Revolutionizing Oral Hygiene: The Ultimate Guide To The Toothbrush Tufting Machine

Are you ready to revolutionize your oral hygiene routine? Look no further than the Toothbrush Tufting Machine – the cutting-edge technology that is changing the way we brush our teeth. In this ultimate guide, we will explore how this innovative machine is transforming the dental industry and taking toothbrush design to the next level. Join us as we dive into the world of toothbrush tufting and discover how you can achieve the perfect smile with the help of this groundbreaking tool.

- Introduction to Toothbrush Tufting Machines

to Toothbrush Tufting Machines

Toothbrush tufting machines have revolutionized the way toothbrushes are manufactured, making it easier and more efficient to produce high-quality oral hygiene products. These machines play a crucial role in the process of assembling toothbrushes, ensuring that the bristles are securely attached to the brush head.

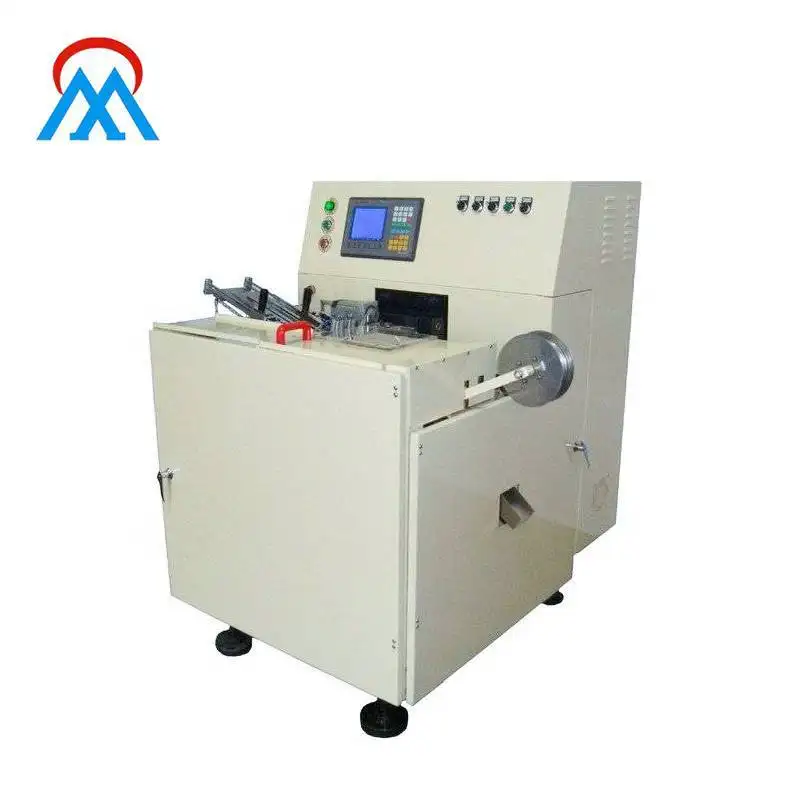

The toothbrush tufting machine is a complex piece of equipment that consists of various components and mechanisms designed to automate the tufting process. These machines are typically used in large-scale manufacturing facilities where toothbrushes are produced in bulk. They are capable of tufting thousands of toothbrushes per hour, making them essential tools for the oral care industry.

One of the key components of a toothbrush tufting machine is the tufting head, which is responsible for inserting and securing the bristles into the brush head. The tufting head is equipped with hundreds of small needles that move up and down rapidly to insert the bristles into pre-drilled holes in the brush head. This process requires precision and accuracy to ensure that the bristles are evenly distributed and securely attached.

In addition to the tufting head, toothbrush tufting machines also feature a bristle feeding system, which supplies the machine with a continuous stream of bristles. These bristles are typically made from nylon or other synthetic materials and come in various lengths and colors. The bristle feeding system is crucial for ensuring that the machine can tuft toothbrushes of different sizes and specifications.

Furthermore, toothbrush tufting machines are equipped with sensors and controls that monitor the tufting process and make adjustments as needed. These sensors ensure that the bristles are inserted correctly and that any issues or malfunctions are detected and addressed promptly. This level of automation helps to streamline the manufacturing process and minimize the risk of defects or errors.

Overall, toothbrush tufting machines have significantly improved the efficiency and reliability of toothbrush production. By automating the tufting process, manufacturers can produce high-quality toothbrushes with consistent results. These machines have revolutionized the oral hygiene industry, making it easier for consumers to access affordable and reliable oral care products.

In conclusion, toothbrush tufting machines play a critical role in the manufacturing of toothbrushes, ensuring that the bristles are securely attached to the brush head. These machines are equipped with advanced technology and automation features that enable them to tuft thousands of toothbrushes per hour with precision and accuracy. As the demand for oral hygiene products continues to grow, toothbrush tufting machines will remain essential tools for manufacturers looking to produce high-quality toothbrushes efficiently.

- The Evolution of Oral Hygiene Technology

In the world of oral hygiene, technology has played a crucial role in revolutionizing the way we care for our teeth and gums. One of the most important advancements in this field is the development of the toothbrush tufting machine. This innovative piece of equipment has completely transformed the manufacturing process of toothbrushes, making them more efficient, durable, and effective than ever before.

The toothbrush tufting machine is a sophisticated piece of machinery that is used to attach bristles to the head of a toothbrush. This process is crucial in determining the quality and effectiveness of the toothbrush, as the bristles need to be securely attached to the head in order to effectively clean the teeth and gums.

Before the invention of the toothbrush tufting machine, toothbrush bristles were attached by hand, a labor-intensive and time-consuming process that often resulted in inconsistent bristle placement and poor overall quality. However, with the introduction of the tufting machine, manufacturers were able to produce toothbrushes at a much faster rate and with much greater precision.

The evolution of the toothbrush tufting machine has been a game-changer in the oral hygiene industry. Not only has it made toothbrush production more efficient, but it has also allowed for the development of new and innovative toothbrush designs. Manufacturers can now experiment with different bristle patterns, densities, and materials, resulting in toothbrushes that are tailored to meet the specific needs of consumers.

In addition to improving the quality of toothbrushes, the toothbrush tufting machine has also had a positive impact on the environment. By streamlining the manufacturing process, manufacturers are able to reduce waste and minimize the use of harmful chemicals. This environmentally friendly approach has made the toothbrush tufting machine an essential tool for any modern toothbrush manufacturing facility.

Furthermore, the toothbrush tufting machine has paved the way for the development of high-tech toothbrushes that incorporate advanced features such as oscillating bristles, built-in timers, and pressure sensors. These next-generation toothbrushes are designed to provide a more thorough and effective cleaning experience, helping consumers maintain optimal oral health.

Overall, the toothbrush tufting machine represents a significant milestone in the evolution of oral hygiene technology. Its impact on the industry has been far-reaching, leading to the development of more efficient, durable, and effective toothbrushes. As technology continues to advance, we can only imagine the exciting innovations that lie ahead in the world of oral care.

- How Toothbrush Tufting Machines Work

In recent years, advancements in technology have completely revolutionized oral hygiene practices. One of the key innovations that have significantly impacted the industry is the toothbrush tufting machine. These machines play a crucial role in the production of toothbrushes, ensuring that each bristle is securely attached to the brush head to provide users with an effective cleaning experience.

To understand how toothbrush tufting machines work, it is essential to first grasp the basic components of these machines. The primary parts of a toothbrush tufting machine include the feeding system, cutting system, tufting system, and trimming system. Each of these components plays a specific role in the tufting process, working together seamlessly to create high-quality toothbrushes.

The first step in the tufting process is the feeding system, which consists of a conveyor belt that transports raw materials, such as plastic handles and bristles, to the machine. The materials are then fed into the cutting system, where they are precisely cut to the desired length for the toothbrush. This step is crucial in ensuring that each toothbrush has uniform bristle length for consistent cleaning performance.

Once the materials are cut to size, they are moved to the tufting system, where bristles are inserted into the brush head. The tufting system utilizes a series of needles that quickly and accurately punch the bristles into the brush head, securing them in place. This step requires precision and speed to ensure that the tufting process is completed efficiently.

After the bristles are tufted into the brush head, the trimming system comes into play. This system trims any excess bristles to create a smooth and uniform surface on the toothbrush. This step not only enhances the appearance of the toothbrush but also ensures that it is safe for use, as any sharp or uneven bristles can cause irritation to the gums.

Overall, toothbrush tufting machines are essential in the production of high-quality toothbrushes. These machines streamline the manufacturing process, allowing for mass production of toothbrushes that meet stringent quality standards. By automating the tufting process, toothbrush tufting machines ensure consistency in bristle placement, bristle length, and overall toothbrush performance.

In conclusion, toothbrush tufting machines have transformed the oral hygiene industry, making it possible to produce high-quality toothbrushes efficiently and effectively. These machines play a vital role in ensuring that users receive a reliable and consistent cleaning experience with every use. As technology continues to advance, toothbrush tufting machines will likely play an even more significant role in shaping the future of oral hygiene.

- Benefits of Using Toothbrush Tufting Machines

The toothbrush tufting machine has revolutionized the way toothbrushes are manufactured, making it easier and more efficient to produce high-quality oral hygiene products. In this ultimate guide, we will delve into the benefits of using toothbrush tufting machines and how they are changing the game in oral care.

One of the key advantages of toothbrush tufting machines is their ability to automate the process of tufting, which is the process of attaching bristles to the toothbrush head. This reduces the need for manual labor and increases productivity, allowing manufacturers to produce a larger quantity of toothbrushes in a shorter amount of time. This automation also helps to ensure consistency in the quality of the toothbrushes, as each one is made with precision and accuracy.

Furthermore, toothbrush tufting machines are versatile and can accommodate a wide range of toothbrush designs and styles. Whether it's a soft-bristled toothbrush for sensitive gums or a firm-bristled toothbrush for thorough cleaning, these machines can handle it all. This flexibility allows manufacturers to cater to a diverse market and meet the needs of different consumers.

Another benefit of using toothbrush tufting machines is the cost savings they offer. By streamlining the production process and reducing the need for manual labor, manufacturers can lower their operating costs and ultimately reduce the price of their toothbrushes. This makes high-quality oral care more accessible to a larger population, ultimately contributing to improved overall dental health.

In addition to these benefits, toothbrush tufting machines also promote sustainability in oral care manufacturing. By optimizing the production process and minimizing waste, these machines help reduce the environmental impact of toothbrush manufacturing. This is especially important in today's society, where sustainability is a top priority for many consumers.

Overall, the toothbrush tufting machine is a game-changer in the oral care industry. Its ability to automate the tufting process, accommodate a variety of toothbrush designs, reduce costs, and promote sustainability make it an essential tool for manufacturers looking to stay competitive in the market. With the use of these machines, the future of oral hygiene looks bright and promising.

- Future Innovations in Oral Hygiene Technology

In recent years, technological advancements have revolutionized the field of oral hygiene, leading to the development of innovative products and tools that have transformed the way we take care of our teeth and gums. One of the key players in this transformation is the toothbrush tufting machine, a cutting-edge device that has completely changed the way toothbrushes are manufactured. In this ultimate guide, we will explore the future innovations in oral hygiene technology brought about by the toothbrush tufting machine.

The toothbrush tufting machine is a sophisticated piece of equipment that is used to automate the process of inserting bristles into toothbrush heads. This machine has brought about significant advancements in oral hygiene technology by allowing for the mass production of high-quality toothbrushes with precision and efficiency. By using the toothbrush tufting machine, manufacturers are able to produce toothbrushes with uniform bristle placement, ensuring a consistent cleaning experience for consumers.

One of the key innovations of the toothbrush tufting machine is its ability to produce toothbrushes with various bristle configurations, such as soft, medium, and hard bristles, to cater to the diverse needs of consumers. This level of customization has never been possible before the introduction of the toothbrush tufting machine, allowing individuals to choose a toothbrush that best suits their oral health needs.

Furthermore, the toothbrush tufting machine has also revolutionized the manufacturing process by significantly reducing production time and costs. Previously, toothbrush manufacturing was a labor-intensive process that required skilled labor to insert bristles manually. With the toothbrush tufting machine, manufacturers are able to produce toothbrushes in a fraction of the time, leading to increased productivity and cost savings.

In addition to its efficiency and precision, the toothbrush tufting machine has also paved the way for eco-friendly innovations in oral hygiene technology. With the growing concern for environmental sustainability, manufacturers are now using biodegradable materials for toothbrush bristles, such as bamboo or corn-based plastics, which can be easily inserted into toothbrush heads using the toothbrush tufting machine. This shift towards eco-friendly materials is not only beneficial for the environment but also for the health of consumers, as it reduces their exposure to harmful chemicals found in traditional plastic bristles.

Overall, the toothbrush tufting machine represents a significant milestone in the evolution of oral hygiene technology. Its ability to automate the manufacturing process, produce customized toothbrushes, and promote eco-friendly practices is shaping the future of oral care. As technology continues to advance, we can expect even more innovations in oral hygiene technology to emerge, further improving the way we take care of our teeth and gums.

Conclusion

In conclusion, the Toothbrush Tufting Machine truly is revolutionizing oral hygiene by providing a more efficient and precise method for creating toothbrushes. With its advanced technology and ability to produce high-quality products, this machine is paving the way for a new standard in oral care. By investing in this innovative tool, dental professionals can ensure that their patients are receiving the best possible products for maintaining healthy teeth and gums. So, if you want to stay ahead in the oral hygiene industry, consider incorporating the Toothbrush Tufting Machine into your production process and experience the benefits for yourself. Say goodbye to outdated methods and hello to a more effective way of creating toothbrushes that will keep smiles bright and healthy for years to come.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019