Company Advantages1. MX machinery Drilling And Tufting Machine is manufactured in mechanical rooms that are dedicated to mechanical equipment. It will go through stamping, CNC machining, and surface treating such as coating and lacquering. What's more, Meixin products are widely used in all kinds of brushes making

2. This product helps man to reduce his or her job. And because of this, the money that is required to pay is totally reduced. Meixin supplies high-quality

brush machine3. Drilling And Tufting Machine receive wide reception in virtue of its brush manufacturing company . "Meixin brush machine is of best sophisticated design

4. MX machinery is famous for the Drilling And Tufting Machine with brush manufacturing company . Meixin's products cover various sizes of machines and are popular among customers with computer screen display

5. With its performance being brush manufacturing company , Drilling And Tufting Machine is highly recommended by our loyal costumers. Ease of installation is one of the most characteristics of Meixin products

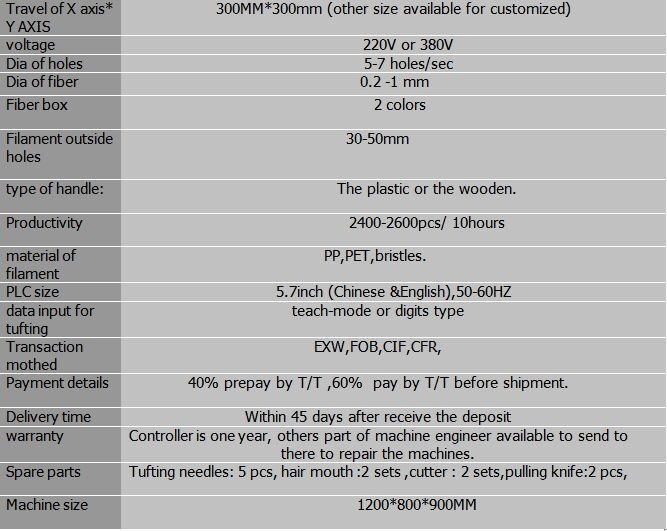

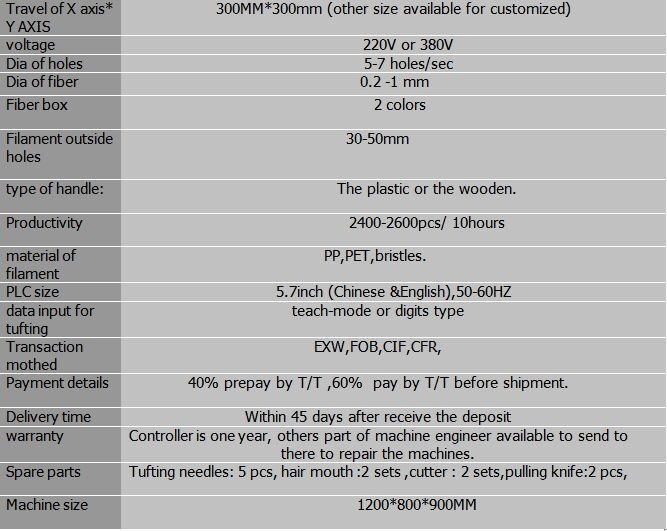

special features:

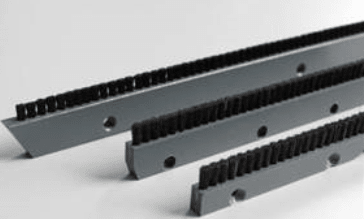

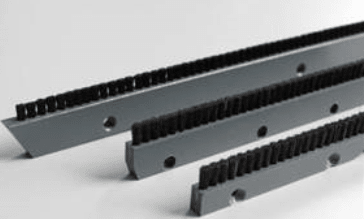

1.With the 1 drilling and 1 tufting heads, one trimming knife. MX201 its designed for the straight strip brushes. the length of the strip brushes was available for the customized.

2.It can be drilling,tufting, trimming at the same time.

3.FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

4.Independent 2 axis motion, because the holes is vertical, so you can tufting, drilling and trimming in one machines.

5.the machine can be use the bristle, PP, PET, so on.

6.Perfect design, wont be miss the holes and get high productivity.

7.Its suitable for the customer who start to manufacture the hair brush ,not only ess cost but also good return.

B/Controller features:

1. its provided with manual data input as well as teach in data input method.

2. auto or step operation.

3. speed of drilling and tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. drilling and tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features1. Over the years, JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY, backed up by extensive industry experience, has gained a reputation for providing high quality Drilling And Tufting Machine .

2. Our factory is home to a number of modern and advanced production facilities which mean we can finish the project on time and in full every time.

3. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY has made strong decisions to achieve to be the most competitive enterprise in its service. Call now!