Manufacturer's Guide to Cost-Effective Broom Tufting Machines

In the dynamic world of broom manufacturing, where efficiency and cost-effectiveness are paramount, the adoption of advanced broom tufting machines has transformed the industry. These machines are not just tools but powerful allies that streamline production, ensuring high-quality output. In this guide, we delve into the key aspects of broom tufting machines, drawing from real-world examples to provide practical insights and strategic recommendations.

Introduction to Broom Tufting Machines

Imagine a manufacturer, Mister Brooms Inc., which decided to invest in a cost-effective broom tufting machine. Within a year, they not only saw significant improvements in production speed and quality but also a 25% reduction in operational costs. This success story underscores the importance of modern tufting machines in broom manufacturing.

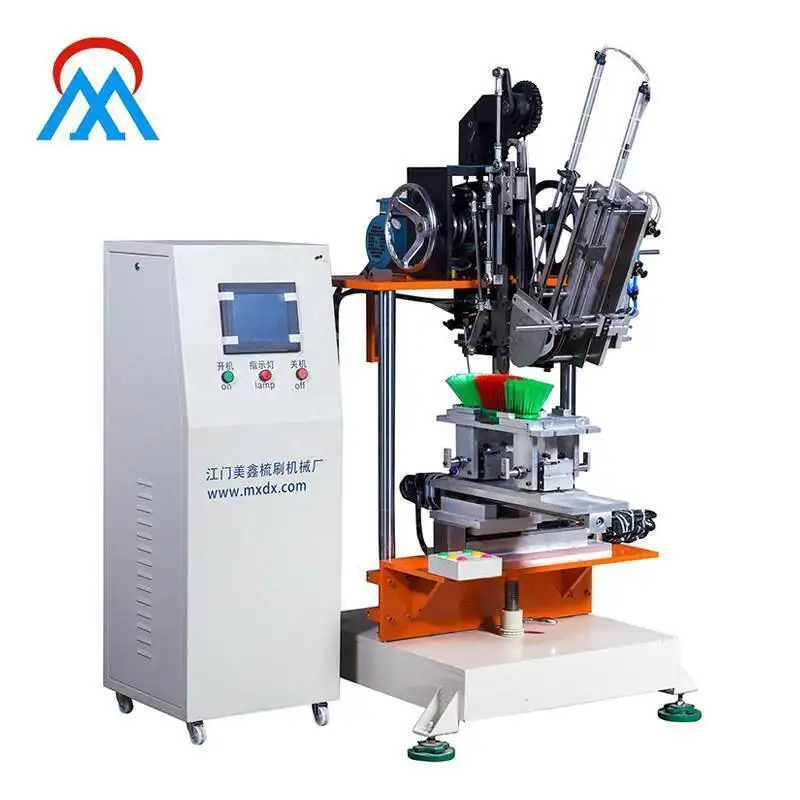

Broom tufting machines are specialized equipment designed to automate the process of inserting bristles into broom heads. They play a critical role in ensuring high precision, consistency, and speed, which manual processes simply cannot match. The advent of these machines has revolutionized broom production, making it more streamlined and cost-effective. For manufacturers seeking to stay competitive, investing in efficient tufting machines is crucial.

Understanding the Key Features of Broom Tufting Machines

Broom tufting machines are not just tools but sophisticated systems designed to enhance every aspect of broom manufacturing. Touchable screens offer a user-friendly interface, making operation intuitive and straightforward. Frequency variators allow for precise speed control, which is essential for maintaining consistency in the tufting process. Advanced servo motors ensure accurate bristle insertion, reducing the likelihood of errors and ensuring high-quality brooms.

To illustrate the impact, consider the example of SweeperCraft, a manufacturer that adopted a 5-axis tufting machine. By optimizing the speed and frequency settings, they achieved a 15% increase in production throughput and a significant reduction in material waste. This demonstrates how modern features translate into tangible cost savings and productivity gains.

Choosing the Right Broom Tufting Machine for Your Needs

Selecting the appropriate broom tufting machine can be a daunting task, given the variety available. The choice between 2-axis, 4-axis, and 5-axis machines depends on specific production needs. A 5-axis machine, as demonstrated by Mister Brooms Inc., simplifies programming and reduces setup time, making it ideal for complex designs.

When choosing a machine, consider the following critical factors:

- Cost: Ensure the machine fits within your budget and offers a good return on investment.

- Maintenance Requirements: Simple maintenance processes can significantly extend the machines lifespan and reduce downtime.

- Automation Capabilities: Higher levels of automation can reduce the need for manual labor and streamline operations.

For instance, a 4-axis machine might be sufficient for simple designs but can become cumbersome for intricate brooms. In contrast, a 5-axis machine, as recommended by SweeperCraft, offers versatile programming and ease of use, making it a more robust choice for diverse broom designs.

Strategies for Reducing Costs in Broom Manufacturing with Tufting Machines

Maximizing the potential of tufting machines requires strategic planning. Here are three key strategies:

1. Optimizing Machine Settings: Adjusting machine settings to reduce waste and improve efficiency can lead to significant cost savings. For example, optimizing speed and frequency settings can reduce material usage and minimize production time.

2. Regular Training for Operators: Providing regular training for operators ensures they are skilled in using the machine effectively. Training programs can cover everything from basic operation to troubleshooting, enhancing overall productivity.

3. Investing in Versatile Machines: Choosing machines that can handle multiple tasks can reduce the need for additional equipment and save operational costs.

For example, Mister Brooms Inc. found that training their operators in advanced features of their 5-axis machine led to a 10% increase in production rate and a 5% reduction in material costs.

Maintenance and Longevity: Ensuring Your Broom Tufting Machine Lasts

For instance, SweeperCraft implements a bi-weekly maintenance schedule that includes checking all moving parts, cleaning filters, and inspecting the electrical system. This routine helps them maintain peak performance and reduces unexpected downtime.

Innovations in Broom Tufting Machines

The future of broom tufting technology is promising, with emerging innovations that promise even greater efficiency and cost savings. Trends include the integration of artificial intelligence for enhanced automation and smart systems that enable remote monitoring and diagnostics.

For example, a machine equipped with AI technology can identify potential issues before they become critical, leading to preemptive maintenance and reduced repair costs. Manufacturers can stay ahead by embracing these advancements.

Maximizing Efficiency with the Right Broom Tufting Machine

In conclusion, the journey to cost-effective broom manufacturing begins with the right tufting machine. By understanding their features, choosing wisely, and employing strategic maintenance and operation techniques, manufacturers can achieve significant cost savings and efficiency gains. Staying informed about the latest trends ensures that businesses remain competitive in an ever-changing market.

Investing in the right broom tufting machine is not just a step towards improved productivity; it's a commitment to future-ready manufacturing. The benefits extend beyond immediate cost savings to include long-term operational efficiency and a competitive edge in the market.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019