Plastic Broom Making Machine vs. Traditional Methods

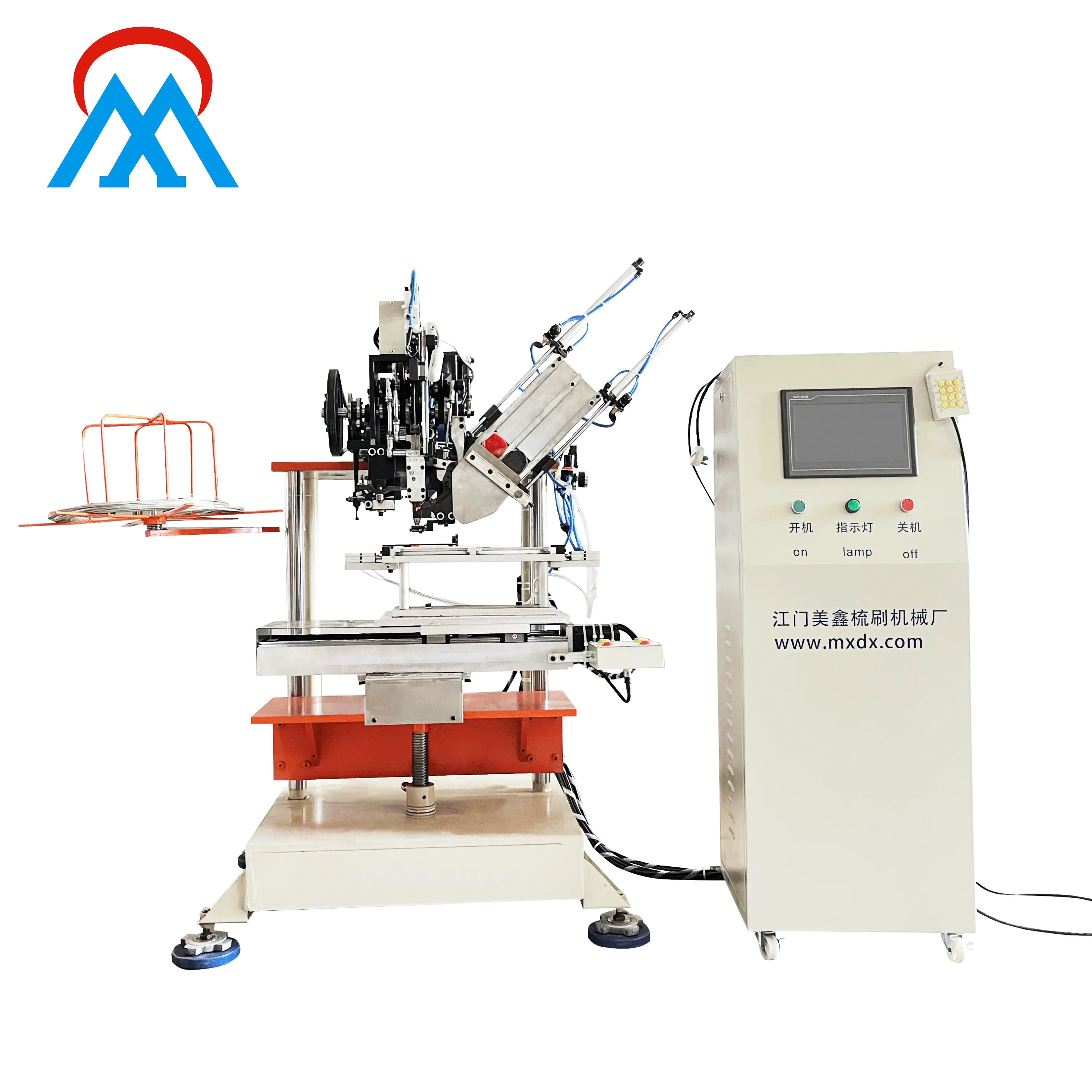

The plastic broom making machine has transformed the production process by automating several labor-intensive tasks. Equipped with advanced components, it extrudes plastic into broom shapes, attaches handles, and trims bristles with precision. This machine not only enhances efficiency but also reduces material waste, making it a sustainable choice for manufacturers. Unlike traditional methods, which rely on manual labor, the plastic machine significantly reduces production time and minimizes environmental impact. The machine's precision and speed ensure that brooms are made with minimal waste, which is crucial for sustainability. Additionally, the machine's durability and low maintenance requirements further contribute to its cost-effectiveness and longevity.

Cost-Benefit Analysis: Which Method Is More Advantageous?

A plastic broom making machine offers significant cost savings in the long run. While the initial investment is substantial, it offsets the costs of materials and labor over time. The machine's efficiency reduces waste, lowering operational costs. Traditional methods, on the other hand, are labor-heavy, leading to higher expenses and less productivity. Energy efficiency is another advantage of the plastic machine. It consumes less energy compared to traditional methods, contributing to a smaller carbon footprint. The machine's automation also allows for continuous production, increasing output and reducing downtime. This makes the plastic broom making machine a more attractive option for manufacturers looking to reduce their environmental impact while improving efficiency.

Environmental Impact: The Plastic Machine's Role

The plastic broom making machine plays a crucial role in reducing environmental impact. By minimizing single-use plastic waste, it contributes to a circular economy. Its energy efficiency and reduced carbon emissions make it a sustainable alternative to traditional methods. As the demand for eco-friendly products grows, manufacturers are pressured to adopt technologies that align with global sustainability standards. This shift towards sustainable manufacturing not only benefits the environment but also helps companies meet regulatory requirements and consumer preferences.

Worker Satisfaction: A Human Side of Efficiency

Now, let's consider the impact of the plastic broom making machine on worker satisfaction. Adopting a plastic broom making machine may disrupt traditional work roles, such as handling brooms manually. However, the machine enhances productivity, allowing workers to focus on higher-value tasks. While automation may reduce human interaction, it also creates opportunities for new roles, such as machine maintenance and quality control, enriching the work experience. For example, a company that moved to a plastic broom making machine noted a significant reduction in waste and a boost in overall productivity, while workers were trained to take on new roles in maintenance and quality control.

The Future of Broom-Making: Integration of Technology and Sustainability

Looking to the future, the broom-making industry will continue to integrate advanced technologies and sustainable practices. Emerging innovations, such as AI-driven quality control systems, promise to further enhance efficiency and product consistency. Embracing renewable energy sources and circular economy principles will align production with environmental goals. For instance, a forward-thinking manufacturer is exploring solar power to reduce its energy footprint and looking into recycling programs for materials.

Embracing the Plastic Broom Making Machine

By adopting the plastic broom making machine, manufacturers can position themselves as leaders in eco-friendly production and gain a competitive edge in the market. As the industry evolves, sustainability will remain a key focus, ensuring that broom-making continues to thrive in a greener, more efficient world.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019