Examining the Differences in Broom Quality Between Automated and Manual Processes

Understanding Manual Broom Making: Artistry and Craft

Manual broom making is a time-honored tradition that demands skill and precision. Artisans carefully select natural materials like sorghum or corn husks, which provide both durability and natural charm. Each bristle is then meticulously tied to the broom handle, a process that requires a steady hand and a keen eye for detail. This handcrafted approach results in unique, one-of-a-kind brooms that not only perform their cleaning duties but also serve as a tangible connection to the past. The aesthetic appeal of these brooms is unmatched, as each piece carries the distinct mark of its creator.

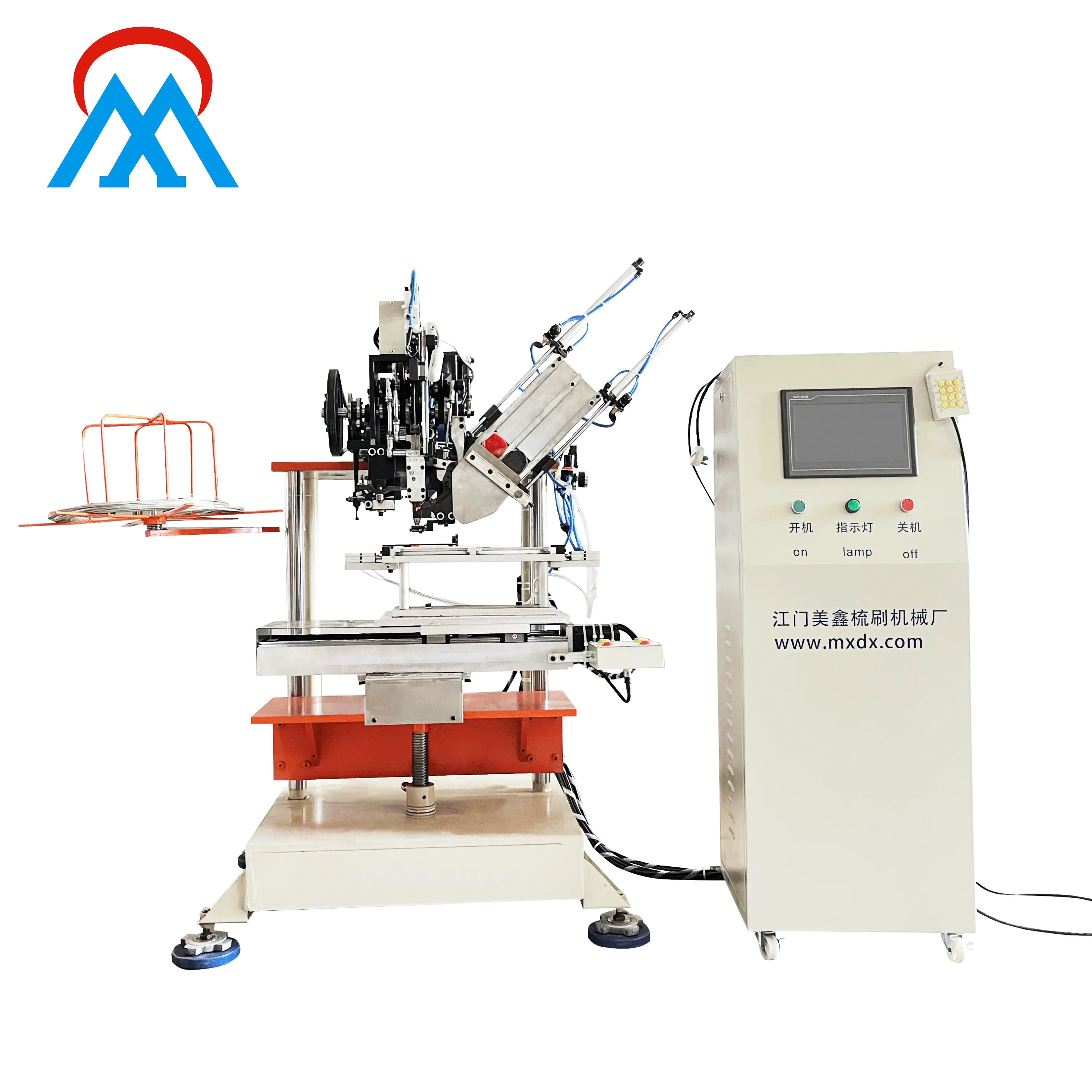

Automated Broom Production: Efficiency and Consistency

In contrast, automated broom production leverages modern technology to streamline the manufacturing process and produce brooms at an unprecedented rate. Plastic broom making machines can produce thousands of brooms in a single day, far exceeding the output of manual craftsmen. These machines ensure uniformity in every product, making sure that each broom is precisely crafted to the same standard. The benefits of automation are clear: increased productivity and cost-effectiveness, without compromising on basic quality. These brooms are designed for efficiency and reliability, making them a favorite among households and businesses that value consistency in their cleaning tools.

Comparative Analysis: Quality Differences Between Manual and Automated Brooms

When comparing the quality of brooms from manual and automated processes, several key factors come into play. One of the most notable differences is durability. Handmade brooms, while more labor-intensive, often outlast their machine-made counterparts due to the superior quality of natural materials and the meticulous construction. In terms of aesthetics, manual brooms offer a unique charm that appeals to consumers seeking authenticity and individuality. Automated brooms, on the other hand, provide consistent performance and ease of use, making them a practical choice for those who prioritize functionality over aesthetics. Consumer preferences often depend on these quality outcomes, with some valuing the bespoke nature of handmade brooms and others preferring the reliability of machine-made counterparts.

Successes and Challenges in Both Methods

Real-world examples highlight the successes and challenges of both manufacturing methods. Artisanal broom makers often struggle to maintain production speed and volume, making it difficult to keep up with the demands of modern businesses. Conversely, automated factories can achieve high output levels but must ensure that quality standards are maintained despite the high volume. However, both methods have their champions. Traditional workshops thrive on the loyal customer base drawn to the unique craftsmanship of their products, while large-scale manufacturers benefit from economies of scale and widespread distribution. This duality underscores the importance of catering to diverse consumer preferences.

The Role of Innovation in Broom Manufacturing

Innovation plays a pivotal role in the continuous evolution of broom manufacturing. Advances in plastic broom making machines have introduced features such as ergonomic designs and eco-friendly materials, enhancing both the functional and environmental aspects of these cleaning tools. Looking ahead, the industry anticipates further advancements, including smart brooms equipped with integrated sensors that optimize cleaning performance. These technological innovations promise to refine the broom-making process, ensuring that the future of broom production is both efficient and sustainable.

Balancing Tradition and Technology for Optimal Quality

The evolution of broom manufacturing represents a delicate balance between tradition and technology. While handmade brooms offer an irreplaceable touch of artistry and charm, automated processes provide unparalleled efficiency and consistency. Ultimately, the future of broom production lies in integrating the best of both worlds, allowing manufacturers to produce high-quality products that honor the past and embrace the future. By appreciating the strengths of each method, manufacturers can continue to sweep the industry forward with innovation and tradition hand in hand.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019