Analyze Efficient Toothbrush Tufting Machines

Toothbrush tufting is a crucial step in the manufacturing process where bristles are inserted into the toothbrush head. This task, once manual and labor-intensive, has been revolutionized by advanced tufting machines that enhance precision and speed. The drive for efficiency in production stems from the need to meet consumer demands while maintaining high-quality standards.

These machines are not just about speed; they are about precision and consistency. Traditional manual tufting required a skilled artisan to place each bristle carefully. However, toothbrush tufting machines have automated this process, significantly reducing the margin for error and increasing the speed of production. With the ability to produce high-quality, consistent toothbrushes at a faster rate, these machines have become indispensable in modern manufacturing processes.

Understanding the Mechanism of Toothbrush Tufting Machines

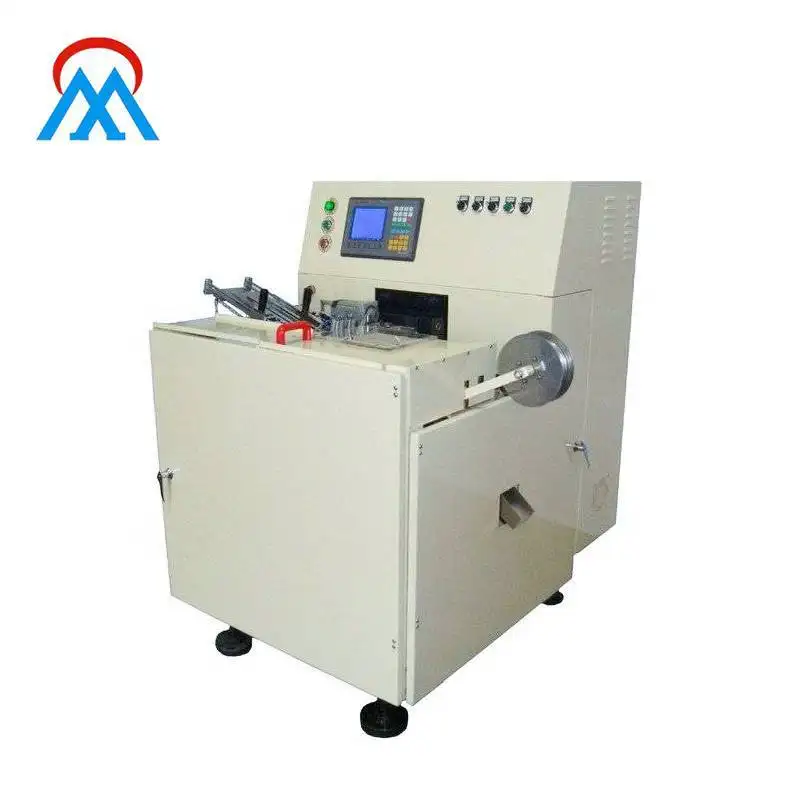

Toothbrush tufting machines operate by embedding bristles into pre-drilled holes on the toothbrush head. The mechanism involves complex automation and precise control, ensuring that each tuft is securely placed. Advances in technology have significantly enhanced the precision of tufting, allowing for a consistent and reliable end product.

The process begins with a series of pre-drilled holes on the toothbrush head. The machine then picks up the bristles and inserts them into the holes using a precise needle or tufting head. The placement is controlled by a combination of mechanical arms and computerized systems, ensuring that each tuft is accurately positioned and securely held in place. The technology behind these machines is sophisticated, with sensors and feedback systems that monitor the placement in real-time, making adjustments as needed.

By streamlining this process, advanced tufting machines have transformed the traditional tufting methods. The result is not only a more efficient and faster production line but also a higher-quality end product. The precision and consistency achieved with these machines have elevated the standards of toothbrush manufacturing, making them a critical component in meeting the diverse needs of consumers.

Evaluating Efficiency in Toothbrush Tufting

Efficiency in tufting machines is determined by several factors, including speed, accuracy, and reliability. Modern tufting machines have surpassed traditional methods by incorporating innovations such as computerized controls and robotic automation. These advancements allow for faster production cycles and reduced waste, ultimately boosting productivity.

Speed is a key factor in evaluating efficiency. Traditional manual tufting could take several hours to complete a single toothbrush head, whereas advanced tufting machines can complete the same task in minutes. This significant increase in speed not only reduces production time but also allows manufacturers to produce more toothbrushes in a given period, meeting the growing demand.

Accuracy is another crucial aspect. The precision of modern tufting machines ensures that each bristle is accurately placed, resulting in better performance and durability of the toothbrush. Unlike manual tufting, which can be affected by human error, these machines maintain consistent quality across every tuft.

Reliability is also important. Advanced tufting machines have low failure rates and are designed to operate for long periods without issues. This reliability means that manufacturers can rely on these machines to produce high-quality toothbrushes consistently, without the need for frequent downtime. The combination of speed, precision, and reliability makes advanced tufting machines an invaluable asset in modern manufacturing.

Impact of Efficient Tufting on Production Quality

Efficiency directly influences the quality of the toothbrushes produced. High-speed tufting machines ensure uniform tuft placement and density, which are critical for the performance and durability of the toothbrush. However, it is essential to balance speed with quality control to prevent defects that could compromise the products effectiveness.

Uniform tuft placement is crucial for maintaining the toothbrushs performance. Inconsistent tuft placement can lead to uneven brushing, which is not ideal for oral hygiene. Modern tufting machines use advanced sensors and feedback systems to monitor the placement of each tuft in real-time. Any deviation from the desired placement is immediately corrected, ensuring that every toothbrush produced meets the required quality standards.

Density is another important factor. The density of tufts affects the toothbrushs cleaning ability. Too few tufts can result in inadequate cleaning, while too many tufts can make the toothbrush uncomfortable to use. Advanced tufting machines can precisely control the number and density of tufts, ensuring that each toothbrush is optimized for performance.

Benefits of Investing in Advanced Tufting Machines

Investing in efficient tufting machines offers numerous economic advantages. These machines increase production capacity, reduce labor costs, and minimize downtime due to their low failure rates. Companies can achieve significant cost savings while meeting the high demand for diverse toothbrush designs, from electric to children's toothbrushes.

Increased production capacity is a key benefit. Advanced tufting machines can handle a larger volume of toothbrush production, enabling manufacturers to meet the growing demand for oral hygiene products. This capacity is crucial in a market where consumer interest in oral health is increasing, driving the need for more toothbrushes.

Reduced labor costs are another benefit. Traditional manual tufting requires a skilled workforce, which can be expensive. Tufting machines, on the other hand, can operate with minimal human intervention, reducing labor costs. This cost savings can be reinvested into other areas of the business, such as product development or marketing.

Minimized downtime is a significant advantage. Advanced tufting machines have low failure rates and are designed to operate continuously. This reliability means that manufacturers do not have to worry about unexpected breakdowns, which can cause production delays and cost additional expenses. By reducing downtime, these machines help maintain a steady production flow.

Challenges in Implementing Advanced Tufting Technology

Despite the benefits, transitioning to advanced tufting systems can present challenges. These may include the initial investment cost, the need for skilled operators, and potential integration issues with existing production lines. To overcome these obstacles, companies should focus on comprehensive training programs and phased implementation strategies.

Initial investment cost is a common concern. The cost of advanced tufting machines can be substantial, which can be a barrier for some manufacturers. However, the long-term benefits of increased efficiency and reduced costs make it worthwhile. Manufacturers should consider the return on investment (ROI) and plan for a phased transition, starting with a smaller scale implementation and gradually expanding.

The need for skilled operators is another challenge. While advanced tufting machines reduce the need for manual labor, they still require skilled operators to manage and maintain the machines. This may require additional training programs for existing staff or hiring new skilled workers. Comprehensive training programs can help bridge this skill gap and ensure that operators are proficient in using these machines.

Future Trends in Toothbrush Tufting Technology

The future of toothbrush tufting technology looks promising, with trends pointing towards further automation and digital integration. Innovations such as AI-driven quality control and IoT-enabled machines for real-time monitoring are on the horizon. These advancements promise even greater efficiency and flexibility in the production process.

AI-driven quality control is an exciting development. By integrating artificial intelligence, tufting machines can automatically detect and correct any issues during the production process. This real-time quality control ensures that every toothbrush produced meets the required standards, reducing the need for manual inspections and improving overall quality.

IoT-enabled machines for real-time monitoring are another significant advancement. These machines can provide real-time data on the production process, allowing manufacturers to make informed decisions and optimize the production line. The data collected can be used to identify trends, predict potential issues, and improve efficiency.

These innovations promise to make the manufacturing process even more efficient and flexible, enabling manufacturers to adapt quickly to changing market demands and consumer preferences. Incorporating these technologies not only enhances the performance of tufting machines but also positions manufacturers at the forefront of innovation.

Conclusion

In conclusion, efficient toothbrush tufting machines are vital to the success of the oral care industry. By embracing advanced tufting technology, manufacturers can enhance productivity, improve product quality, and maintain a competitive edge. As the industry evolves, staying ahead of technological trends will be crucial for continued success in meeting consumer needs.

The investment in these machines may seem daunting, but the benefits in terms of efficiency, quality, and cost savings make it a worthwhile endeavor. Companies that invest in advanced tufting machines can not only meet the growing demand for oral hygiene products but also ensure that each toothbrush is of the highest quality. As technology continues to advance, the future of toothbrush tufting looks bright, with continuous improvements in efficiency and quality that will revolutionize the industry.

By staying ahead in the oral care market, manufacturers can leverage these advancements to drive innovation and meet the evolving needs of consumers. Embracing the latest technologies not only enhances manufacturing processes but also contributes to the overall well-being and satisfaction of consumers.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019