Tackling Tough Twists: Mastering The Broom Tufting Machine

Welcome to a guide on mastering the art of working with the broom tufting machine. Tackling Tough Twists: Mastering the Broom Tufting Machine dives deep into the intricacies of using this powerful tool to create beautiful and durable brooms. Whether you're a seasoned professional looking to perfect your technique or a beginner eager to learn the ropes, this article is sure to provide you with valuable insights and tips to help you elevate your craft. Read on to uncover the secrets of mastering the broom tufting machine and take your broom making skills to the next level.

Understanding the Basics of Broom Tufting

Broom tufting is a specialized technique used in the manufacturing of brooms and brushes, and mastering the broom tufting machine is essential for achieving high-quality results. In this article, we will delve into the basics of broom tufting and provide a comprehensive guide on how to tackle tough twists when working with this machine.

Broom tufting involves attaching bristles or filaments to a handle or base to create a functional cleaning tool. The broom tufting machine is a key piece of equipment used in this process, and it plays a crucial role in creating a consistent and uniform product.

The broom tufting machine consists of a series of rotating drums or cylinders, each equipped with numerous holes or needles. These needles are used to guide the bristles or filaments through the holes in the base material, securing them in place.

Before operating the broom tufting machine, it is important to understand the different components and settings. This includes adjusting the speed of the drums, selecting the appropriate needle size, and setting the tension of the bristles or filaments. Proper calibration of these factors is essential for achieving the desired tufting pattern and density.

Tackling Tough Twists

One of the challenges that may arise when using the broom tufting machine is dealing with twists in the bristles or filaments. Twists occur when the material is not fed properly through the needles, resulting in uneven tufting and potential defects in the final product.

To tackle tough twists, it is important to ensure that the bristles or filaments are properly aligned before feeding them into the machine. This can be done by using a comb or brush to straighten out any kinks or tangles in the material.

In addition, adjusting the tension of the bristles or filaments can help prevent twists from occurring. Too much tension can cause the material to twist as it is pulled through the needles, while too little tension may result in loose or uneven tufting.

Regular maintenance of the broom tufting machine is also important for preventing twists and ensuring smooth operation. This includes cleaning the needles and drums regularly, checking for any worn or damaged parts, and lubricating moving components to reduce friction.

Mastering the broom tufting machine requires practice and patience, but with a thorough understanding of the basics and techniques for tackling tough twists, you can produce high-quality brooms and brushes with consistent tufting patterns. By following these guidelines and keeping your equipment in top condition, you can achieve professional results and streamline your production process.

Choosing the Right Machine for Your Needs

When it comes to tackling tough twists in the world of broom tufting, choosing the right machine for your needs is essential. Broom tufting machines are a crucial tool in the production of high-quality brooms, and selecting the correct machine can make all the difference in the efficiency and effectiveness of your operation.

One of the key factors to consider when choosing a broom tufting machine is the type of brooms you will be producing. Different machines are designed for different types of brooms, such as household brooms, industrial brooms, or specialty brooms like push brooms or street sweepers. Understanding the specific requirements of your production line will help you narrow down your options and find the perfect machine for your needs.

Another important consideration when selecting a broom tufting machine is the speed and capacity of the machine. If you have a high volume production line, you will need a machine that can keep up with the demands of your operation. Look for machines with high-speed capabilities and large tufting capacities to ensure that you can meet your production goals without any hiccups.

In addition to speed and capacity, it is also important to consider the overall performance and reliability of the machine. Look for machines from reputable manufacturers with a track record of producing high-quality equipment. You want a machine that is built to last and can handle the rigors of daily use in a production setting. Investing in a reliable machine will save you time and money in the long run by reducing downtime and maintenance costs.

When choosing a broom tufting machine, it is also important to consider the ease of use and maintenance of the machine. Look for machines with user-friendly controls and features that make operation simple and straightforward. Additionally, choose a machine that is easy to clean and maintain to ensure that it stays in top working condition for years to come.

Lastly, consider the cost of the machine and weigh it against the benefits it will provide for your operation. While it may be tempting to opt for a cheaper machine, investing in a high-quality machine upfront can save you money in the long term by providing reliable performance and reducing maintenance costs.

In conclusion, choosing the right broom tufting machine for your needs is a crucial decision that can have a significant impact on the success of your broom production operation. By considering factors such as the type of brooms you will be producing, the speed and capacity of the machine, its performance and reliability, ease of use and maintenance, and overall cost, you can find the perfect machine to tackle tough twists and master the art of broom tufting.

Mastering the Technique of Broom Tufting

Mastering the technique of broom tufting is essential for a successful operation of a broom tufting machine. Broom tufting is a process where nylon or other synthetic fibers are attached to a base material to create bristles for brooms, brushes, and other cleaning tools. The broom tufting machine automates this process, making it faster and more efficient than traditional hand tufting methods. In this article, we will discuss the key components of a broom tufting machine, the steps involved in mastering the technique, and some tips for tackling tough twists in the tufting process.

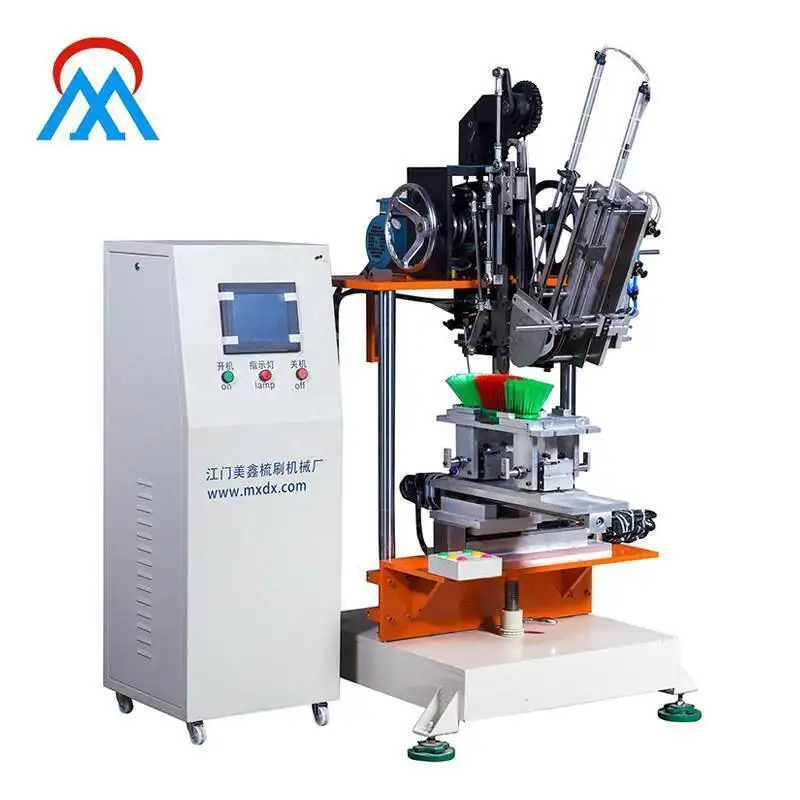

The key components of a broom tufting machine include a base material holder, a tufting head, a fiber feed system, and a cutting mechanism. The base material holder is where the material to be tufted is placed, while the tufting head is where the fibers are attached to the base material. The fiber feed system controls the flow of fibers to the tufting head, and the cutting mechanism trims the fibers to the desired length. Each component plays a crucial role in the tufting process, and mastering the technique involves understanding how each component works together to produce a high-quality end product.

To master the technique of broom tufting, one must first familiarize themselves with the controls and functions of the machine. This includes adjusting the speed and tension of the fiber feed system, setting the cutting mechanism to the correct length, and ensuring that the tufting head is properly aligned with the base material. Proper alignment is crucial for producing consistent tufting patterns and preventing uneven bristle lengths. Once the machine is set up correctly, the operator can begin tufting by feeding the fibers through the feed system and watching as the tufting head attaches them to the base material.

One of the challenges of mastering the technique of broom tufting is tackling tough twists in the fibers. Twists can occur when the fibers become tangled or bent out of shape, leading to uneven bristle lengths and a lower-quality end product. To tackle tough twists, operators can adjust the tension of the fiber feed system to ensure a smooth flow of fibers to the tufting head. Additionally, the cutting mechanism can be adjusted to trim any twisted fibers to the correct length, preventing them from affecting the overall tufting pattern.

In conclusion, mastering the technique of broom tufting is essential for achieving high-quality results with a broom tufting machine. By understanding the key components of the machine, familiarizing oneself with its controls and functions, and tackling tough twists in the fibers, operators can produce consistent tufting patterns and create durable and long-lasting cleaning tools. With practice and dedication, anyone can become proficient in the art of broom tufting and master the technique of using a broom tufting machine to its fullest potential.

Troubleshooting Common Issues with the Machine

For those in the textile industry, mastering the broom tufting machine is crucial in order to produce high-quality, consistent products. However, even the most experienced operators may encounter common issues with the machine that can disrupt production and affect the final product. In this article, we will address some of the most common problems that can arise when using a broom tufting machine and provide troubleshooting tips to help you overcome these obstacles.

One of the most common issues that operators may face when using a broom tufting machine is thread breakage. This can happen for a variety of reasons, including tension issues, worn or damaged needles, or a misaligned thread path. To troubleshoot this issue, start by checking the tension settings on the machine and adjusting them as needed. If the tension is too tight, it can put strain on the thread and cause breakage. Additionally, inspect the needles to ensure they are not bent or damaged, as this can also contribute to thread breakage. Finally, make sure that the thread path is correctly aligned and that there are no obstructions that could be causing the thread to break.

Another common issue that operators may encounter is uneven or inconsistent tufting. This can be caused by a number of factors, such as an improperly adjusted needle bar or feed roller, a dirty or damaged feed roller, or an issue with the feed mechanism. To troubleshoot this problem, start by checking the alignment of the needle bar and adjusting it as needed. Make sure that the feed roller is clean and free of debris, as buildup can affect the consistency of the tufting. Additionally, inspect the feed mechanism for any wear or damage that could be causing the issue.

In some cases, operators may find that the machine is jamming or skipping stitches during operation. This can be frustrating and may result in wasted time and materials. To troubleshoot this issue, start by checking the bobbin and shuttle area for any obstructions or tangled thread that could be causing the jamming. Clean out any debris and make sure that the shuttle is moving smoothly. Additionally, check the stitch length settings on the machine and adjust them as needed to prevent skipping stitches.

Finally, operators may encounter issues with the tension of the finished product, resulting in tufts that are either too loose or too tight. This can be caused by a variety of factors, such as improper tension settings on the machine, worn or damaged needles, or a misaligned stitch path. To troubleshoot this issue, start by adjusting the tension settings on the machine to achieve the desired result. Inspect the needles for any wear or damage and replace them if necessary. Finally, double-check the stitch path to ensure that it is correctly aligned and that there are no obstructions that could be affecting the tension of the finished product.

In conclusion, mastering the broom tufting machine requires attention to detail and a thorough understanding of the machine's operation. By familiarizing yourself with common issues and practicing troubleshooting techniques, you can overcome obstacles and produce high-quality products efficiently. Remember to regularly inspect and maintain your machine to prevent issues from arising in the first place. With these tips in mind, you can tackle tough twists and become a master of the broom tufting machine.

Taking Your Broom Tufting Skills to the Next Level

When it comes to the world of broom tufting, there is always room for improvement and growth. If you are looking to elevate your skills to the next level, then mastering the broom tufting machine is essential. In this comprehensive guide, we will delve into the strategies and techniques that will help you tackle tough twists and become an expert in using the broom tufting machine.

To start, it is important to fully understand the broom tufting machine and its components. The machine consists of a shaft that holds the broom handle, a needle bar that holds the needles, and a motor that controls the needle bar. The needles are used to tuft the broom fibers onto the handle, creating a sturdy and durable product.

One of the key components of mastering the broom tufting machine is learning how to handle tough twists. When tufting a broom, there may be twists or kinks in the fibers that can cause the needle to snag or break. To overcome this challenge, it is important to use the right needle size and angle, as well as adjust the machine's speed and tension settings. By making these adjustments, you can smoothly tuft even the toughest twists with ease.

Another important aspect of mastering the broom tufting machine is understanding the different types of fibers that can be used in the tufting process. Natural fibers such as straw, corn, or sorghum are commonly used for traditional brooms, while synthetic fibers like nylon or polyester offer durability and flexibility. By experimenting with different types of fibers, you can create unique and customized broom designs that will stand out from the rest.

In addition to mastering tough twists and exploring different fiber options, it is also crucial to perfect your tufting technique. This involves practicing proper needle placement, spacing, and angle to ensure that the fibers are securely tufted onto the handle. By paying attention to details and honing your skills, you can create high-quality brooms that are both functional and visually appealing.

As you continue to refine your broom tufting skills and master the machine, consider expanding your knowledge by exploring advanced techniques and experimenting with new materials. Whether you are tufting brooms for personal use or starting a business, taking your skills to the next level will set you apart in the world of broom making.

In conclusion, mastering the broom tufting machine is a rewarding journey that requires dedication, practice, and a passion for craftsmanship. By tackling tough twists, experimenting with different fibers, and perfecting your tufting technique, you can elevate your skills and create stunning brooms that will stand the test of time. So, roll up your sleeves, fire up the machine, and let your creativity soar as you embark on this exciting and fulfilling adventure.

Conclusion

In conclusion, mastering the broom tufting machine may seem like a daunting task at first, but with determination and practice, anyone can tackle the tough twists that come with it. By understanding the intricacies of the machine and perfecting the art of tufting, individuals can create high-quality brooms with ease. Remember, practice makes perfect, so keep experimenting and honing your skills to become a master at broom tufting. With dedication and perseverance, you'll be able to tackle any challenge that comes your way in the world of broom making.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019