Upgrade to a Plastic Broom Making Machine for Better Production

The evolution of broom production is a testament to the power of technology in reshaping industries. From handcrafted brooms made with natural materials to the sleek, durable plastic brooms of today, the journey has been marked by significant advancements. In this competitive market, the importance of efficiency and precision in manufacturing cannot be overstated. Modern broom making machines embody these principles, setting new standards for production.

Why Upgrade to a Plastic Broom Making Machine?

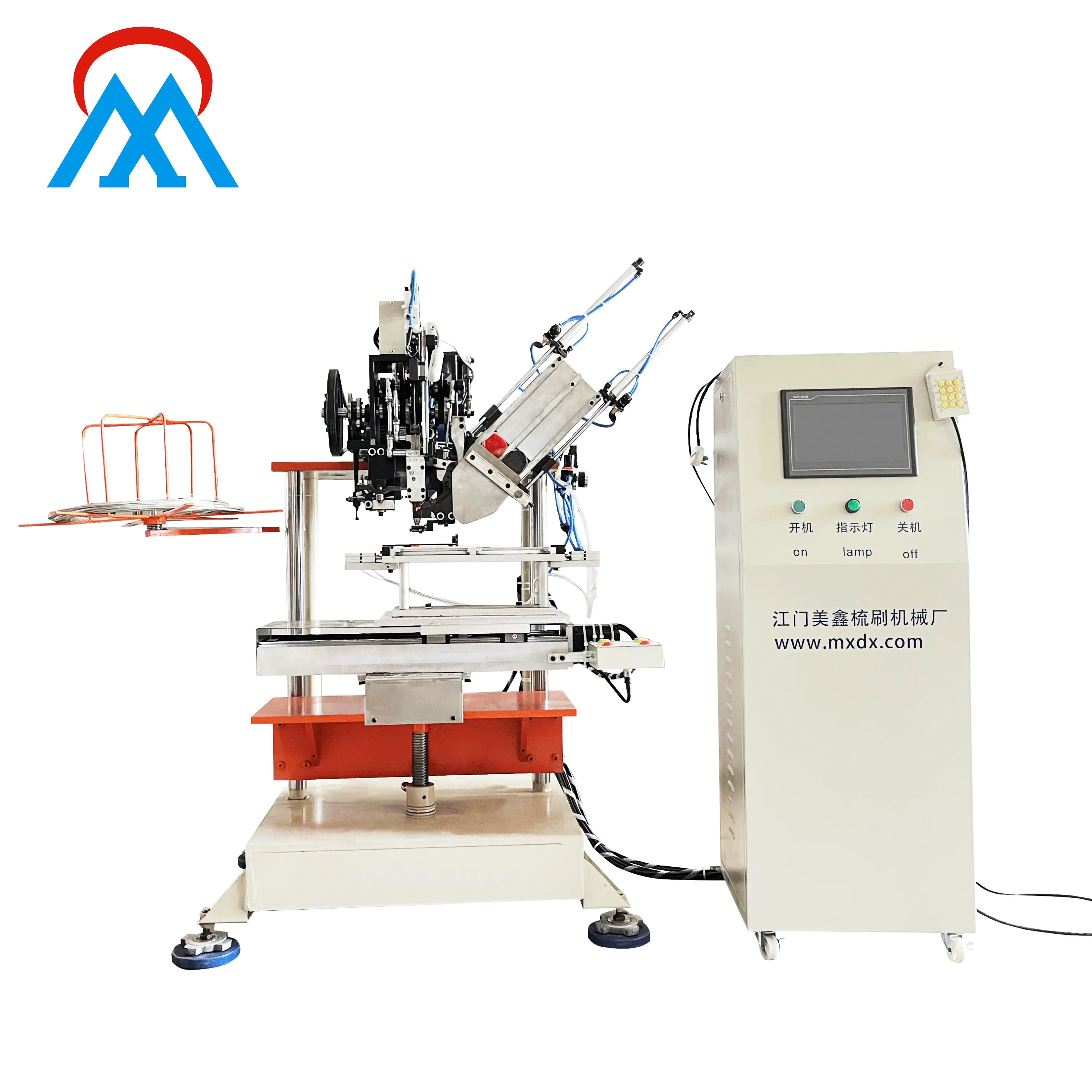

Plastic broom making machines are equipped with advanced features that redefine manufacturing standards. Automation allows for seamless integration of processes, from molding to bristle attachment, minimizing human error. Precision engineering ensures that each broom meets exact specifications, enhancing quality and consistency. These features not only streamline production but also elevate the overall product standard.

Economic Advantages of Modernizing Broom Production

The economic benefits of upgrading to a plastic broom making machine are substantial. With increased efficiency, manufacturers can achieve higher output with less waste, translating into significant cost savings. The reduction in labor costs and improved production capabilities result in higher profit margins. For businesses looking to expand their market presence, these machines offer a competitive edge by facilitating large-scale production.

Environmental Impact and Sustainability

In an era where sustainability is paramount, plastic broom making machines contribute positively to environmental goals. These machines are designed to optimize material usage, significantly reducing waste. Additionally, their energy-efficient operations lower overall energy consumption, supporting eco-friendly practices. By embracing modern technology, manufacturers can align themselves with sustainable business models that appeal to environmentally conscious consumers.

Case Study: Success Stories in the Industry

Consider the hypothetical example of BroomTech Industries, a mid-sized broom manufacturing company that upgraded to plastic broom making machines. Within a year, the company doubled its production capacity, reduced waste by 30%, and expanded its market reach internationally. This success was driven by the machine's ability to produce consistent, high-quality brooms at a fraction of the previous cost, showcasing the transformative impact of modernization.

Considerations for Investing in a Plastic Broom Making Machine

Before investing in a plastic broom making machine, manufacturers should consider several factors. The initial cost, while significant, must be weighed against long-term benefits such as scalability and operational efficiency. It's crucial to select a machine that aligns with specific business needs, considering factors like production volume and customization capabilities. Engaging with reputable suppliers and understanding machine specifications can guide a successful investment.

Embracing the Future of Broom Manufacturing

In conclusion, upgrading to a plastic broom making machine is a strategic move that promises substantial benefits. From enhanced production efficiency and quality to economic savings and sustainable practices, these machines are a game-changer for the broom manufacturing industry. As technology continues to advance, embracing these innovations will equip manufacturers with the tools needed to thrive in a competitive market. By adopting modern technology, manufacturers not only stay ahead of the curve but also position themselves for long-term success.

Ultimately, upgrading to a plastic broom making machine is the smart choice for modern manufacturers. Dont miss the opportunity to revolutionize your production process today!

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019