How Technology Improves Toothbrush Tufting Machines

Toothbrush tufting machines have become indispensable tools in modern oral hygiene, ensuring a seamless and effective brushing experience for millions of users worldwide. These machines play a crucial role in shaping the tuft of the toothbrush, making it aerodynamic, comfortable, and effective for daily use. Recent technological advancements have revolutionized the way these machines operate, leading to improved efficiency, precision, and overall performance.

Introduction

Toothbrush tufting machines have become essential in the oral care industry, ensuring that the tufts of toothbrushes are aerodynamic, comfortable, and effective. These machines have evolved significantly in recent years, thanks to advances in technology. By integrating automation, utilizing advanced materials, and employing energy-efficient systems, these machines are now setting new standards in toothbrush manufacturing.

Automation in Toothbrush Tufting

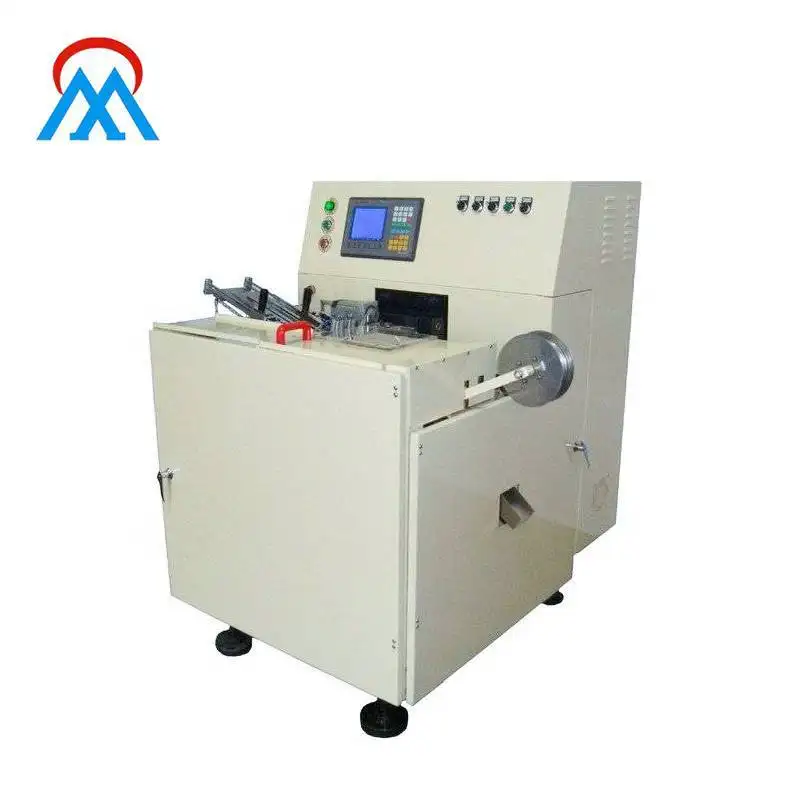

With the advent of automation, the future of tufting machines looks promising. Automation has transformed traditional tufting processes, which were once highly dependent on manual labor. Robotic arms and conveyor belts now move toothbrushes through various stages of tufting, ensuring precise and consistent results.

Robotic systems not only increase speed but also minimize the risk of human error. By performing tasks with precision, robots ensure that each toothbrush is manufactured to the highest standards. Automation also optimizes production, reducing waste and increasing efficiency. This level of consistency and efficiency is crucial for maintaining the quality and reliability of toothbrushes.

Material Science Innovations

Material science has made significant strides in enhancing toothbrush tufting machines. Traditional materials like basic plastics and polymers were once the norm but lacked the durability and hygiene properties needed for modern toothbrushes.

Modern tufting machines utilize advanced materials such as biocompatible polymers and high-performance synthetic resins. These materials not only enhance durability and resistance to wear and tear but also improve the hygiene of toothbrushes by repelling water and bacteria. Additionally, these materials maintain the shape and flexibility of the tuft, ensuring that toothbrushes remain effective for extended periods.

For instance, biocompatible polymers are designed to be gentle on the user's gums and teeth, reducing the risk of irritation. High-performance synthetic resins offer superior strength and flexibility, making the tuft more resilient and resistant to breakage. By using these advanced materials, manufacturers can produce toothbrushes that are both effective and comfortable.

Energy Efficiency and Sustainability

Energy efficiency is another critical area where technology has made significant strides. As consumers and manufacturers increasingly focus on sustainability, toothbrush tufting machines are being designed to optimize energy usage.

Advanced sensors and motor controls monitor the machine's performance, adjusting settings to ensure maximum efficiency. By reducing energy waste, these machines not only save money for manufacturers but also contribute to a smaller environmental footprint. Sustainable practices are becoming more important in the manufacturing industry, and toothbrush tufting machines that prioritize energy efficiency and sustainability are gaining more attention.

Machine Learning and AI in Tufting

Machine learning and AI have become integral parts of modern toothbrush tufting machines. These technologies optimize the tufting process, improve machine performance, and even predict maintenance needs.

AI systems analyze data from various sources, such as production logs, material specifications, and performance metrics. By identifying patterns and trends, they enable manufacturers to make data-driven decisions that enhance efficiency and reduce waste. AI also helps predict maintenance requirements, ensuring that machines operate at peak performance. By monitoring data from sensors and other sources, these systems can detect potential issues before they arise, minimizing downtime and improving overall productivity.

Consumer Benefits of Improved Tufting Machines

The advancements in toothbrush tufting machines undoubtedly benefit consumers. With more precise and durable tufting, consumers enjoy a better brushing experience. The use of high-quality materials ensures that toothbrushes not only remain effective but are also comfortable to use.

Faster production times due to automation mean that consumers can access higher-quality toothbrushes at lower costs. Additionally, sustainable materials and energy-efficient machines contribute to a smaller environmental footprint, aligning with the growing demand for eco-friendly products among consumers.

For those who prioritize oral hygiene, toothbrush tufting machines that incorporate the latest technology offer a more convenient and effective solution for maintaining good dental health. These advancements ensure that each toothbrush is manufactured with the utmost care, guaranteeing a superior brushing experience.

The Future of Toothbrush Tufting Technology

The future of toothbrush tufting technology is promising. As technology continues to advance, we can anticipate even more innovative solutions in toothbrush production. An emerging trend is the use of AI-driven tools to personalize tufting experiences. By analyzing data from individual users, AI systems can tailor tufting processes to meet unique needs, potentially leading to more personalized and effective brushing experiences.

Additionally, there is growing interest in machines inspired by nature. Some companies are developing toothbrush tufting machines that use organic materials or innovative manufacturing techniques to mimic natural processes. These advancements could revolutionize toothbrush production, offering new possibilities for quality and sustainability.

Conclusion

As technology continues to advance, the future of toothbrush tufting machines looks bright. With ongoing innovations, manufacturers and consumers can look forward to a future where toothbrush tufting machines are even more precise and efficient, enhancing both the effectiveness and convenience of oral hygiene. These advancements ensure that toothbrushes are manufactured with the utmost care, providing users with a better brushing experience and improved dental health.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019