The Innovation Of Broom Tufting Machines: Efficiency And Precision In Manufacturing

Welcome to our article on the innovation of broom tufting machines. In today's fast-paced manufacturing industry, efficiency and precision are key factors in ensuring high-quality products are produced in a timely manner. Broom tufting machines have revolutionized the way brooms are manufactured, allowing for greater consistency and accuracy in tufting operations. Join us as we explore the advancements in broom tufting technology and how it is shaping the future of manufacturing.

Improving Traditional Broom Manufacturing Techniques

In recent years, there has been a significant shift in the way brooms are manufactured, with a particular focus on improving traditional broom making techniques. This shift has been made possible through the innovation of broom tufting machines, which have revolutionized the industry by increasing efficiency and precision in the manufacturing process.

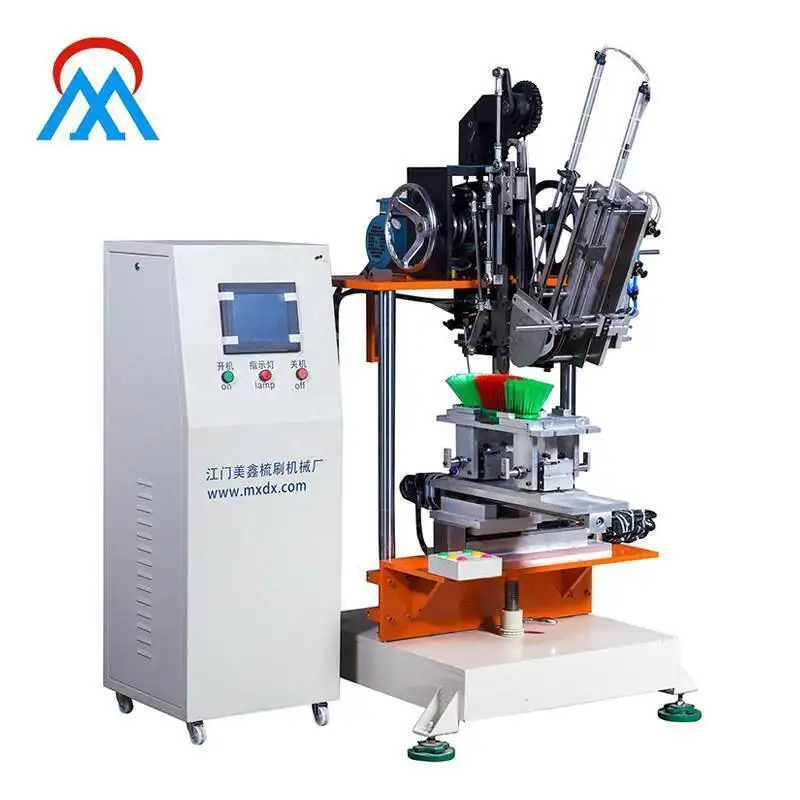

Broom tufting machines have become an essential tool in the production of brooms, as they allow for the automated tufting of bristles onto broom heads. This mechanized process can produce a large quantity of brooms in a fraction of the time it would take using traditional methods. This not only increases production output but also ensures a consistent quality in each broom, as the machines are programmed to tuft bristles with incredible precision.

One of the key advantages of broom tufting machines is their ability to accommodate various kinds of bristles, from natural fibers like corn husks and straw to synthetic materials like nylon and polypropylene. This versatility allows manufacturers to create brooms that suit a wide range of applications, from sweeping up debris on construction sites to cleaning delicate surfaces in homes.

Furthermore, broom tufting machines have also improved the ergonomics of the manufacturing process. By automating the tufting process, workers no longer have to manually insert bristles into broom heads, reducing the strain on their hands and wrists. This has not only improved the safety and comfort of workers but has also increased their overall productivity.

The efficiency and precision of broom tufting machines have also had a positive impact on the overall quality of brooms being produced. By removing the human error factor from the tufting process, manufacturers can ensure that each broom meets their exact specifications. This has led to a decrease in defects and customer complaints, ultimately enhancing the reputation of the brand.

In addition to the improvements in production output and quality, broom tufting machines have also helped manufacturers reduce their production costs. By automating the tufting process, companies can save on labor costs and produce brooms at a faster rate. This cost-saving benefit has allowed manufacturers to invest in new technologies and expand their product lines, ultimately leading to increased profitability.

Overall, the innovation of broom tufting machines has had a transformative effect on the traditional broom manufacturing industry. By increasing efficiency, precision, and quality while reducing production costs, these machines have revolutionized the way brooms are made. As technology continues to advance, it is likely that broom tufting machines will continue to play a crucial role in the evolution of the industry, driving further improvements in manufacturing techniques and product innovation.

Incorporating Technology for Enhanced Efficiency

The manufacturing industry has seen significant advancements over the years, with technology playing a crucial role in increasing efficiency and precision in various processes. One such innovation in the manufacturing sector is the development of broom tufting machines. These machines have revolutionized the production of brooms, brushes, and other cleaning tools, offering enhanced efficiency and precision like never before.

Broom tufting machines are specialized equipment designed to automate the process of attaching bristles to the broom base. Traditionally, this process was done manually, requiring skilled labor and a significant amount of time and effort. However, with the introduction of tufting machines, manufacturers can now produce brooms at a much faster pace and with greater consistency in quality.

One of the key features of broom tufting machines is their ability to incorporate advanced technology for enhanced efficiency. These machines are equipped with precision-controlled mechanisms that ensure accurate placement of bristles on the broom base. This level of precision is crucial in achieving consistent quality in the final product, which is essential for maintaining customer satisfaction and loyalty.

Furthermore, broom tufting machines are designed to be highly customizable, allowing manufacturers to adapt the machines to their specific production needs. This flexibility enables companies to produce a wide range of broom designs, sizes, and materials, catering to diverse market demands. With the use of cutting-edge technology, manufacturers can easily adjust settings on the tufting machines to achieve the desired results, making the production process more efficient and cost-effective.

In addition to efficiency and precision, broom tufting machines also offer other benefits that contribute to the overall productivity of the manufacturing process. For example, these machines are designed to be user-friendly, with intuitive interfaces that make operation easy and straightforward. This reduces the need for extensive training for machine operators, saving time and resources for manufacturers.

Moreover, broom tufting machines are equipped with safety features to ensure the well-being of workers in the manufacturing facility. With automated processes and built-in safety mechanisms, the risk of accidents and injuries is significantly reduced, creating a safer work environment for employees.

Overall, the innovation of broom tufting machines has transformed the manufacturing industry, offering enhanced efficiency, precision, and productivity in the production of brooms and other cleaning tools. By incorporating advanced technology into these machines, manufacturers can streamline their operations, reduce production costs, and improve the quality of their products. As technology continues to evolve, the future of broom tufting machines looks promising, with further advancements expected to drive even greater efficiency and innovation in manufacturing processes.

The Role of Automation in Broom Tufting Machines

Broom tufting machines have undergone a significant innovation with the incorporation of automation, revolutionizing the manufacturing process by enhancing efficiency and precision. The technological advancements in these machines have transformed the way brooms are produced, streamlining the entire manufacturing process and ensuring high-quality end products.

Automation plays a crucial role in broom tufting machines by replacing manual labor with sophisticated robotic systems that can perform tasks with unmatched accuracy and speed. This has resulted in increased productivity and reduced production costs, making broom manufacturing more cost-effective and sustainable.

One of the key benefits of automation in broom tufting machines is the improved precision in tufting. Automated systems can precisely control the tufting process, ensuring that each broom is made with consistent tufting patterns and density. This level of precision is crucial in ensuring the quality of brooms and meeting the exact specifications of customers.

Furthermore, automation has enabled manufacturers to produce brooms in large quantities without compromising on quality. Broom tufting machines can now operate continuously for long hours, resulting in higher production output and faster turnaround times. This is particularly beneficial for meeting the demands of the market and fulfilling bulk orders in a timely manner.

Another advantage of automation in broom tufting machines is the reduction of human errors. By automating repetitive tasks, the chances of errors in production are significantly minimized, leading to a more reliable manufacturing process and superior quality brooms. This guarantees customer satisfaction and enhances the reputation of the brand in the market.

In addition to efficiency and precision, automation in broom tufting machines also brings about cost savings for manufacturers. With reduced labor costs and increased productivity, manufacturers can optimize their production processes and improve their bottom line. This allows them to stay competitive in the market and invest in further innovations to enhance their manufacturing capabilities.

Overall, the incorporation of automation in broom tufting machines has revolutionized the broom manufacturing industry, making it more efficient, precise, and cost-effective. This technological advancement has paved the way for the production of high-quality brooms in large quantities, meeting the evolving demands of the market and driving the growth of the industry. As manufacturers continue to embrace automation in their production processes, the future of broom manufacturing looks promising, with endless possibilities for innovation and improvement.

Advantages of Precision and Consistency in Production

In today's fast-paced world of manufacturing, precision and consistency are key components to ensuring efficiency and quality in production processes. The innovation of broom tufting machines has revolutionized the way brooms are manufactured, providing a higher level of precision and consistency than ever before.

Broom tufting machines are specialized pieces of equipment designed to automate the process of tufting bristles onto broom heads. This automation not only increases the speed of production but also ensures that each broom is consistently and evenly tufted, resulting in a higher-quality finished product.

One of the primary advantages of using a broom tufting machine is the precision it offers in the production process. These machines are equipped with advanced technology that allows for precise control over the placement and density of the tufted bristles. This level of precision helps to eliminate inconsistencies in the finished product, resulting in a more uniform and professional-looking broom.

Consistency is another key advantage of using a broom tufting machine. By automating the tufting process, manufacturers can guarantee that each broom is tufted in the exact same manner, ensuring a consistent level of quality across all products. This consistency not only improves the overall appearance of the brooms but also enhances their functionality and durability.

In addition to precision and consistency, broom tufting machines also offer a significant increase in efficiency. These machines are capable of producing brooms at a much faster rate than traditional hand-tufting methods, allowing manufacturers to meet growing market demands with ease. This increased efficiency not only saves time but also reduces the overall cost of production, making broom tufting machines a cost-effective investment for manufacturers.

Overall, the innovation of broom tufting machines has had a profound impact on the manufacturing industry, providing a level of precision, consistency, and efficiency that was previously unattainable. By embracing this technology, manufacturers can streamline their production processes, improve the quality of their products, and stay ahead of the competition in today's fast-paced market.

In conclusion, the advantages of precision and consistency in production made possible by broom tufting machines cannot be overstated. By harnessing the power of automation and advanced technology, manufacturers can achieve higher levels of quality and efficiency in the manufacturing of brooms, ultimately leading to greater success in the marketplace.

Future Innovations in Broom Tufting Machine Design

The future of broom tufting machines is looking brighter than ever, with innovative designs that are revolutionizing the manufacturing process. Efficiency and precision are at the forefront of these advancements, allowing manufacturers to produce high-quality brooms at a faster rate than ever before.

One of the key innovations in broom tufting machine design is the incorporation of advanced technology, such as robotics and artificial intelligence. These technologies allow for greater control and accuracy in the tufting process, resulting in brooms that are uniform in size and shape. This not only improves the overall quality of the brooms but also reduces waste and increases productivity.

Another important aspect of future broom tufting machine design is sustainability. Manufacturers are increasingly looking for ways to reduce their environmental impact, and broom tufting machines are no exception. New designs are incorporating energy-efficient technologies and using sustainable materials, such as recycled plastics, to create brooms that are not only durable but also eco-friendly.

Furthermore, the future of broom tufting machines is focused on customization. With consumer preferences constantly changing, manufacturers need to be able to adapt quickly to meet demand. New designs are allowing for more flexibility in tufting patterns and colors, allowing for a wider range of broom styles to be produced.

In addition to these advancements in technology and sustainability, the future of broom tufting machines also includes improvements in ergonomics and safety. Manufacturers are designing machines that are easier to operate and maintain, reducing the risk of injury to workers and improving overall efficiency.

Overall, the future of broom tufting machines is promising, with innovations that are improving efficiency, precision, sustainability, and safety. As manufacturers continue to invest in research and development, we can expect to see even more exciting advancements in broom tufting machine design in the years to come.

Conclusion

In conclusion, the innovation of broom tufting machines has revolutionized the manufacturing industry by greatly improving efficiency and precision. These advanced machines have streamlined the production process, allowing for higher output and lower costs. With the ability to customize tufting patterns and designs, manufacturers can now create a wider range of high-quality brooms for various purposes. The future of broom manufacturing looks bright with the continued advancement of tufting technology, paving the way for even greater innovations in the industry. Overall, the implementation of broom tufting machines has proven to be a game-changer in the world of manufacturing.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019