Broom Tufting Machine: Revolutionizing The Production Of Cleaning Tools

Have you ever wondered how those perfectly aligned bristles on your broom or brush are made? Enter the broom tufting machine - the game-changing technology revolutionizing the production of cleaning tools. In this article, we delve into the fascinating world of tufting machines and uncover how they are transforming the way cleaning tools are made. Join us as we explore the innovative processes behind this essential tool-making technology.

- Introduction to Broom Tufting Machines

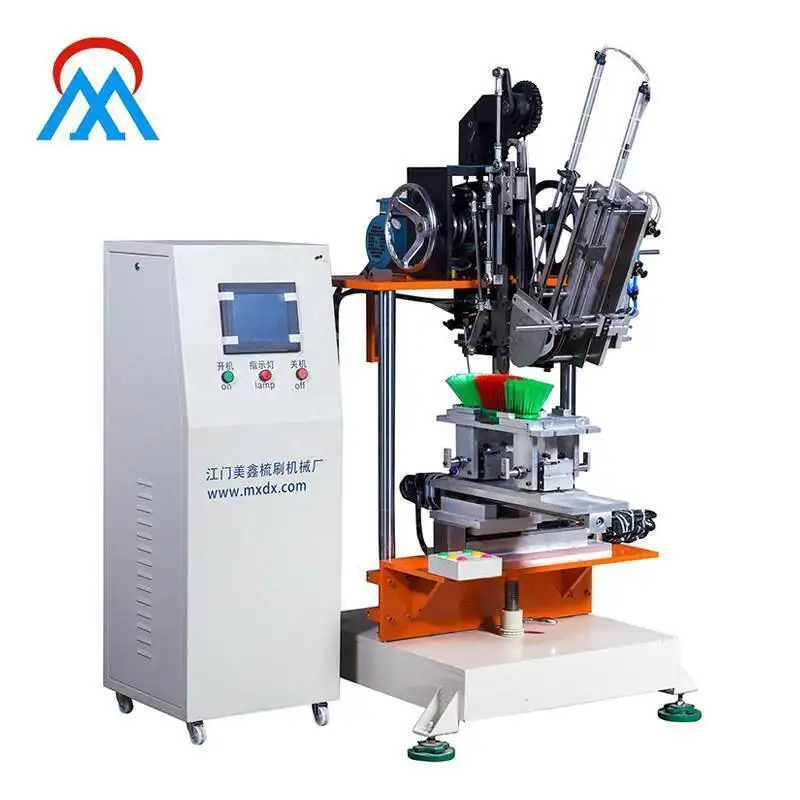

Broom tufting machines have revolutionized the production of cleaning tools, making the process more efficient and cost-effective. These machines are designed to automate the process of creating broom tufts, which are the individual strands of bristles that make up a broom. In this article, we will provide an introduction to broom tufting machines, exploring their key features and benefits.

One of the main advantages of broom tufting machines is their ability to produce brooms at a much faster rate than traditional hand tufting methods. These machines are equipped with multiple needles that can simultaneously insert bristles into a broom block, allowing for a rapid production process. This increased efficiency not only saves time but also reduces labor costs, making broom production more economically viable.

Another key feature of broom tufting machines is their versatility. These machines can be programmed to create different types of broom tufts, allowing manufacturers to produce a wide range of cleaning tools to meet various consumer needs. Whether it’s a stiff-bristled broom for outdoor use or a soft-bristled broom for indoor cleaning, broom tufting machines can accommodate a variety of specifications.

In addition to speed and versatility, broom tufting machines also ensure consistency in the quality of the final product. By automating the tufting process, these machines eliminate the potential for human error, resulting in evenly spaced and securely attached bristles. This consistency not only improves the overall aesthetics of the broom but also enhances its performance and durability.

Furthermore, broom tufting machines are also environmentally friendly. By reducing the amount of manual labor required for broom production, these machines help to lower carbon emissions and minimize waste. Additionally, the precise tufting process ensures that the bristles are securely attached to the broom block, reducing the likelihood of shedding and prolonging the lifespan of the broom.

Overall, broom tufting machines have significantly transformed the production of cleaning tools, making it more efficient, cost-effective, and sustainable. With their ability to automate the tufting process, these machines offer numerous benefits to manufacturers, from increased production speed and versatility to improved quality and consistency. As the demand for high-quality cleaning tools continues to grow, broom tufting machines are poised to play a key role in meeting consumer needs and driving innovation in the industry.

- The Impact of Broom Tufting Machines on Cleaning Tool Production

The cleaning industry has seen a significant transformation with the introduction of broom tufting machines. These innovative machines have revolutionized the production of cleaning tools, specifically brooms, by streamlining the manufacturing process and improving efficiency. In this article, we will explore the impact of broom tufting machines on cleaning tool production.

Broom tufting machines have completely changed the way brooms are manufactured. Traditionally, brooms were made by hand, a time-consuming and labor-intensive process. With the advent of broom tufting machines, manufacturers can now produce brooms at a much faster rate and with greater precision. These machines use advanced technology to automatically insert and fasten bristles into broom heads, resulting in a consistent and high-quality product.

One of the key advantages of broom tufting machines is their ability to increase production output. By automating the tufting process, manufacturers can significantly ramp up their production capacity and meet increased demand for cleaning tools. This has enabled companies to expand their market reach and cater to a wider customer base.

In addition to boosting production efficiency, broom tufting machines have also improved the overall quality of cleaning tools. The automated process ensures that bristles are evenly distributed and securely fastened, resulting in durable and effective brooms. This has led to a higher level of customer satisfaction, as consumers can now rely on high-quality cleaning tools that are built to last.

Furthermore, broom tufting machines have enabled manufacturers to customize their products to meet specific customer requirements. These machines offer a high degree of flexibility, allowing for the production of brooms in various sizes, shapes, and materials. This level of customization has opened up new opportunities for innovation in the cleaning industry, as manufacturers can now tailor their products to suit different cleaning needs and preferences.

Overall, the introduction of broom tufting machines has had a profound impact on the production of cleaning tools. These machines have revolutionized the way brooms are manufactured, providing a faster, more efficient, and higher-quality production process. With increased production output, improved product quality, and greater customization options, broom tufting machines have paved the way for a new era of innovation in the cleaning industry.

- Features and Benefits of Using Broom Tufting Machines

Broom tufting machines have revolutionized the production of cleaning tools, offering a range of features and benefits that have made them indispensable in the manufacturing industry. These machines have greatly improved the efficiency, accuracy, and quality of producing brooms, brushes, and other cleaning tools. In this article, we will explore the various features and benefits of using broom tufting machines.

One of the key features of broom tufting machines is their ability to automate the tufting process. This eliminates the need for manual labor, reducing production costs and increasing efficiency. With a broom tufting machine, manufacturers can produce a large volume of cleaning tools in a shorter amount of time, meeting the demands of the market with ease.

Another important feature of broom tufting machines is their versatility. These machines can be programmed to create a wide variety of cleaning tools, from brooms and brushes to mops and dusters. This flexibility allows manufacturers to cater to different market needs and produce a diverse range of cleaning products.

In addition to automation and versatility, broom tufting machines also offer precision and consistency in production. These machines are equipped with advanced technology that ensures each tuft is placed accurately and securely, resulting in high-quality cleaning tools that meet industry standards. The consistency provided by broom tufting machines also helps manufacturers maintain a uniform product quality, enhancing their reputation in the market.

Furthermore, using broom tufting machines can lead to cost savings for manufacturers. By streamlining the production process and reducing the need for manual labor, these machines help lower production costs and increase profitability. Additionally, the efficiency of broom tufting machines allows manufacturers to meet tight deadlines and fulfill orders in a timely manner, further enhancing their competitiveness in the market.

Overall, broom tufting machines have revolutionized the production of cleaning tools, offering a wide range of features and benefits that have made them essential in the manufacturing industry. From automation and versatility to precision and cost savings, these machines have greatly improved the efficiency, accuracy, and quality of producing brooms, brushes, and other cleaning tools. Manufacturers who invest in broom tufting machines can expect increased productivity, reduced costs, and enhanced product quality, giving them a competitive edge in the market.

- Advancements in Technology for Broom Tufting Machines

The production of cleaning tools has been revolutionized by advancements in technology for broom tufting machines. Broom tufting machines are used in the manufacturing process of brooms, brushes, and other cleaning tools to produce evenly spaced bristles or filaments. These machines have greatly increased the efficiency and precision of the production process, leading to higher quality cleaning tools being produced at a faster rate.

One of the key advancements in technology for broom tufting machines is the incorporation of computerized controls. These controls allow for precise adjustments to be made to the machine's settings, such as the speed of the tufting process and the spacing between bristles. This level of control ensures that each broom or brush produced is of consistent quality, with no variation in the tufting pattern. Additionally, computerized controls allow for quick and easy setup of the machine for different types of cleaning tools, reducing downtime between production runs.

Another important advancement in technology for broom tufting machines is the use of robotic arms. These arms are able to automatically feed materials into the tufting machine, reducing the need for manual labor and increasing production output. The robotic arms are also able to perform tasks with a high level of precision, ensuring that each broom or brush produced is of the highest quality. Additionally, the use of robotic arms improves workplace safety by reducing the risk of injuries from repetitive tasks.

The materials used in the production of cleaning tools have also seen advancements due to technology for broom tufting machines. Synthetic fibers such as nylon and polyester have become increasingly popular for use in brooms and brushes, as they are durable and have excellent tufting properties. These materials are able to withstand frequent use and provide superior cleaning performance compared to traditional natural fibers such as bristle or horsehair.

In addition to advancements in technology, broom tufting machines have also become more environmentally friendly. Manufacturers are now utilizing recycled materials in the production of cleaning tools, reducing waste and promoting sustainability. The use of environmentally friendly materials combined with the increased efficiency of broom tufting machines has led to a reduction in the carbon footprint of the manufacturing process.

Overall, advancements in technology for broom tufting machines have revolutionized the production of cleaning tools. These machines have improved efficiency, precision, and quality in the manufacturing process, leading to higher quality cleaning tools being produced at a faster rate. With the incorporation of computerized controls, robotic arms, and environmentally friendly materials, broom tufting machines are at the forefront of innovation in the cleaning tool industry.

- Future Innovations in Broom Tufting Machine Design and Functionality

Broom tufting machines have long been a staple in the production of cleaning tools, but recent advancements in technology have opened up a world of possibilities for future innovations in their design and functionality. These machines play a crucial role in the manufacturing process of brooms, creating the tightly packed bristles that allow for efficient cleaning.

One of the key areas of improvement in broom tufting machine design is automation. Traditional tufting machines required manual operation, with workers feeding materials through the machine and adjusting settings by hand. However, new automated tufting machines are equipped with sensors and programmable controls that can adjust settings in real-time, resulting in more precise and consistent tufting. This automation not only increases efficiency but also reduces the risk of human error, leading to higher quality end products.

Another exciting development in broom tufting machine design is the incorporation of smart technology. Smart tufting machines are able to communicate with other machines in the production line, optimizing workflow and reducing downtime. In addition, these machines are equipped with sensors that can detect and correct issues in real-time, further improving efficiency and productivity. The integration of smart technology into broom tufting machines is revolutionizing the way cleaning tools are manufactured, making the process faster, more reliable, and more cost-effective.

In terms of functionality, the future of broom tufting machines lies in their versatility. Manufacturers are now developing machines that can produce a variety of different bristle styles, lengths, and densities with a single machine. This versatility allows for greater customization and flexibility in the production of cleaning tools, catering to a wide range of customer preferences and requirements. Additionally, advancements in material handling technology have enabled tufting machines to work with a wider range of materials, including recycled plastics and sustainable fibers, further reducing the environmental impact of manufacturing processes.

Overall, the future of broom tufting machine design and functionality is bright, with exciting innovations on the horizon. Automation, smart technology, and versatility are driving the next generation of tufting machines, making the production of cleaning tools faster, more efficient, and more sustainable. As manufacturers continue to push the boundaries of what is possible, we can expect to see even more revolutionary advancements in broom tufting machine technology in the years to come.

Conclusion

The introduction of the broom tufting machine has truly revolutionized the production of cleaning tools. Not only has it increased efficiency and productivity in the manufacturing process, but it has also opened up new possibilities for innovative designs and customization options. This groundbreaking technology has paved the way for creating high-quality brooms that meet the varying needs of consumers. As we look towards the future, the broom tufting machine will continue to play a pivotal role in shaping the cleaning tool industry, driving further advancements and improvements in the way brooms are made. It is clear that this revolutionary machine has set a new standard for the production of cleaning tools, and its impact will continue to be felt for years to come.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019