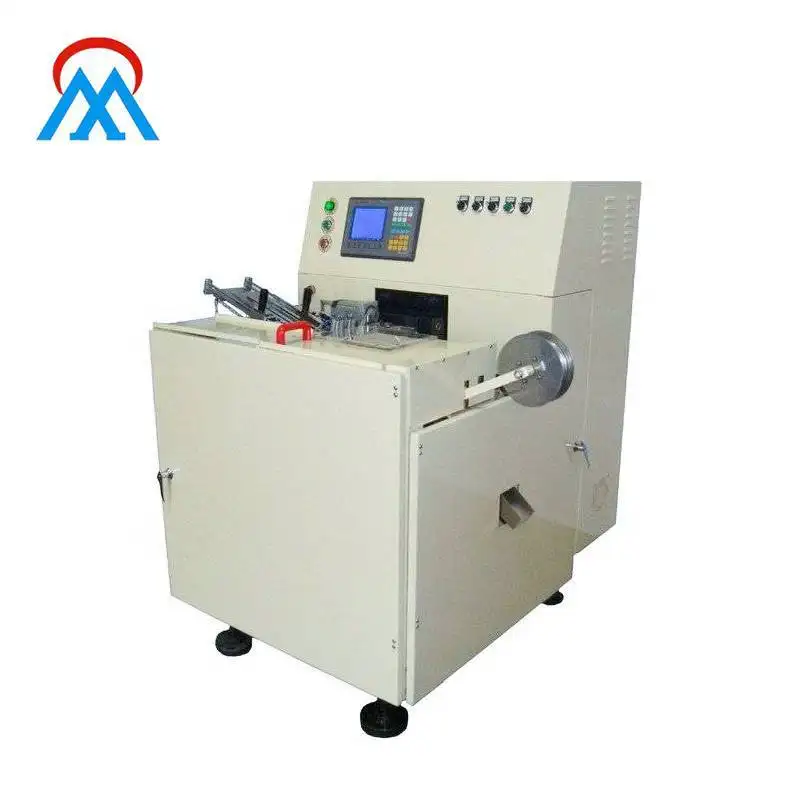

Optimize Selection of Toothbrush Tufting Machine for Better Performance

When selecting a toothbrush tufting machine, manufacturers should evaluate the machine based on specific parameters to ensure optimal performance.

Key Parameters to Evaluate

Speed and Feed Rate: The machines speed and feed rate determine its production efficiency and handling capacity. High-speed machines are ideal for high-volume production, while slower machines are suitable for delicate materials.

Precision and Accuracy: Precision is crucial for uniform bristle texture. Machines with high precision are essential for achieving premium product standards.

Material Handling Efficiency: The machine should handle a variety of materials, including natural and synthetic fibers, without causing wear or damage.

Durability and Maintenance Requirements: A durable machine with minimal maintenance needs is crucial for long-term production. Opt for machines with low downtime and easy-to-replace parts.

Energy Efficiency: With sustainability becoming a priority, consider machines that are energy-efficient and environmentally friendly.

Performance Metrics

Performance metrics are crucial for assessing the machines effectiveness:

- Cutting Capacity: The machines ability to process large batches without downtime is key for high-volume production.

Feed Adjustment: Precise feed rate adjustments are important for handling different materials and product specifications.

Oscillation Range: The machines oscillation range determines its flexibility in achieving desired bristle density and texture.

Noise and Vibration Levels: Lower noise and vibration levels enhance working conditions and reduce machine fatigue.

Durability and Maintenance Requirements

Durability is essential for long-term performance. Consider:

- Frame Structure: A robust frame ensures stability and prevents deformation.

Motor and Actuators: High-quality motors and actuators ensure precise and efficient operation.

Wear and Tear Components: Components like belts, pulleys, and bearings should be easy to maintain and replace.

Service Compatibility: The machine should be compatible with standard maintenance tools and procedures.

Material Selection

Material quality significantly affects the machines durability and performance:

- High-Quality Materials: Opt for stainless steel and durable plastics to resist wear and tear.

- Cleanability: Materials that are easy to clean and maintain are crucial for prolonged performance.

Ongoing Maintenance Strategies

Regular maintenance is essential for consistent performance:

- Preventive Maintenance: Scheduled inspections and lubrication prevent minor issues from becoming major problems.

Part Replacement: Promptly replace worn-out components to maintain stability and efficiency.

Environmental Control: Proper ventilation and temperature control prevent component degradation and extend the machines lifespan.

Comparative Analysis of Toothbrush Tufting Machine Models

Different models cater to various production needs. Heres a closer look at popular tufting machine models.

Exploring Different Models and Their Suitability

There are several types of toothbrush tufting machines, each designed for specific applications:

- Manual Tufting Machines: Simple and inexpensive, suitable for small-scale production but limited by speed and versatility.

Semi-Automatic Tufting Machines: Combine manual and automated elements, suitable for medium-scale production with balanced efficiency and simplicity.

Fully Automatic Tufting Machines: Ideal for high-volume production, offering minimal human intervention and high-speed operations.

High-Speed Tufting Machines: Designed for large-scale production, emphasizing high-speed output and efficiency.

Advantages and Limitations of Each Model

- Manual Tufting Machines:

Advantages: Low cost, easy to operate, suitable for small-scale production.

Limitations: Requires constant supervision, limited versatility, and higher costs for large-scale operations. - Semi-Automatic Tufting Machines:

Advantages: Faster production than manual machines, suitable for medium-scale operations.

Limitations: Still requires manual intervention, which can be time-consuming for complex tasks. - Fully Automatic Tufting Machines:

Advantages: High-speed production, minimal downtime, and low labor costs.

Limitations: Expensive upfront cost, complex setup, and potential for malfunctions if not maintained properly. - High-Speed Tufting Machines:

Advantages: Designed for high-volume production, ideal for manufacturers with large-scale operations.

Limitations: Requires advanced maintenance and expertise to operate effectively.

Real-World Applications of Toothbrush Tufting Machines

Companies that have optimized their production processes by investing in advanced machines can serve as valuable examples.

Example 1: Leading Oral Care Manufacturer in Asia

This company upgraded its tufting machine to a high-speed, fully automatic model, significantly reducing production time and increasing output. The machines advanced features, such as precise feed adjustment and low noise levels, ensured a consistent quality of tufted bristles.

Example 2: European Oral Care Giant

A European manufacturer selected a semi-automatic tufting machine to streamline its production line. The machines robust frame and efficient cutting capacity allowed the company to handle large batches of material with ease, reducing downtime and improving overall productivity.

Lessons Learned and Best Practices

- Key Lessons:

- Matching the machines specifications to the companys production needs and scale is critical for optimal performance.

- Regular maintenance and proper lubrication can significantly extend the machines lifespan.

- Investing in operator training can improve efficiency and reduce the likelihood of errors.

- Best Practices:

- Conduct a thorough evaluation of the machines specifications before making a purchase.

- Consider long-term costs of ownership, including maintenance and energy consumption.

- Explore upgrades to more advanced machines as production demands evolve.

Material Selection and Maintenance in Toothbrush Tufting Machines

Effective material selection and maintenance are crucial for achieving optimal performance and longevity.

Impact of Material Selection on Performance

Choosing high-quality materials, such as stainless steel and durable plastics, can enhance the machines durability and efficiency. Additionally, materials that are easy to clean and maintain prevent component degradation.

Ongoing Maintenance Strategies

Develop a comprehensive maintenance plan:

- Preventive Maintenance: Regular inspections and lubrication prevent minor issues from becoming major problems.

- Part Replacement: Timely replacement of worn-out components ensures the machine remains stable and efficient.

- Environmental Control: Proper ventilation and temperature control prevent component degradation and extend the machines lifespan.

Future Trends and Innovations in Toothbrush Tufting Machine Technology

Emerging technologies are shaping the future of the toothbrush tufting machine industry.

Emerging Trends in Tufting Machine Technology

AI-Driven Maintenance: Advanced AI algorithms predict potential failures and recommend maintenance schedules, reducing downtime.

Additive Manufacturing (3D Printing): This technology allows for custom components, improving precision and reducing material waste.

Potential for Automation and Integration

Fully Automated Production Lines: Integration with robotic systems can significantly enhance production speed and precision.

Integration with Industry 4.0: IoT sensors and smart machines provide real-time data for better decision-making.

Conclusion and Final Thoughts

Selecting the right toothbrush tufting machine is crucial for production efficiency, product quality, and profitability. Careful evaluation of parameters such as speed, precision, durability, and energy efficiency is essential. Advanced technologies like AI-driven maintenance and fully automated production lines are also transforming the industry.

By optimizing your choices and staying abreast of emerging trends, manufacturers can ensure they deliver high-quality products and remain competitive in the oral hygiene industry. Investing in innovation and robust maintenance practices can yield long-term benefits, enhancing both efficiency and product quality.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019