Manufacturer's Guide to Choosing the Right Toothbrush Tufting Machine

Understanding the importance of toothbrush tufting machines has become crucial for manufacturers aiming to deliver high-quality oral care products. Selecting the right machine is a decision that can significantly impact production efficiency, product quality, and market success.

Key Features to Look for in a Toothbrush Tufting Machine

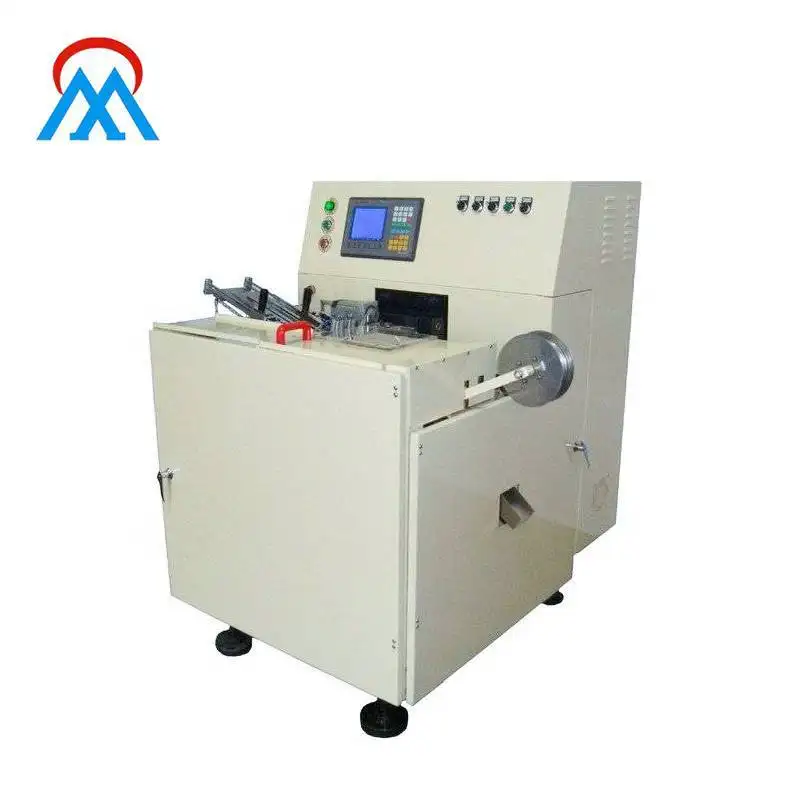

When selecting a tufting machine, several essential features should be at the forefront of your decision-making process. Modern machines boast advanced technological innovations designed to enhance accuracy and reduce downtime. Look for high-speed operation, precision control systems, and versatile tufting capabilities that can accommodate various brush designs. For instance, a manufacturer that adopted a machine with real-time monitoring reported a 15% reduction in waste due to consistent tufting quality.

Machines equipped with user-friendly interfaces and automated diagnostics can streamline operations and reduce the need for manual intervention. These features not only boost production efficiency but also improve the overall quality of the product. For example, a case study by the Oral Care Manufacturing Association highlighted a company that shifted to an automated system and saw a 20% increase in production capacity and a 25% reduction in labor costs.

Comparative Analysis: Manual vs. Automated Tufting Machines

The decision between manual and automated tufting systems is a critical one. Manual machines, while often less expensive, may fall short in terms of precision and speed, potentially leading to higher labor costs and lower output. In contrast, automated tufting machines offer superior efficiency and consistency. Studies have shown that automated systems can reduce manual error rates by up to 90%, improving product consistency and reducing waste.

A study by the Oral Care Manufacturing Association found that manufacturers using automated systems for tufting reported a 30% increase in production efficiency and a 20% reduction in operational costs. These results underscore the significant benefits of automated systems, especially for large-scale operations.

Evaluating Production Needs and Scalability

Understanding your current production needs and future scalability is paramount when choosing a tufting machine. Manufacturers should assess whether their chosen machine can handle existing demand while also being adaptable to future growth. A machine that offers scalability ensures that as your business expands, your production capabilities can seamlessly grow alongside it, without the need for significant additional investment.

For example, a mid-sized company that upgraded to a scalable tufting machine experienced a 40% increase in production capacity and was able to meet growing market demands without requiring additional machinery. Scalability not only ensures operational efficiency but also allows for better resource management and cost control.

Quality Control and Maintenance Considerations

Maintaining high standards of quality is non-negotiable in toothbrush manufacturing. Therefore, selecting a machine that facilitates rigorous quality control is essential. Look for features such as real-time monitoring systems and automated quality checks. Additionally, consider the ease of maintenance and availability of technical support. Machines that are easy to maintain and come with comprehensive support services can prevent costly downtime and extend the lifespan of your investment.

A manufacturer that installed a machine with advanced diagnostic features reported a 30% reduction in downtime and a 25% improvement in production efficiency. Regular maintenance can help prevent unexpected breakdowns, ensuring that your production process remains consistent and reliable.

Cost-Benefit Analysis: Investment vs. Long-term Gains

Investing in a high-quality tufting machine is a substantial financial commitment, but the long-term gains can far outweigh the initial costs. Conducting a thorough cost-benefit analysis is crucial. Consider factors such as reduced labor costs, increased production efficiency, and improved product quality when evaluating potential returns on investment.

For instance, a hypothetical scenario shows that a manufacturer who invested in a high-end tufting machine saw an initial investment of $20,000. Over five years, this investment resulted in a 20% reduction in labor costs and a 25% increase in production capacity, leading to a net return of $10,000 annually. This example underscores the financial benefits of making a smart investment in your production process.

Making Informed Decisions for Optimal Manufacturing

In conclusion, choosing the right toothbrush tufting machine is a decision that requires careful consideration of various factors, from technological features to production needs and financial implications. By prioritizing innovation, quality, and scalability, manufacturers can make informed choices that not only meet current operational demands but also position them for future success. With the right tufting machine, manufacturers can ensure their products stand out in a competitive market, driving growth and ensuring long-term profitability.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019