Broom Tufting Machine Manufacturer Shares Top Tips for Beginners

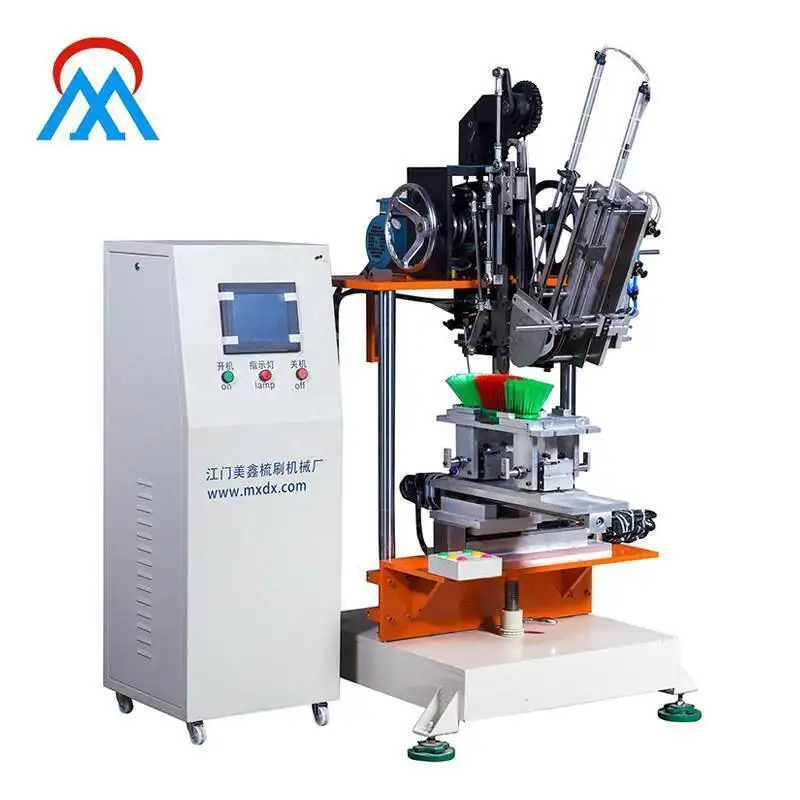

Are you fascinated by the art of creating sturdy, functional brushes that grace thousands of households? If so, dive into the world of broom tufting machines! These industrial wonders transform a simple bundle of bristles into a durable, high-quality broom that can withstand daily use with ease. Whether you're a seasoned manufacturer or a complete beginner, understanding the significance and applications of these machines is key. These tools aren't just about efficiency; they also offer endless possibilities for design and functionality.

Getting Started: Choosing the Right Broom Tufting Machine

Selecting the right broom tufting machine can be a daunting task, especially for novices. With so many options on the market, it's crucial to know what to look for. When deciding on a machine, consider the type of brushes you intend to produce, the volume of production, and the specific features that suit your operational needs.

Key Features to Consider

- Type of Bristles: Different types of brushes require specific machines. Popular models like the XYZ-1000 and ABC-500 are known for their versatility and durability.

- Tufting Axes: The number of tufting axes is crucial. Machines like the DEF-2000 offer three axes, providing greater precision and flexibility.

- Ease of Maintenance: Look for machines with easy-to-replace parts and straightforward cleaning procedures. Machines like the GHI-4000 are known for their user-friendly design.

- Compatibility with Materials: Ensure the machine can handle your preferred bristle materials, such as hogs hair, horsehair, and synthetic blends.

Setting Up: Essential Preparation and Installation Tips

Setting up a broom tufting machine is no small feat, but with these step-by-step instructions, you can ensure a smooth installation process.

Checklist for Setup

- Inspect Components: Verify that all parts are present and in working condition.

- Position the Machine: Securely place the machine on a level surface.

- Connect Power Supplies: Ensure the machine is correctly connected to a stable power source.

- Calibrate Tufting Heads: Adjust the tufting heads to ensure precise placement.

Common Mistakes to Avoid

- Neglecting Safety Checks: Always perform a thorough safety check before starting the machine.

- Improper Alignment: Ensure that all parts are aligned correctly to avoid malfunctions.

Operational Insights: Mastering the Basics of Broom Tufting

Operating a broom tufting machine is more than just powering it on and inserting some bristles. It involves mastering basic techniques to achieve consistent and high-quality tufting.

Real-World Scenario

Imagine creating a household broom for a bustling kitchen. Consistency in tufting is crucial to ensure the bristles maintain their shape and effectiveness. By carefully controlling the tuft density and brush patterns, you can create a durable broom that withstands heavy use.

Tips for Mastery

- Familiarize Yourself with the Control Panel: Understand the functions of each button and switch.

- Practice Tufting Techniques: Adjust settings to optimize tuft density and pattern alignment.

- Regular Calibration: Regularly calibrate the machine to ensure consistent output.

Troubleshooting: Common Issues and Solutions

Just like any machine, broom tufting machines can encounter issues. Here are some common problems and their simple solutions.

Scenario: Machine Jam

Scenario: A user encounters a machine jam while tufting brushes.

Step-by-Step Solution:

1. Erase Power Source: Cut off the power to the machine.

2. Disassemble for Inspection: Carefully open the machine and check for any caught or misaligned parts.

3. Clean and Lubricate: Clean and lubricate the affected areas.

4. Reassemble and Repeat: Reassemble the machine and perform a thorough check before restarting.

Regular Maintenance

- Cleaning: Regularly clean the machine and its parts to prevent debris buildup.

- Lubrication: Ensure all moving parts are well-lubricated to maintain smooth operation.

Advanced Techniques: Enhancing Your Broom Tufting Skills

Once you've mastered the basics, it's time to explore advanced techniques. These can elevate your manufacturing capabilities and allow you to create innovative, high-quality brooms.

Example: Intricate Designs

Imagine creating a specialized broom designed for outdoor use, featuring intricate patterns that enhance its durability and beauty. By manipulating tuft density and brush types, you can push the boundaries of traditional broom tufting.

Tips for Advanced Techniques

- Innovative Designs: Experiment with different tuft density and brush types to create unique designs.

- Multiaxial Machines: Use machines with multiple tufting axes for greater precision and flexibility.

- Creative Patterns: Explore new patterns and designs to stand out in the market.

Embracing the Learning Curve

Mastering broom tufting machines is a journey, and it's filled with both challenges and rewarding experiences. By choosing the right machine, setting it up correctly, and practicing operational techniques, you can confidently navigate the learning curve. Embrace the challenges of troubleshooting and the endless possibilities of advanced techniques, and you'll be well on your way to creating high-quality brooms that stand the test of time. Investing time in learning these techniques will not only increase your productivity but also set you apart in the brush manufacturing industry.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019