The Ultimate Guide To Brush Making Machine Prices: Factors To Consider Before Buying

Are you in the market for a brush making machine but overwhelmed by the variety of options and prices available? Look no further! Our comprehensive guide on brush making machine prices will equip you with the knowledge and factors you need to consider before making a purchase. From budget-friendly options to top-of-the-line models, we've got you covered. Dive in and make an informed decision on your next investment in brush making machinery.

- Understanding the different types of brush making machines available

When it comes to purchasing a brush making machine, it is crucial to understand the different types available in the market. This ultimate guide will walk you through the various factors to consider before making a purchase, with a specific focus on brush making machine prices.

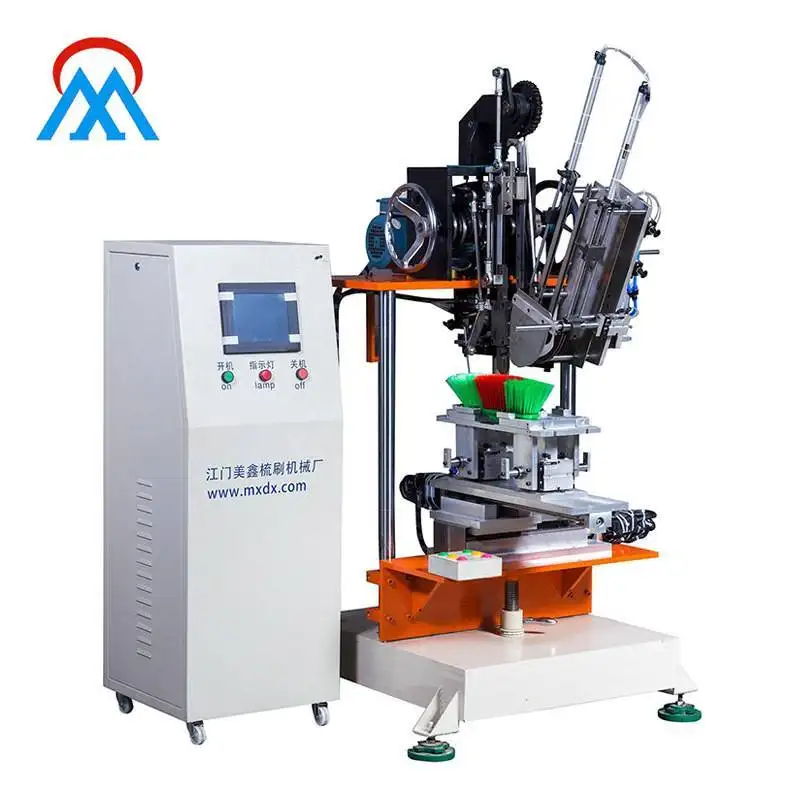

One of the first things to consider when looking at brush making machines is the type of machine you need. There are three main types of brush making machines: tufting machines, twisting machines, and drilling machines. Tufting machines are used for making brushes with bristles that are punched into a backing material, while twisting machines are used for making twisted brush filaments. Drilling machines, on the other hand, are used for making brushes with holes drilled through the backing material for the bristles to be inserted.

Each type of machine has its own set of advantages and disadvantages, so it is important to carefully consider your specific needs before making a decision. Tufting machines are generally the most versatile and can be used for a wide range of brush types, but they can also be the most expensive. Twisting machines are more specialized and are best suited for making brushes with a specific type of filament, while drilling machines are ideal for making brushes with unique designs or patterns.

In addition to the type of machine, another important factor to consider is the price. Brush making machine prices can vary widely depending on the brand, size, and features of the machine. It is important to set a budget and stick to it, but also keep in mind that investing in a higher quality machine may result in more efficient production and higher quality brushes in the long run.

When comparing prices, be sure to consider the overall cost of ownership, including maintenance, repairs, and replacement parts. It is also helpful to research customer reviews and talk to other brush manufacturers to get a sense of the reliability and performance of different machines.

Ultimately, the decision to purchase a brush making machine should not be taken lightly. By understanding the different types of machines available and carefully considering factors such as price, you can make an informed decision that will benefit your business in the long term. Remember to do your research, ask questions, and consider all of your options before making a final decision.

- Evaluating the key factors that influence brush making machine prices

In the world of manufacturing, brush making machines play a crucial role in the production of various types of brushes. Whether it is for cleaning, painting, or cosmetic purposes, these machines are essential for ensuring efficiency and quality in the brush making process. However, when it comes to purchasing a brush making machine, one of the most important considerations is the price.

The cost of a brush making machine can vary significantly depending on a number of factors. In this article, we will delve into the key factors that influence brush making machine prices, helping you make an informed decision before making a purchase.

One of the primary factors that impact the price of a brush making machine is its size and capacity. Larger machines with higher production capacities will typically come with a higher price tag compared to smaller, more compact models. This is because larger machines are able to produce a greater volume of brushes in a shorter amount of time, making them ideal for businesses with high production demands.

Another factor that can influence the price of a brush making machine is the technology and features that it offers. Modern machines equipped with advanced technology such as automated controls, precision cutting mechanisms, and laser-guided systems will generally be more expensive than older, more basic models. These advanced features not only improve the efficiency and accuracy of the brush making process but also contribute to the overall quality of the final product.

Additionally, the type of brushes that a machine is capable of producing can also impact its price. Machines designed for producing specialized brushes, such as those used in the cosmetics industry or for industrial applications, may cost more than machines that are designed for more general-purpose brushes. The complexity of the brush design, the materials used, and the level of customization required can all influence the price of the machine.

Furthermore, the brand and reputation of the manufacturer can also play a role in determining the price of a brush making machine. Well-known and established manufacturers with a reputation for quality and reliability may charge a premium for their machines compared to lesser-known or newer manufacturers. However, investing in a machine from a reputable manufacturer can often provide added peace of mind in terms of performance and durability.

In conclusion, when considering the purchase of a brush making machine, it is important to evaluate the key factors that influence its price. By taking into account factors such as size and capacity, technology and features, types of brushes produced, and the reputation of the manufacturer, you can make an informed decision that meets your specific production needs and budget. Ultimately, the price of a brush making machine should be viewed as an investment in the efficiency and quality of your brush production process.

- Comparing the cost of new versus used brush making machines

When it comes to purchasing a brush making machine, one of the most important factors to consider is the price. In this comprehensive guide, we will delve into the intricacies of brush making machine prices, specifically comparing the cost of new machines versus used machines.

Purchasing a new brush making machine can be a significant investment, with prices varying depending on the brand, size, and capabilities of the machine. New brush making machines are typically more expensive than their used counterparts, but they often come with the latest technology and features that can increase efficiency and productivity. Additionally, new machines often come with warranties and customer support, which can provide peace of mind for buyers.

On the other hand, purchasing a used brush making machine can be a cost-effective option for those on a budget. Used machines are typically sold at a lower price than new machines, making them an attractive option for small businesses or startups looking to save on expenses. However, it's important to thoroughly inspect a used machine before purchasing to ensure that it is in good working condition and will meet your production needs.

When comparing the cost of new versus used brush making machines, there are several factors to consider. These include the age and condition of the machine, the reputation of the manufacturer, the availability of spare parts, and the level of customization and automation. It's important to weigh these factors carefully before making a decision, as choosing the right machine can have a significant impact on your business's bottom line.

In addition to considering the cost of the machine itself, it's also important to factor in additional expenses such as shipping, installation, training, and maintenance. These costs can vary depending on the size and complexity of the machine, so it's important to budget accordingly to avoid any unexpected surprises.

Ultimately, when it comes to purchasing a brush making machine, the decision between buying new or used will depend on your specific needs and budget. By carefully weighing the pros and cons of each option and considering the factors mentioned in this guide, you can make an informed decision that will benefit your business in the long run.

In conclusion, brush making machine prices can vary significantly depending on whether you choose to buy new or used. By carefully considering the factors outlined in this guide, you can make a decision that will benefit your business and help you achieve your production goals.

- Tips for negotiating the best price on a brush making machine

Brush making machines are essential equipment for anyone looking to start or expand a brush making business. However, the cost of these machines can vary greatly depending on various factors. In this ultimate guide, we will discuss the key factors to consider before buying a brush making machine and provide tips on how to negotiate the best price.

One of the main factors that determine the price of a brush making machine is its size and production capacity. Larger machines with higher production capacities tend to be more expensive than smaller ones. Therefore, it is important to consider your production needs and budget before making a decision. If you are just starting out, you may want to opt for a smaller machine to keep costs down. However, if you are looking to scale up your business, investing in a larger machine may be a wise decision in the long run.

Another important factor to consider is the quality of the machine. Higher quality machines are typically more expensive but can provide better performance and durability. It is important to do thorough research on the various brands and models available in the market to ensure you are getting a machine that meets your production needs and quality standards. Additionally, consider the warranty and after-sales support offered by the manufacturer, as this can impact the overall cost of the machine in the long term.

When negotiating the price of a brush making machine, there are several tips that can help you get the best deal. Firstly, do your homework and compare prices from different suppliers to get an idea of the average market price. This will give you some leverage when negotiating with potential sellers. Additionally, be prepared to walk away if the price is too high, as this can demonstrate to the seller that you are serious about getting a good deal.

It is also important to negotiate other terms besides just the price, such as payment terms, delivery schedule, and training and installation services. Some suppliers may be willing to offer discounts or additional services to sweeten the deal. By negotiating these terms, you can potentially save money and ensure a smooth and hassle-free purchase process.

In conclusion, the price of a brush making machine is influenced by various factors such as size, production capacity, quality, and brand. Before making a purchase, it is important to consider these factors carefully and do thorough research to ensure you are getting the best value for your money. By following the tips outlined in this guide, you can negotiate the best price on a brush making machine and set yourself up for success in the brush making industry. Remember, a well-informed buyer is more likely to get a good deal.

- Important considerations to keep in mind before making a purchase

When it comes to purchasing a brush making machine, there are various factors to consider before making a final decision. The price of the machine is one of the most important considerations to keep in mind. In this ultimate guide, we will delve into the various factors that can impact brush making machine prices to help you make an informed decision.

One of the key factors that can influence the price of a brush making machine is the type of machine you are looking to purchase. There are different types of brush making machines available on the market, ranging from manual machines to fully automated ones. The complexity and capabilities of the machine will play a significant role in determining its price. Manual machines are typically more affordable, while fully automated machines come with a heftier price tag.

Another important factor to consider is the size and capacity of the machine. Larger machines that can produce a higher volume of brushes at a faster rate tend to be more expensive. If you have a high production demand, investing in a larger machine may be worth the higher price. However, if you are only looking to produce a small number of brushes, a smaller machine may be a more cost-effective option.

The quality of the materials used in the construction of the machine can also impact its price. Machines made with high-quality materials and precision engineering are likely to cost more upfront but can offer better performance and longevity in the long run. Cheaper machines may be more budget-friendly initially, but could end up costing more in repairs and replacements.

Additionally, the brand and reputation of the manufacturer can affect the price of the machine. Well-established brands with a proven track record of producing high-quality machines may command a higher price than lesser-known brands. It is important to do your research and choose a reputable manufacturer that offers reliable products and good customer support.

Other factors that can impact brush making machine prices include additional features and customization options. Machines with advanced features such as programmable settings, digital controls, and automatic material feeders may cost more than basic models. Customization options such as different brush sizes, shapes, and bristle types can also add to the overall cost of the machine.

In conclusion, when considering the price of a brush making machine, it is important to weigh all these factors carefully to make an informed decision. By understanding the various considerations that can impact machine prices, you can choose a machine that meets your production needs and budget requirements. Remember to prioritize quality and reliability over price alone to ensure that your investment pays off in the long run.

Conclusion

In conclusion, purchasing a brush making machine is a significant investment for any business in the industry. By considering factors such as machine type, production capacity, quality of materials, and additional features, buyers can make a well-informed decision that best suits their needs. While price is an important factor to consider, it should not be the sole determinant in making a purchase. By doing thorough research and weighing all options, buyers can ensure they are investing in a machine that will help them produce high-quality brushes efficiently and effectively. With the ultimate guide to brush making machine prices in mind, buyers can make a confident choice that will benefit their business for years to come.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019