The Ultimate Guide To Broom Tufting Machines: How To Choose The Best One For Your Needs

Are you in the market for a new broom tufting machine but feeling overwhelmed by the options available? Look no further! Our comprehensive guide has everything you need to know to choose the best machine for your specific needs. From understanding different types of broom tufting machines to key factors to consider when making your selection, we've got you covered. So, let's dive in and find the perfect broom tufting machine for you!

- Understanding the Purpose of Broom Tufting Machines

Broom tufting machines are small but powerful tools used in the manufacturing of brooms. These machines play a crucial role in the production process as they are responsible for creating the tufts or bristles that make up the broom's sweeping surface. Understanding the purpose of broom tufting machines is essential for anyone looking to invest in one for their manufacturing needs.

Broom tufting machines are used to securely attach the bristles to the broom's base, ensuring a durable and effective sweeping tool. The tufting process involves feeding the bristles through the machine, which then secures them in place through a combination of cutting, clamping, and stitching mechanisms. This results in a tight, uniform pattern of bristles that provide optimal sweeping performance.

Choosing the best broom tufting machine for your needs involves considering a few key factors. These include the type of broom you are manufacturing, the desired tufting pattern, and the level of automation required. Some machines offer advanced features such as programmable settings, multiple tufting heads, and adjustable tufting speed, making them suitable for high-volume production.

When selecting a broom tufting machine, it is essential to consider the tufting pattern that best suits your broom design. Common tufting patterns include straight, staggered, and random tufting, each offering unique benefits depending on the intended use of the broom. For example, straight tufting provides a neat and uniform appearance, while staggered tufting offers better coverage and durability.

Another important factor to consider when choosing a broom tufting machine is the level of automation desired. Fully automated machines offer increased efficiency and consistency in the tufting process, reducing the need for manual labor and minimizing the risk of human error. Semi-automated machines, on the other hand, provide more flexibility and control over the tufting process, allowing for customization and adjustment as needed.

In conclusion, understanding the purpose of broom tufting machines is essential for anyone looking to invest in one for their manufacturing needs. These machines play a crucial role in the production of brooms, ensuring a durable and effective sweeping tool. By considering factors such as tufting pattern, automation level, and production volume, you can choose the best broom tufting machine to meet your specific needs and maximize efficiency in your manufacturing process.

- Factors to Consider When Choosing a Broom Tufting Machine

Broom tufting machines are essential tools for manufacturers in the broom-making industry. These machines play a crucial role in creating high-quality brooms efficiently and effectively. When it comes to choosing the best broom tufting machine for your needs, there are several factors to consider to ensure that you make the right decision.

First and foremost, the type of broom tufting machine you choose will depend on the volume of production you require. Different machines are designed to handle varying capacities, so it's important to assess your production needs before making a purchase. If you have a small to medium-sized operation, a compact broom tufting machine may be sufficient. However, for larger-scale production, you may need a more robust and high-capacity machine.

Another important factor to consider when choosing a broom tufting machine is the type of brooms you will be producing. Different machines are designed to accommodate different broom styles, sizes, and materials. Whether you are making traditional corn brooms, flat brooms, or angled brooms, it's essential to select a machine that can handle the specific requirements of your production line.

In addition to the type of brooms you will be producing, the quality of the broom tufting machine is also a critical factor to consider. Look for a machine that is durable, reliable, and easy to maintain. Investing in a high-quality machine will not only ensure consistent and precise results but also reduce downtime and maintenance costs in the long run.

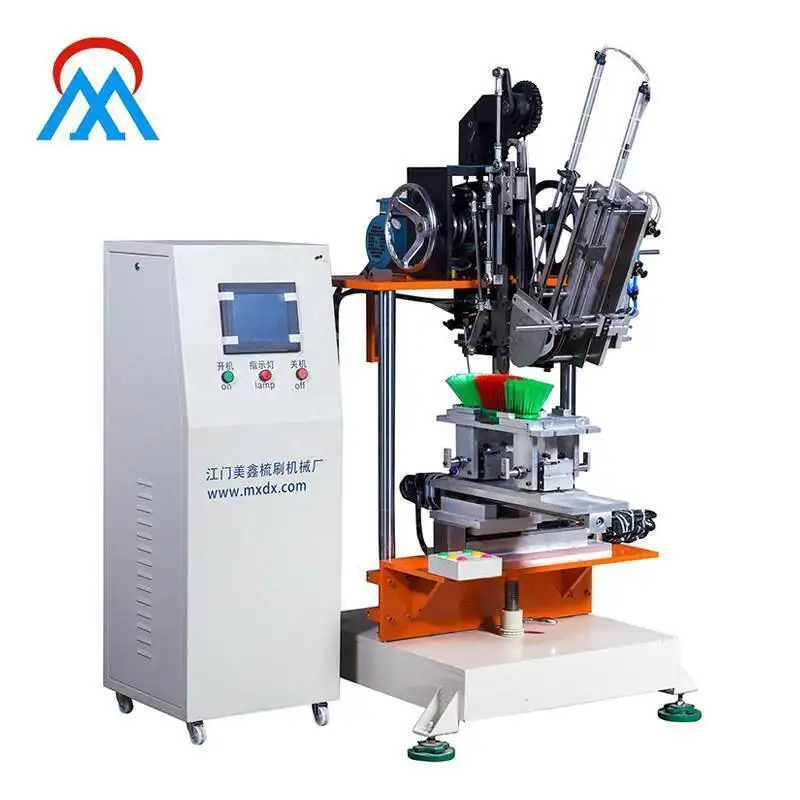

When choosing a broom tufting machine, it's also important to consider the level of automation and technology available. Some machines come equipped with advanced features such as touchscreen interfaces, programmable settings, and automatic adjustment capabilities. These advanced technologies can streamline the production process, improve efficiency, and enhance the overall quality of your brooms.

Furthermore, the cost of the broom tufting machine is another important consideration. While it's essential to invest in a high-quality machine, it's also important to consider your budget and determine the best value for your money. Compare prices, features, and warranties from different manufacturers to find a machine that meets your needs and fits within your budget.

In conclusion, choosing the best broom tufting machine for your needs requires careful consideration of various factors such as production volume, broom type, quality, technology, and cost. By taking these factors into account and conducting thorough research, you can select a machine that will help you produce high-quality brooms efficiently and effectively. Invest in the right broom tufting machine, and watch your production line flourish.

- Types of Broom Tufting Machines Available on the Market

Broom tufting machines are essential tools in the manufacturing of high-quality brooms. They are designed to efficiently and effectively tuft bristles into broom heads, ensuring that the bristles are securely fastened and will not come loose during use. When it comes to choosing the best broom tufting machine for your needs, there are several types available on the market to consider.

One common type of broom tufting machine is the automatic tufting machine. This type of machine is highly efficient and can tuft a large number of broom heads in a short amount of time. Automatic tufting machines are ideal for high-volume production environments where speed and consistency are key. These machines often feature advanced technology such as computer-controlled systems that can easily adjust settings and patterns to meet specific tufting requirements.

Another type of broom tufting machine is the semi-automatic tufting machine. These machines require some manual intervention from an operator but still offer a high level of efficiency and precision. Semi-automatic tufting machines are versatile and can be easily adjusted to tuft different types of brooms. They are a cost-effective option for smaller production facilities or businesses that do not require the same level of automation as automatic tufting machines.

For smaller operations or businesses looking for a more budget-friendly option, manual tufting machines are also available. These machines require the most manual labor but are still capable of producing high-quality broom heads. Manual tufting machines are simple to operate and maintain, making them a great option for beginners or those with limited production needs.

When choosing a broom tufting machine, it is important to consider factors such as the size of your production facility, the volume of brooms you need to tuft, and your budget. It is also important to consider the type of brooms you will be producing, as different machines may be better suited for certain types of bristles or patterns.

Ultimately, the best broom tufting machine for your needs will depend on your specific requirements and preferences. By considering the types of broom tufting machines available on the market and evaluating their features and capabilities, you can choose a machine that will help you produce high-quality brooms efficiently and effectively.

- Comparing Features and Specifications of Different Broom Tufting Machines

Broom tufting machines are essential tools in the manufacturing of brooms, allowing for the efficient and precise tufting of bristles onto broom bases. When choosing a broom tufting machine, it is important to consider various features and specifications to ensure that you select the best one for your needs.

One of the key factors to consider when comparing broom tufting machines is the tufting speed. This refers to the rate at which the machine can tuft bristles onto a broom base. Machines with higher tufting speeds are able to produce brooms at a faster pace, increasing overall production efficiency. However, it is important to balance speed with quality, as faster machines may sacrifice precision in tufting.

Another important feature to consider is the number of tufting heads on the machine. Machines with multiple tufting heads can tuft multiple brooms simultaneously, further increasing production efficiency. Additionally, machines with adjustable tufting heads allow for customization and flexibility in tufting patterns and designs.

Furthermore, the type of bristles that the machine can tuft is a critical factor to consider. Different broom tufting machines are designed to work with specific types and sizes of bristles, so it is important to choose a machine that is compatible with the bristles you plan to use in your brooms.

In addition to these features, it is important to consider the overall build quality and durability of the broom tufting machine. Machines constructed with high-quality materials and components are more likely to withstand the rigors of continuous use and provide reliable performance over time. Additionally, machines with easy-to-use controls and a user-friendly interface can streamline the tufting process and make operation more efficient.

When comparing broom tufting machines, it is also important to consider the level of technical support and after-sales service provided by the manufacturer. Choosing a machine from a reputable manufacturer with a strong track record of customer support can help ensure that any issues or challenges that arise with the machine can be addressed promptly and effectively.

In conclusion, selecting the best broom tufting machine for your needs involves considering a range of features and specifications, including tufting speed, number of tufting heads, compatibility with bristles, build quality, and technical support. By carefully comparing these factors, you can choose a machine that meets your production requirements and helps you create high-quality brooms efficiently and effectively.

- Tips for Making the Right Decision on Which Broom Tufting Machine to Purchase

When it comes to choosing the right broom tufting machine for your needs, there are several key factors to consider. From the type of tufting machine to the features it offers, making the right decision can make all the difference in the efficiency and quality of your production process. In this comprehensive guide, we will provide you with expert tips and advice on how to select the best broom tufting machine for your specific requirements.

First and foremost, it is essential to understand the different types of broom tufting machines available on the market. There are two main types of tufting machines – single-head and multi-head machines. Single-head machines are ideal for smaller production runs and offer more flexibility in terms of design and customization. On the other hand, multi-head machines are better suited for larger production volumes and can significantly increase productivity.

When choosing a broom tufting machine, it is crucial to consider the features and capabilities of the machine. Some key features to look out for include the number of needles, stitching speed, and stitch length. The number of needles on a tufting machine will determine the density and thickness of the tufting, while the stitching speed will impact the overall productivity of the machine. Additionally, the stitch length can affect the overall appearance and durability of the broom tufting.

In addition to the technical specifications of the machine, it is also important to consider the reputation and reliability of the manufacturer. Look for a company with a proven track record of producing high-quality tufting machines and providing excellent customer support. Reading reviews and testimonials from other customers can also provide valuable insights into the performance and reliability of a particular tufting machine.

Another important factor to consider when choosing a broom tufting machine is your specific production requirements. Consider factors such as the size and thickness of the broom tufting you will be producing, as well as the desired output volume. Choosing a machine that is tailored to your specific requirements will ensure optimal performance and efficiency in your production process.

In conclusion, selecting the right broom tufting machine is crucial for the success of your production process. By considering factors such as the type of machine, key features, manufacturer reputation, and production requirements, you can make an informed decision that will meet your needs and provide you with a reliable and efficient tufting machine. With the tips and advice provided in this guide, you can confidently choose the best broom tufting machine for your specific requirements and take your production process to the next level.

Conclusion

In conclusion, choosing the best broom tufting machine for your needs is a crucial decision that can greatly impact the efficiency and quality of your broom production. By considering factors such as production capacity, tufting speed, and machine durability, you can ensure that you invest in a machine that will meet your specific requirements and help you achieve success in your broom-making endeavors. With the ultimate guide to broom tufting machines at your disposal, you can confidently navigate the market and make an informed decision that will propel your business to new heights. Happy tufting!

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019