Choose the Best Plastic Broom Making Machine

In todays industrial landscape, the selection of a high-quality plastic broom making machine is crucial for productivity and efficiency. These machines are vital for producing durable and effective plastic brooms used in cleaning and maintenance industries. With a variety of options available, choosing the best one can be challenging. This guide will walk you through the essential features to look for, as well as practical tips to help you make the best choice.

Introduction

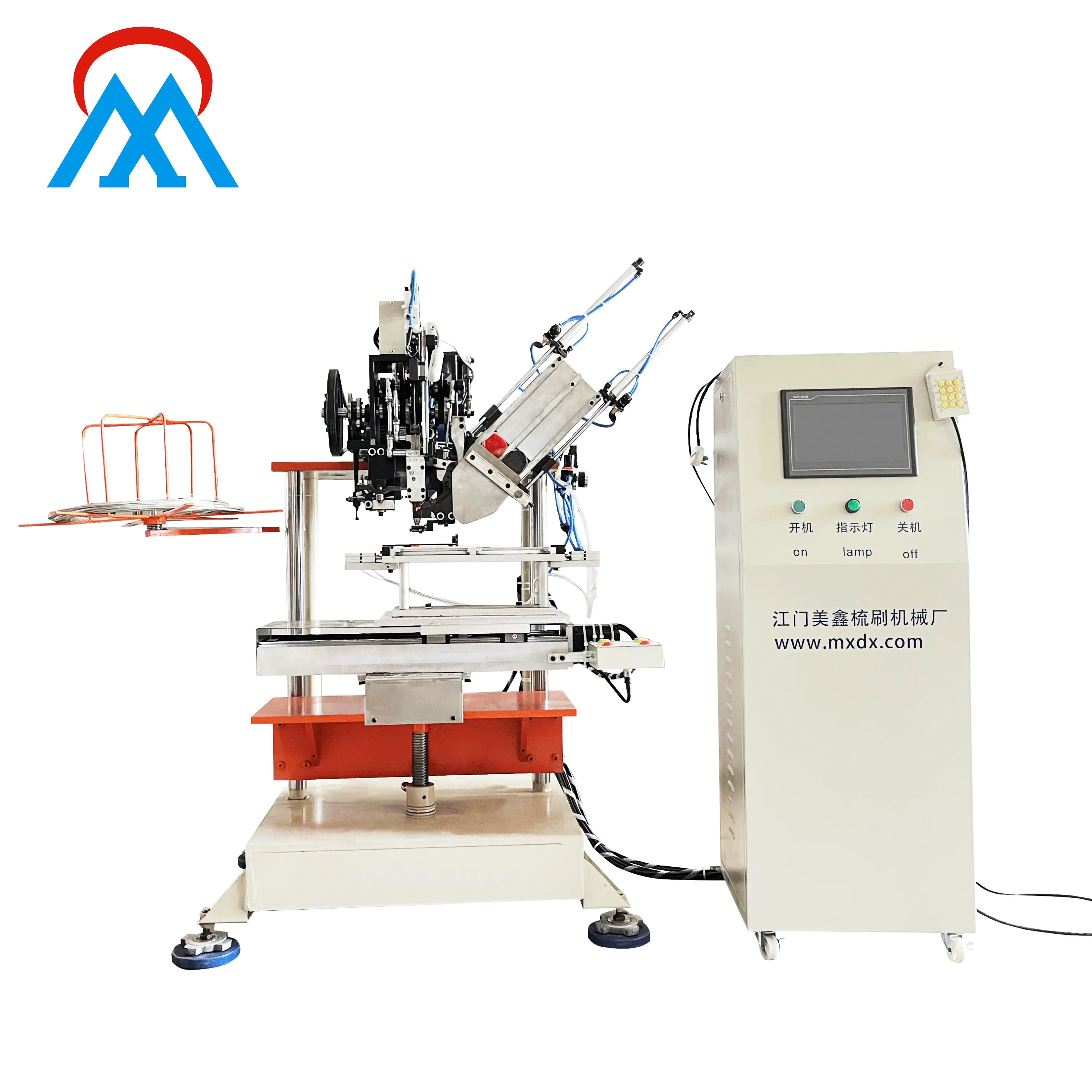

Imagine the efficiency and precision of a plastic broom making machinehow it transforms raw materials into high-quality brooms that meet the demands of modern industries. Selecting the right plastic broom making machine is not just about getting a machine that does the job; its about finding one that meets your specific needs, enhances productivity, and ensures long-term efficiency. Whether youre a small-scale entrepreneur or a large manufacturing facility, the right machine can significantly impact your operations. This guide will provide you with a comprehensive understanding of the key features and benefits, as well as practical buying tips.

The Importance of Features in a Plastic Broom Making Machine

The functionality and efficiency of a plastic broom making machine depend on several critical features. Here are some of the most essential ones to consider:

Operational Efficiency

- Speed and Capacity: A machines speed and capacity determine its production rate and efficiency. Look for machines that can handle your required volume without compromising on quality. For example, a machine with a high-speed capacity of 500 brooms per hour can significantly boost your production capacity.

- Automation: Modern plastic broom making machines often come with automation features, such as automatic feeding, level control, and speed adjustment. These features can improve productivity by reducing manual intervention. For instance, automated feeding can ensure consistent material intake, leading to uniform broom quality.

Durability and Material Quality

- Material Quality: The quality of materials used in the machine, such as the motor, bearings, and lubricants, directly impacts its longevity and performance. High-quality components reduce wear and tear and ensure smooth operation. Materials made from durable stainless steel or durable plastics are less prone to wear and tear and can withstand harsh operating conditions.

- Food Grade Lubricants: Many plastic broom making machines use food-grade lubricants, which are safe for both the machine and the environment. These lubricants minimize contamination risks, ensuring hygiene standards are met.

Ergonomics and User Experience

- Ergonomic Design for Optimal Comfort: An ergonomic design ensures that the machine is comfortable to operate, reducing the risk of fatigue and strain. Look for machines with intuitive controls, easy-to-reach buttons, and a balanced weight distribution. For instance, a machine with a handle that is easy to grip and adjust can significantly reduce user fatigue during long shifts.

- Adjustability and Customization: Many plastic broom making machines come with adjustable controls and customization options. These features allow users to tailor the machine to their specific needs, improving efficiency and productivity. For example, adjustable speed settings can help balance production speed with material quality.

Understanding the Materials and Construction of the Machine

The materials and construction of a plastic broom making machine play a significant role in its performance and durability. Here are some key considerations:

Advanced Materials

- Stainless Steel Components: Stainless steel components are durable and resistant to corrosion, making them ideal for industrial use. Machines with stainless steel parts are less prone to wear and tear and can operate more efficiently in industrial settings.

- Durable Plastics: Durable plastics are resistant to wear and tear and can withstand harsh operating conditions. For example, a machine with a frame made of high-quality steel can handle heavy productions without degrading.

Construction Techniques

- Hanging Body Design: A hanging body design allows for easy cleaning and maintenance, reducing the risk of contamination and minimizing waste. This design is essential for maintaining hygiene standards in industrial settings.

- Modular Design: Modular design features can enhance flexibility and maintenance. Components that can be easily replaced or upgraded extend the machines lifespan and reduce downtime.

Energy Efficiency

- Water-Cooled Motors: Water-cooled motors are more efficient and produce less heat compared to traditional air-cooled motors. This feature is crucial for machines that run for extended periods, as it ensures consistent performance and reduces maintenance needs.

Budget Considerations for Plastic Broom Making Machines

Budgeting is an essential aspect of purchasing a plastic broom making machine. Here are some tips to help you make the best choice within your budget:

Affordability vs. Quality

- Durable Machines: While its tempting to go for the most expensive machine, its important to balance affordability with quality. High-quality machines may cost more initially but often save you money in the long run through reduced maintenance costs and higher production efficiency. For example, a durable machine with proven longevity can save you money on replacements and repairs.

- Long-Term Savings: When investing in a plastic broom making machine, consider the long-term costs, including maintenance, repairs, and energy consumption. A machine that may seem expensive initially could be a more cost-effective long-term investment. For example, a machine with low energy consumption can save you money on electricity bills over time.

Safety Features and Compliance

Safety is a top priority when selecting a plastic broom making machine. Here are some key safety features to look for:

Safety Precautions in Operation

- Clear Instructions and Safety Precautions: All machines should come with clear instructions and safety precautions to ensure safe operation. Familiarize yourself with these guidelines before starting the production process. For example, a machine with a warning label on the control panel can remind users to wear appropriate protective gear.

- Compliance with Industrial Standards: Ensure that the machine complies with relevant safety and quality standards. Compliance with industry regulations not only protects your workers but also ensures that the machine meets environmental and safety requirements. For example, a machine that complies with OSHA standards can provide peace of mind during production.

Final Tips for Choosing the Best Plastic Broom Making Machine

Choosing the best plastic broom making machine is a crucial decision that can significantly impact your production efficiency and cost savings. Here are some final tips to help you make the best choice:

- Research and Compare: Dont settle for the first machine you find. Take the time to research and compare different models to find the best fit for your requirements.

- Read Reviews: Look for reviews and testimonials from other users to get insights into the machines performance and reliability.

- Invest in Maintenance: Regular maintenance and inspections can extend the lifespan of the machine and ensure optimal performance. For example, a well-maintained machine can reduce downtime and improve overall efficiency.

Conclusion

Imagine the efficiency and precision of a plastic broom making machinehow it transforms raw materials into high-quality brooms that meet the demands of modern industries. Investing in the right plastic broom making machine is not just about getting a machine that does the job; its about unlocking efficiency, productivity, and long-term success for your business. With the features and considerations outlined in this guide, you can make an informed decision that sets your operations apart. How will you choose your next plastic broom making machine to boost your operations?

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019