Company Advantages1. MX machinery Drilling And Tufting Machine is constantly inspected by the QC team. It is assessed in terms of the spectral properties of the light sources, filters, and sensors. "Meixin

brush machine is of best sophisticated design

2. Thanks to its maintenance and easy control, the product can significantly reduce the need for labor, which will directly cut down labor costs. Ease of installation is one of the most characteristics of Meixin products

3. The product has the advantage of good heat dissipation. Its latest cooling system enables adequate airflow, which makes it not accumulate too much heat. Meixin products have been approved several International Certification

4. The product features remarkable loading strength. Its materials, mainly metals, have desired mechanical properties to endure heavy-duty use. Meixin's products cover various sizes of machines and are popular among customers with computer screen display

5. The product is remarkable for its sealing performance. It will be tested under static pressure to check whether there is a leakage phenomenon. Meixin can make the machine according to customers' requirements

special features:

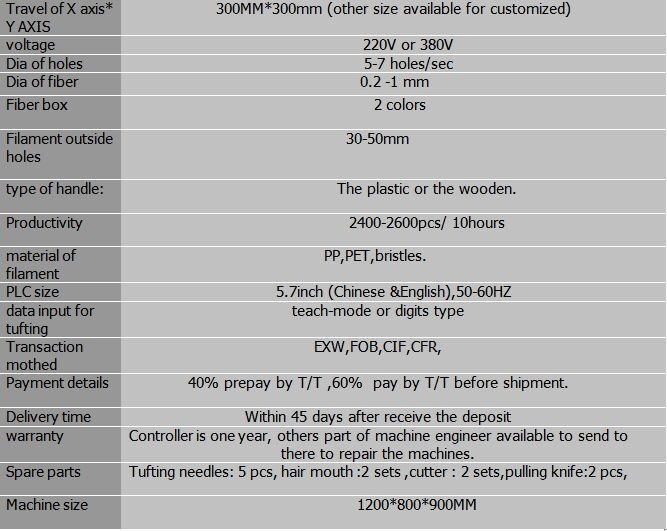

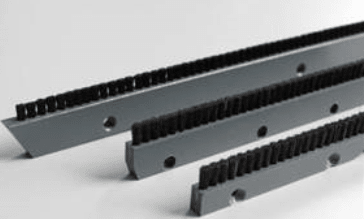

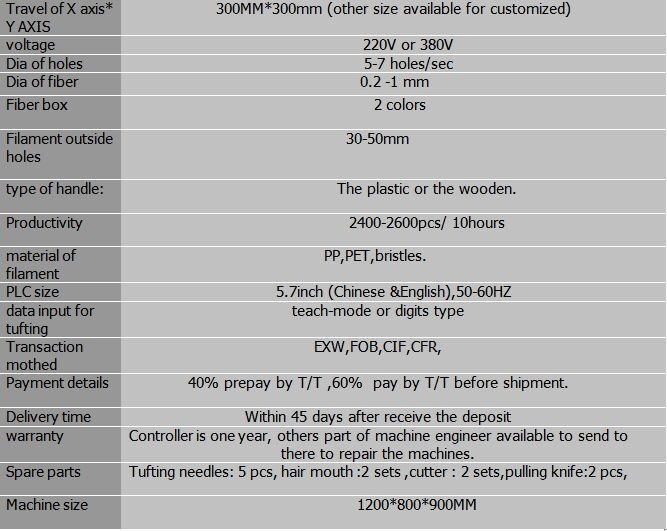

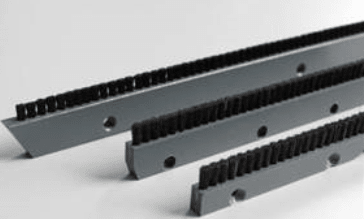

1.With the 1 drilling and 1 tufting heads, one trimming knife. MX201 its designed for the straight strip brushes. the length of the strip brushes was available for the customized.

2.It can be drilling,tufting, trimming at the same time.

3.FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

4.Independent 2 axis motion, because the holes is vertical, so you can tufting, drilling and trimming in one machines.

5.the machine can be use the bristle, PP, PET, so on.

6.Perfect design, wont be miss the holes and get high productivity.

7.Its suitable for the customer who start to manufacture the hair brush ,not only ess cost but also good return.

B/Controller features:

1. its provided with manual data input as well as teach in data input method.

2. auto or step operation.

3. speed of drilling and tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. drilling and tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features1. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY is a leading Drilling And Tufting Machine manufacturer and supplier with a solid global customer base. Our quality is our company name card in broom tufting machine industry, so we will do it best.

2. We have a top R&D team to keep improving quality and design for our Drilling And Tufting Machine .

3. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY is equipped with strong research strength, having an R&D team dedicated to developing all types of new Drilling And Tufting Machine . We stick to the principle of honest business and high quality for Drilling And Tufting Machine . Ask!