The Guide To Brush Making Machine Prices: What You Need To Know

Are you thinking about investing in a brush making machine but unsure about the prices? Look no further! In this comprehensive guide, we break down everything you need to know about brush making machine prices. From factors that influence the cost to top brands to consider, this article will help you make an informed decision. Keep reading to learn more!

Factors affecting brush making machine prices

In the world of manufacturing, brush making machines are essential tools for producing a wide range of brushes, from household cleaning brushes to industrial scrubbers. As with any machinery, the price of brush making machines can vary significantly depending on various factors. In this guide, we will explore the key factors that affect brush making machine prices, helping you understand what goes into the cost of these essential machines.

One of the most significant factors that influence the price of a brush making machine is its size and capacity. Larger machines that are capable of producing a higher volume of brushes in a shorter amount of time typically come with a higher price tag. These machines are often more complex and require more materials to manufacture, leading to a higher overall cost. On the other hand, smaller machines designed for lower production volumes are generally more affordable but may not be suitable for larger scale operations.

Another crucial factor that affects the price of a brush making machine is the level of automation it offers. Fully automated machines that require minimal human intervention tend to be more expensive than semi-automated or manual machines. While automation can significantly increase production efficiency and reduce labor costs in the long run, it also comes with a higher upfront investment. Manufacturers must weigh the benefits of automation against the cost when deciding which type of machine to purchase.

The quality and durability of the materials used in the construction of a brush making machine also play a significant role in determining its price. Machines made from high-quality materials such as stainless steel or aluminum are likely to last longer and require less maintenance, but they also come with a higher price tag. Cheaper machines made from lower-quality materials may be more affordable upfront, but they are more prone to breakage and may end up costing more in the long run through repairs and replacements.

Furthermore, the brand and reputation of the manufacturer can also impact the price of a brush making machine. Well-known and established brands that have a reputation for producing high-quality machines may charge a premium for their products. However, this higher price may be justified by the reliability and performance of the machine. On the other hand, lesser-known or generic brands may offer more affordable options, but there is often a trade-off in terms of quality and support.

In conclusion, the price of a brush making machine is influenced by a variety of factors, including its size and capacity, level of automation, materials used, and the reputation of the manufacturer. It is essential for manufacturers to carefully consider these factors when purchasing a brush making machine to ensure that they are getting the best value for their investment. By understanding the key factors that affect brush making machine prices, businesses can make informed decisions and select a machine that meets their production needs and budget.

Types of brush making machines available

Brush making machines are essential tools for creating various types of brushes, from household cleaning brushes to industrial brushes used in manufacturing. The cost of these machines can vary greatly depending on the type of brush being produced, the complexity of the design, and the features of the machine itself. In this guide, we will explore the different types of brush making machines available and the factors that influence their prices.

1. CNC Brush Making Machine:

One of the most advanced types of brush making machines is the CNC (Computer Numerical Control) brush making machine. These machines are equipped with computerized controls that allow for precise and intricate brush designs to be created with ease. The cost of CNC brush making machines can be quite high, as they offer advanced features and capabilities that are not found in other types of machines. However, the ability to produce high-quality brushes quickly and efficiently may justify the higher price tag for many brush manufacturers.

2. Manual Brush Making Machine:

On the other end of the spectrum are manual brush making machines, which require more labor and skill to operate but are generally more affordable. These machines are often used for smaller-scale brush production and may be a good option for individuals or small businesses looking to start a brush making operation on a budget. While manual machines may not have the same level of automation as CNC machines, they can still produce quality brushes with the right expertise and attention to detail.

3. Semi-Automatic Brush Making Machine:

Semi-automatic brush making machines offer a middle ground between manual and CNC machines. These machines have some automated features, such as brush trimming and knotting, that can help increase production efficiency and reduce labor costs. The price of semi-automatic machines will vary depending on the level of automation and the specific features included. While they may not offer the same level of precision as CNC machines, semi-automatic machines can still produce high-quality brushes at a more affordable price point.

4. Multi-Function Brush Making Machine:

Multi-function brush making machines are designed to produce a variety of brush types, sizes, and shapes. These machines often come equipped with interchangeable tooling and attachments that allow for versatility in brush production. While multi-function machines may have a higher initial cost, they can be a cost-effective option for manufacturers looking to produce a wide range of brushes without investing in multiple machines. The ability to switch between different brush styles quickly and easily can help improve production efficiency and reduce downtime.

In conclusion, the price of a brush making machine will depend on the type of machine, its features, and the level of automation it offers. While CNC machines may offer the most advanced capabilities, manual, semi-automatic, and multi-function machines can also be viable options for brush manufacturers at different price points. Consider your production needs, budget, and long-term goals when choosing a brush making machine to ensure you get the best value for your investment.

Comparing different brands and models

Brush making machines are an essential piece of equipment in the manufacturing process of various types of brushes, including toothbrushes, cleaning brushes, and paintbrushes. These machines are designed to automate the process of creating the bristle patterns and attaching them to the brush base, making the production process more efficient and cost-effective. However, when it comes to investing in a brush making machine, the price can vary significantly depending on the brand and model.

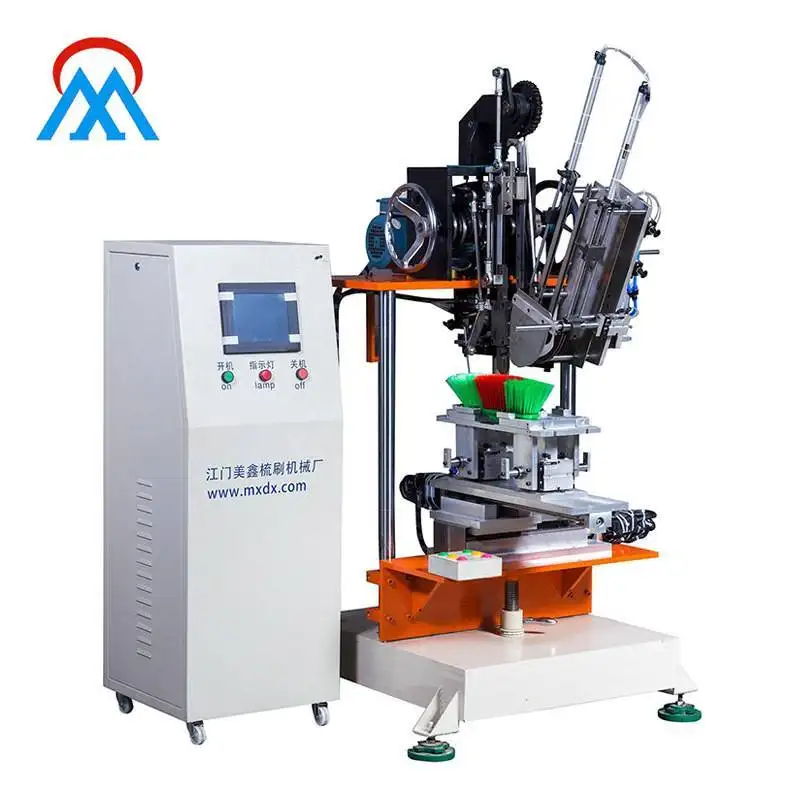

When comparing different brands and models of brush making machines, there are several factors to consider that can impact the price. One of the biggest factors is the brand reputation and quality of the machine. Some well-known brands in the industry, such as Borghi, Zahoransky, and Meixin, are known for their high-quality machines that are durable and reliable. These machines may come with a higher price tag, but they are often worth the investment for their long-term performance and efficiency.

Another factor that can influence the price of a brush making machine is the specific features and capabilities it offers. Some machines may come with advanced technology and automation features that can help improve production efficiency and quality. These features, such as automatic bristle cutters, programmable settings, and touchscreen interfaces, can add to the overall cost of the machine but can also provide significant benefits in terms of productivity and quality.

In addition to brand reputation and features, the size and capacity of the machine can also impact the price. Larger machines that are capable of producing a higher volume of brushes at once will generally be more expensive than smaller machines. Similarly, machines that are designed for specialized brush types, such as toothbrushes or paintbrushes, may also come with a higher price tag due to their specific capabilities and requirements.

When comparing different brands and models of brush making machines, it is important to consider not just the upfront cost, but also the overall value and return on investment. A cheaper machine may seem like a cost-effective option initially, but if it lacks the features and quality needed for efficient production, it may end up costing more in the long run in terms of maintenance and downtime.

In conclusion, when researching brush making machine prices, it is important to consider the brand reputation, features, size, and capacity of the machine to determine the best value for your specific needs. By comparing different brands and models, you can make an informed decision that will benefit your manufacturing process in the long term.

Understanding the cost-benefit analysis

Brush making machines are essential pieces of equipment for any business in the brush manufacturing industry. Whether you are a small startup or a well-established company, understanding the cost-benefit analysis of investing in a brush making machine is crucial for making informed decisions. In this comprehensive guide, we will delve into the various factors that influence brush making machine prices and help you navigate through the complexities of purchasing this equipment.

When it comes to brush making machine prices, there are several key factors to consider. The first and most obvious factor is the type of machine you are looking to purchase. Brush making machines come in a variety of models, each with its own set of features and capabilities. From simple manual machines to fully automated systems, the price can vary greatly depending on the level of sophistication and technology involved. It is important to assess your specific needs and budget constraints to determine the most suitable machine for your business.

In addition to the type of machine, the brand and reputation of the manufacturer also play a significant role in determining the price. Established brands with a solid track record of reliability and customer satisfaction may command higher prices compared to lesser-known brands. However, investing in a reputable brand can offer peace of mind in terms of quality and after-sales support, ultimately leading to long-term cost savings.

Another important factor to consider when evaluating brush making machine prices is the overall cost of ownership. This includes not just the initial purchase price, but also ongoing maintenance, repair, and operational costs. It is essential to factor in these additional expenses to make an accurate cost-benefit analysis and determine the true value of the investment.

Furthermore, the level of customization and flexibility of the machine can also impact its price. Machines that offer a wide range of customization options and can accommodate various brush sizes and materials may come at a higher cost but can provide greater versatility and efficiency in production. On the other hand, simpler machines with limited capabilities may be more budget-friendly but may not be suitable for all types of brush manufacturing needs.

Ultimately, the decision to invest in a brush making machine should be based on a thorough understanding of the cost-benefit analysis. By considering factors such as machine type, brand reputation, total cost of ownership, and customization options, you can make an informed decision that aligns with your business goals and budget constraints. With the right machine in place, you can streamline your production processes, improve efficiency, and ultimately increase profitability in the long run.

Tips for negotiating the best price

Brush making machine price is a crucial factor to consider when looking to invest in this type of machinery. Whether you are a small business owner looking to expand your brush production capabilities or a large industrial manufacturer in need of high-volume production, negotiating the best price for a brush making machine is key to maximizing your return on investment.

When it comes to negotiating the best price for a brush making machine, there are several tips that can help you navigate the process and secure the most favorable terms. Here are some important factors to keep in mind:

1. Research and Compare Prices: Before entering into negotiations with a supplier, it is important to research and compare prices from multiple vendors. This will give you a better understanding of the market rate for brush making machines and help you identify any outliers or overly inflated prices.

2. Understand the Features and Specifications: Brush making machines come in a variety of models with different features and specifications. It is important to understand your specific production needs and requirements in order to determine which machine is the best fit for your business. By having a clear understanding of the features and specifications you need, you can negotiate a more accurate price based on your specific requirements.

3. Consider the Total Cost of Ownership: When negotiating the price of a brush making machine, it is important to consider the total cost of ownership. This includes not only the initial purchase price but also ongoing maintenance, repair, and operational costs. By factoring in the total cost of ownership, you can negotiate a more comprehensive price that takes into account all associated expenses.

4. Build a Relationship with the Supplier: Building a strong relationship with the supplier can also help in negotiating the best price for a brush making machine. By establishing trust and open communication with the supplier, you may be able to secure a more competitive price or negotiate additional perks such as extended warranties or discounts on future purchases.

5. Be Willing to Walk Away: While it is important to negotiate the best price for a brush making machine, it is also crucial to be willing to walk away if the terms are not favorable. By being prepared to walk away from a deal that does not meet your price or quality requirements, you can maintain control of the negotiation process and potentially find a better offer elsewhere.

In conclusion, negotiating the best price for a brush making machine requires careful research, understanding of your needs, and effective communication with the supplier. By following these tips and considering the total cost of ownership, you can secure a competitive price for a brush making machine that meets your production needs and budget constraints.

Conclusion

In conclusion, understanding the factors that impact brush making machine prices is crucial for making informed purchasing decisions. By considering the machine's specifications, brand reputation, and additional features, buyers can ensure they are getting the best value for their investment. Remember to also factor in maintenance and operating costs to fully assess the overall affordability of a brush making machine. With this guide in mind, businesses can confidently navigate the market and find the perfect machine to meet their production needs. So, whether you are a small start-up or a large corporation, taking the time to research and compare prices will ultimately result in a successful brush making operation.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019