Company Advantages1. MX machinery brush manufacturers ltd is marticulous manufactured. Cutting-edge technologies such as sensing, computer science, intelligence and programmable logic controller technology are used. Ease of installation is one of the most characteristics of Meixin products

2. Using this product helps reduce workers' workload and cut working time. It has been proved to be more efficient than workers' operations. All our products are made by highly advanced technology

3. The product is stable in performance and excellent in durability. The quality of the products also has been strictly controlled by Meixin

4. The product undergoes rigorous quality checks under the supervision of qualified professionals to ensure quality. Meixin's products cover various sizes of machines and are popular among customers with computer screen display

special features:

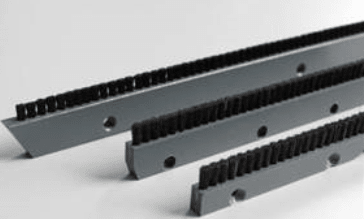

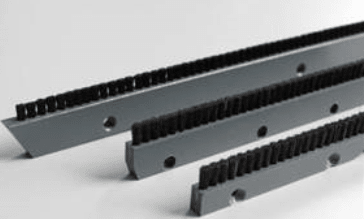

1.With the 1 drilling and 1 tufting heads, one trimming knife. MX201 its designed for the straight strip brushes. the length of the strip brushes was available for the customized.

2.It can be drilling,tufting, trimming at the same time.

3.FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

4.Independent 2 axis motion, because the holes is vertical, so you can tufting, drilling and trimming in one machines.

5.the machine can be use the bristle, PP, PET, so on.

6.Perfect design, wont be miss the holes and get high productivity.

7.Its suitable for the customer who start to manufacture the hair brush ,not only ess cost but also good return.

B/Controller features:

1. its provided with manual data input as well as teach in data input method.

2. auto or step operation.

3. speed of drilling and tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. drilling and tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features1. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY includes a massive factory foundation with a massive manufacturing capacity of producing Drilling And Tufting Machine . JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY has employed the most innovative and expert R&D team.

2. The JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY R&D staff are highly skilled.

3. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY has several senior technicians who is able to provide customer technical assistance for broom tufting machine. At MX machinery, the job is to aid Drilling And Tufting Machine in their pursuit of excellence. Get info!