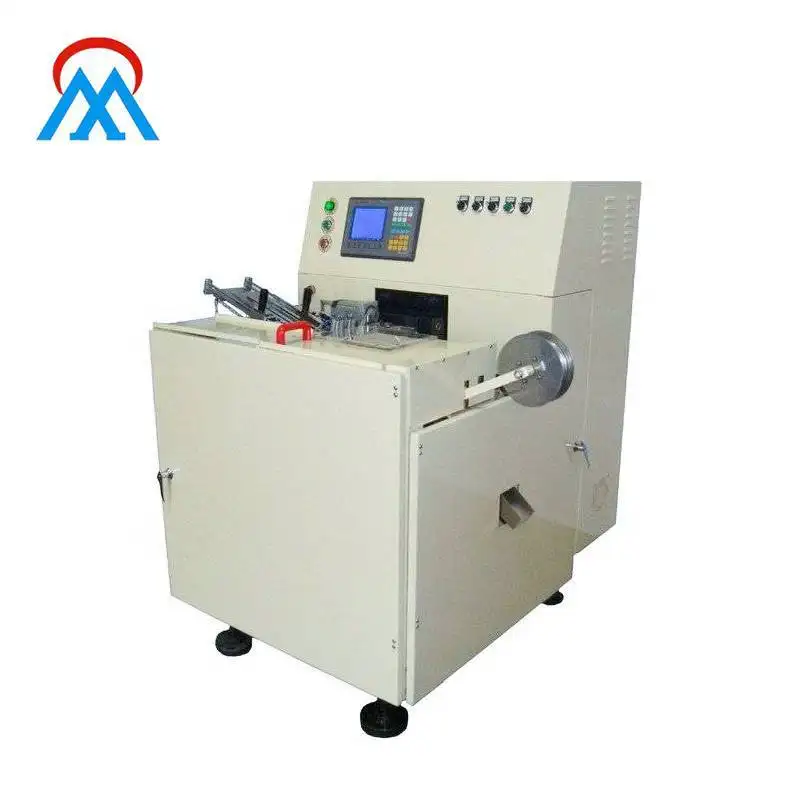

Over the years, advancements in technology have further improved the toothbrush tufting machine. Modern machines are equipped with computerized controls, allowing for precise programming and adjustment of bristle placement. This level of precision ensures that each toothbrush produced is consistent in quality and performance.

Today, toothbrush tufting machines are used by toothbrush manufacturers around the world to produce millions of toothbrushes each year. These machines have made oral hygiene more accessible than ever, allowing people of all ages and income levels to have access to an essential tool for maintaining dental health.

In conclusion, the toothbrush tufting machine has played a crucial role in the evolution of oral hygiene. By automating the production of toothbrushes and allowing for customization of bristle patterns, these machines have made toothbrushes more efficient, accessible, and effective than ever before. Thanks to the invention of the toothbrush tufting machine, maintaining good oral hygiene has never been easier.

- How the Machine Works

Revolutionizing Oral Hygiene: The Toothbrush Tufting Machine - How the Machine Works

In today's fast-paced world, technology is constantly evolving and improving the way we live our lives. One such innovation that has revolutionized oral hygiene is the toothbrush tufting machine. This groundbreaking piece of equipment plays a crucial role in the production of toothbrushes, ensuring that they are made efficiently and effectively. In this article, we will delve into how the toothbrush tufting machine works and explore the intricate processes involved in its operation.

To understand how the toothbrush tufting machine works, we first need to grasp the basics of toothbrush manufacturing. A toothbrush is typically made up of three main components: the handle, the bristles, and the tufting. The tufting refers to the process of attaching the bristles to the brush head, creating the familiar brush shape that we use to clean our teeth. This is where the toothbrush tufting machine comes into play.

The toothbrush tufting machine is a specialized piece of equipment that automates the process of attaching bristles to the brush head. This machine consists of several key components, including a feeder system for the bristles, a tufting head, and a control system. The feeder system is responsible for supplying the bristles to the tufting head, where they are arranged and secured in place. The control system oversees the entire operation, ensuring that the bristles are tufted accurately and efficiently.

The process begins with the feeder system loading the bristles onto the tufting head, where they are arranged in the desired pattern. The tufting head then moves across the brush head, securing the bristles in place using a combination of heat and pressure. This ensures that the bristles are firmly attached and will not come loose during use. The control system monitors every step of the process, adjusting the settings as needed to maintain precision and consistency.

One of the key advantages of the toothbrush tufting machine is its speed and efficiency. With the ability to tuft hundreds of brushes per minute, this machine significantly increases production output and reduces manufacturing costs. Additionally, the automated nature of the process ensures that each brush is tufted with the same level of quality and precision, leading to a more consistent product for consumers.

Furthermore, the toothbrush tufting machine allows for increased customization and innovation in toothbrush design. Manufacturers can experiment with different bristle patterns, colors, and materials, creating unique and specialized brushes for various purposes. This level of flexibility would not be possible without the advanced capabilities of the tufting machine.

In conclusion, the toothbrush tufting machine is a game-changer in the world of oral hygiene. By streamlining the tufting process and increasing production efficiency, this machine has transformed the way toothbrushes are manufactured. With its speed, precision, and versatility, the tufting machine is paving the way for new advancements in oral care. Next time you brush your teeth, take a moment to appreciate the technology behind your trusty toothbrush and the intricate workings of the toothbrush tufting machine.

- Advantages of Automated Tufting

In today's fast-paced world, advancements in technology have revolutionized every aspect of our lives, including our oral hygiene. One such innovative technology that is making waves in the dental industry is the toothbrush tufting machine. This cutting-edge machine automates the process of creating toothbrush bristles, providing numerous advantages over traditional methods of tufting.

One of the primary advantages of using an automated tufting machine is the consistency and precision it offers. Traditional tufting methods often rely on manual labor, which can result in variations in bristle length and density. With a toothbrush tufting machine, these inconsistencies are eliminated as the machine can produce uniform and perfectly aligned bristles every time. This ensures that each toothbrush is of the highest quality and provides an effective cleaning experience for the user.

Furthermore, automated tufting machines are incredibly efficient and can produce a large number of toothbrushes in a short amount of time. This increased production capacity allows dental manufacturers to meet growing demands for oral hygiene products and ensures a steady supply of toothbrushes to consumers worldwide. Additionally, the streamlined production process reduces labor costs and maximizes efficiency, ultimately leading to cost savings for both manufacturers and consumers.

Apart from efficiency and consistency, toothbrush tufting machines also offer improved hygiene benefits. Traditional tufting methods often involve manual handling of bristles, which can introduce contaminants and bacteria into the toothbrush manufacturing process. Automated tufting machines minimize human contact with the bristles, creating a more sterile production environment and reducing the risk of cross-contamination. This results in safer and more hygienic toothbrushes that promote better oral health for users.

Another advantage of automated tufting machines is their versatility and customization options. Manufacturers can easily adjust the settings of the machine to create toothbrushes with different bristle lengths, colors, and densities to cater to a wide range of consumer preferences. This flexibility allows dental manufacturers to offer a diverse range of toothbrush options to meet the evolving needs of consumers in the market.

In conclusion, the toothbrush tufting machine is truly revolutionizing oral hygiene by offering numerous advantages over traditional tufting methods. From improved consistency and efficiency to enhanced hygiene and customization options, automated tufting machines are setting a new standard in toothbrush manufacturing. As technology continues to advance, it is clear that automated tufting machines will play a crucial role in shaping the future of oral hygiene products and ensuring a cleaner and healthier smile for consumers worldwide.

- Impact on Oral Health Industry

The invention of the toothbrush tufting machine has completely revolutionized the oral health industry, bringing about unprecedented advancements in the manufacturing of toothbrushes. This innovative machine has had a significant impact on the way toothbrushes are produced, resulting in higher quality products that are more efficient, cost-effective, and environmentally friendly.

Before the toothbrush tufting machine was introduced, toothbrushes were typically assembled by hand, a time-consuming and labor-intensive process. This manual labor often resulted in inconsistencies in the quality of the final product, leading to variations in the bristle density and alignment. However, with the introduction of the tufting machine, manufacturers were able to automate the process of attaching bristles to the toothbrush handle, ensuring uniformity and precision in every toothbrush produced.

One of the key advantages of the toothbrush tufting machine is its ability to significantly increase production efficiency. By automating the bristle attachment process, manufacturers are able to produce a greater number of toothbrushes in a shorter amount of time, meeting the growing demand for oral hygiene products in a more timely manner. This increased efficiency not only benefits manufacturers by reducing production costs, but it also allows consumers to have access to high-quality toothbrushes at a more affordable price.

Furthermore, the toothbrush tufting machine has also played a crucial role in improving the overall quality of toothbrushes. With the ability to precisely control the placement of bristles on the toothbrush handle, manufacturers can ensure that each toothbrush meets the highest standards of quality and durability. This has led to a significant improvement in the effectiveness of toothbrushes in cleaning teeth and promoting good oral hygiene, ultimately benefiting consumers in their oral health maintenance.

In addition to its impact on production efficiency and product quality, the toothbrush tufting machine has also had a positive environmental impact. By streamlining the manufacturing process, manufacturers are able to reduce the amount of waste generated during production, leading to a more sustainable and eco-friendly manufacturing process. This has helped to reduce the environmental footprint of the oral health industry, making a positive contribution to environmental conservation efforts.

Overall, the toothbrush tufting machine has truly revolutionized the oral health industry, transforming the way toothbrushes are manufactured and improving the quality, efficiency, and sustainability of oral hygiene products. With its ability to increase production efficiency, enhance product quality, and reduce environmental impact, the toothbrush tufting machine has set a new standard for toothbrush manufacturing, paving the way for a brighter and healthier future for oral hygiene.

- Future Developments in Toothbrush Technology

In the rapidly evolving world of oral hygiene, advancements in toothbrush technology are continuously being made to ensure better oral health for individuals. One such innovation that is revolutionizing the way toothbrushes are manufactured is the toothbrush tufting machine. This groundbreaking technology is set to reshape the toothbrush industry, offering improved efficiency, precision, and overall quality in toothbrush production.

The toothbrush tufting machine is a marvel of modern engineering, designed to automate the process of attaching bristles to toothbrush heads. Traditionally, this process was done manually, requiring skilled workers to painstakingly insert each individual bristle into the toothbrush head. However, with the introduction of the toothbrush tufting machine, this labor-intensive task has been streamlined, allowing for faster production and higher levels of consistency in bristle placement.

One of the key features of the toothbrush tufting machine is its ability to precisely control the length and density of bristles on each toothbrush head. This level of customization ensures that toothbrushes are tailored to meet the specific needs and preferences of individual consumers. Whether someone prefers a softer or firmer bristle texture, the toothbrush tufting machine can easily accommodate these variations, providing a personalized brushing experience for all.

Furthermore, the toothbrush tufting machine is equipped with advanced technology that allows for seamless integration with other manufacturing processes. This means that toothbrushes can be produced more efficiently, with reduced waste and a faster time to market. By automating the tufting process, manufacturers can increase their production capacity and meet the growing demand for high-quality toothbrushes worldwide.

In addition to improving production efficiency, the toothbrush tufting machine also plays a crucial role in enhancing the overall quality of toothbrushes. By ensuring precise bristle placement and uniform distribution, this technology helps to create toothbrushes that are more effective at removing plaque and preventing cavities. This level of quality control is essential in maintaining oral health and reducing the risk of dental problems in the long run.

Looking ahead, the future developments in toothbrush technology will likely focus on further enhancing the capabilities of the toothbrush tufting machine. Innovations such as artificial intelligence and machine learning could potentially be integrated into these machines, allowing for even greater levels of precision and customization in toothbrush production. Additionally, advancements in materials science may lead to the development of new types of bristles that are more effective at cleaning teeth and gums.

Overall, the toothbrush tufting machine represents a significant advancement in oral hygiene technology, with the potential to revolutionize the way toothbrushes are manufactured. By improving production efficiency, customization, and quality control, this technology is poised to set new standards for oral health products in the years to come. As the industry continues to evolve, the toothbrush tufting machine will undoubtedly play a crucial role in shaping the future of oral hygiene.

Conclusion

In conclusion, the Toothbrush Tufting Machine represents a significant advancement in the field of oral hygiene. By automating the tufting process, this innovative machine not only increases efficiency and accuracy but also opens up new possibilities for customization and creativity in toothbrush design. With its potential to revolutionize the way toothbrushes are manufactured, the Toothbrush Tufting Machine holds great promise for improving overall oral health worldwide. As we look towards the future, it is exciting to see how this technology will continue to shape the way we care for our teeth and gums.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019