Optimal Plastic Broom Making Machine for Your Business

In the dynamic world of manufacturing, efficiency and productivity are the linchpins of success. The plastic broom making industry has witnessed a significant surge in demand due to the escalating need for efficient cleaning solutions in homes, offices, and commercial spaces. As businesses strive to meet this demand, choosing the right broom making machine becomes crucial. These machines offer a blend of automation and precision, transforming raw materials into high-quality brooms with minimal human intervention. Understanding the importance of this equipment can give your business a competitive edge.

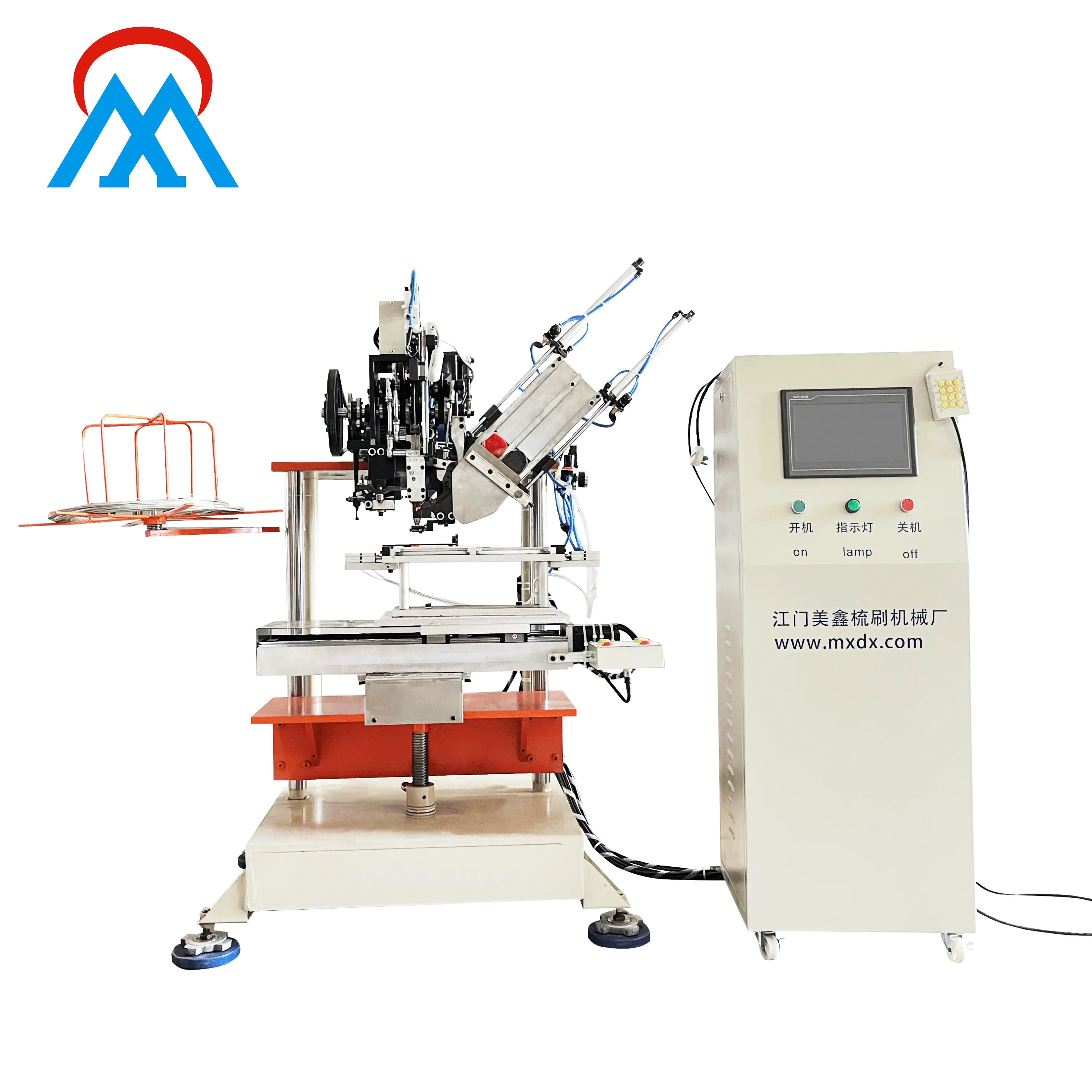

Introduction to Plastic Broom Making Machines

The plastic broom making industry has surged in recent years, driven by the growing need for efficient cleaning solutions in various settings. This trend has made it imperative for manufacturers to seek out advanced broom making machines. These machines streamline the production process, ensuring that raw materials are turned into high-quality brooms with minimal human effort. The benefits are clear: increased efficiency, improved product quality, and enhanced customer satisfaction.

Understanding the Key Features of Plastic Broom Making Machines

When evaluating plastic broom making machines, certain features are essential. These include automation capabilities, production speed, material compatibility, and energy efficiency.

Automation Capabilities

Automation plays a pivotal role in reducing labor costs and increasing production output. High-quality machines are equipped with advanced automation features, allowing for precise and consistent production. This translates to a streamlined workflow and enhanced productivity. Efficient machines ensure that the production process is not only faster but also more reliable.

Production Speed

Speed is another critical factor. Machines with high production speeds ensure quick turnaround times, meeting the demands of a fast-paced market. Faster production cycles also mean quicker returns on investment, making these machines a smart choice for businesses looking to scale up their operations. Effective machines can handle larger volumes of production with ease, reducing the risk of shortages and ensuring consistent supply.

Material Compatibility

Selecting a machine that can handle various plastic types is crucial. This versatility allows you to cater to diverse customer preferences and produce brooms that can withstand different environments and usage conditions. Whether its polystyrene, polyethylene, or any other material, the right machine can handle it all. Versatile machines ensure that you can meet the specific needs of your customers without limitations.

Energy Efficiency

Energy-efficient models not only lower operational costs but also contribute to environmental sustainability. These machines consume less energy, reducing both your utility bills and your carbon footprint. Investing in energy-efficient technology is not only cost-effective but also aligns with the growing trend towards eco-friendliness. Environmentally friendly machines are a key feature for businesses that value sustainability.

Evaluating Costs and Benefits: Is It Worth the Investment?

Purchasing and maintaining a plastic broom making machine is a significant investment. However, the potential for increased productivity, reduced labor expenses, and improved product quality make it a worthwhile investment.

Upfront Costs

High-quality machines come with a higher upfront cost. However, this investment is often justified by the long-term benefits. Durable machines from reputable manufacturers ensure consistent output and minimize downtime, driving long-term growth and profitability. Sustainable machines provide a solid foundation for your business's future success.

Long-Term Benefits

The long-term benefits of investing in a plastic broom making machine include increased production efficiency, reduced labor costs, and improved product quality. By streamlining your operations, you can meet market demands more effectively and gain a competitive edge. Effective machines ensure that your business remains agile and responsive to changing market needs.

Successful Implementation of Plastic Broom Making Machines

Several businesses have successfully integrated plastic broom making machines into their operations, yielding impressive results.

Case Study 1: Green Cleaning Supplies

Green Cleaning Supplies, a mid-sized cleaning supplies company, adopted automated broom making technology and saw a 50% increase in production efficiency. Their meticulous approach to employee training and regular maintenance schedules played a crucial role in their success. Efficient machines allowed them to handle larger volumes of production without compromising quality.

Case Study 2: Eco-Broom Innovations

Eco-Broom Innovations, a startup in the green cleaning industry, used a high-speed plastic broom making machine to quickly respond to market demands. This allowed them to expand their product line and meet increasing customer orders without compromising quality. Effective machines ensured that they could meet the fast-paced demands of the market seamlessly.

Comparative Analysis: Manual vs. Automated Plastic Broom Making

The decision between manual and automated broom making processes involves weighing various factors. Manual production allows for customization and lower initial costs but is labor-intensive and less efficient. Automated machines, on the other hand, offer speed, uniformity, and scalability, making them ideal for large-scale operations.

Customization vs. Speed

Manual production is highly customizable, allowing for precise adjustments to meet specific customer requirements. However, this comes at a higher cost in terms of labor and time. Automated machines, while offering less flexibility, achieve higher speeds and consistency, making them more suitable for mass production. Effective machines provide a balance between customization and efficiency.

Efficiency and Scale

Automated machines provide a boost in efficiency and scalability, enabling businesses to meet growing market demands. They can handle larger volumes of production with ease, reducing the risk of shortages and ensuring consistent supply. Scalable machines ensure that your business can grow without major disruptions.

Navigating Challenges and Solutions in Plastic Broom Manufacturing

Despite the advantages, the plastic broom manufacturing sector faces challenges such as fluctuating material costs, maintenance requirements, and market competition.

Material Costs

Fluctuating plastic material costs can impact your bottom line. To mitigate this, diversify your material suppliers to secure a steady supply at competitive prices. This can help absorb price fluctuations and ensure continuity in production. Cost-effective machines help maintain operational stability.

Maintenance Requirements

Regular maintenance is crucial to keep your machine running smoothly. Establish a maintenance schedule and invest in the necessary tools and spare parts. This proactive approach can minimize downtime and maximize machine performance. Reliability is key to delivering consistent results.

Market Competition

Staying competitive in a crowded market requires continuous innovation and quality improvement. Keep up with industry trends and customer feedback to refine your products and stay ahead of the competition. Innovative machines ensure that your business stays relevant and appealing to consumers.

Making the Right Choice for Your Business

Selecting the optimal plastic broom making machine is a critical decision that can significantly impact your business performance. By understanding the key features, evaluating costs and benefits, and learning from successful implementations, you can make informed choices that enhance productivity and profitability. Investing in the right equipment will position your business for success in the dynamic plastic broom manufacturing industry, empowering you to meet growing market demands with efficiency and precision. Overall, the right machine not only improves production but also elevates the quality and sustainability of your brooms, setting you apart in the competitive market of cleaning supplies.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019