The Cost Of Efficiency: Exploring Brush Making Machine Prices

Are you wondering about the price of brush making machines and how it may impact your business? Look no further as we delve into the cost of efficiency in our latest article, "The Cost of Efficiency: Exploring Brush Making Machine Prices." Whether you're a seasoned professional or a newcomer to the industry, this article will provide valuable insights into the world of brush making machines and how their prices can affect your bottom line. Join us as we uncover the factors that influence pricing and help you make informed decisions for your business.

- Factors influencing brush making machine prices

When it comes to purchasing a brush making machine, there are a variety of factors that can influence the overall price. These factors can range from the machine's size and capacity to its level of automation and technology. Understanding the key influencers behind brush making machine prices can help businesses make informed decisions and find the right balance between cost and efficiency.

One of the primary factors that can impact brush making machine prices is the machine's size and capacity. Larger machines with higher production capacities will typically come with a higher price tag. These machines are able to produce a larger volume of brushes in a shorter amount of time, making them ideal for companies with high production demands. However, smaller machines with lower capacities can also be a cost-effective option for businesses with lower production needs.

Another key factor that can affect brush making machine prices is the level of automation. Machines that are fully automated and require minimal human intervention tend to be more expensive than semi-automated or manual machines. While automated machines can increase efficiency and accuracy, they require a larger upfront investment. Businesses should weigh the benefits of automation against the cost implications to determine the best option for their production needs.

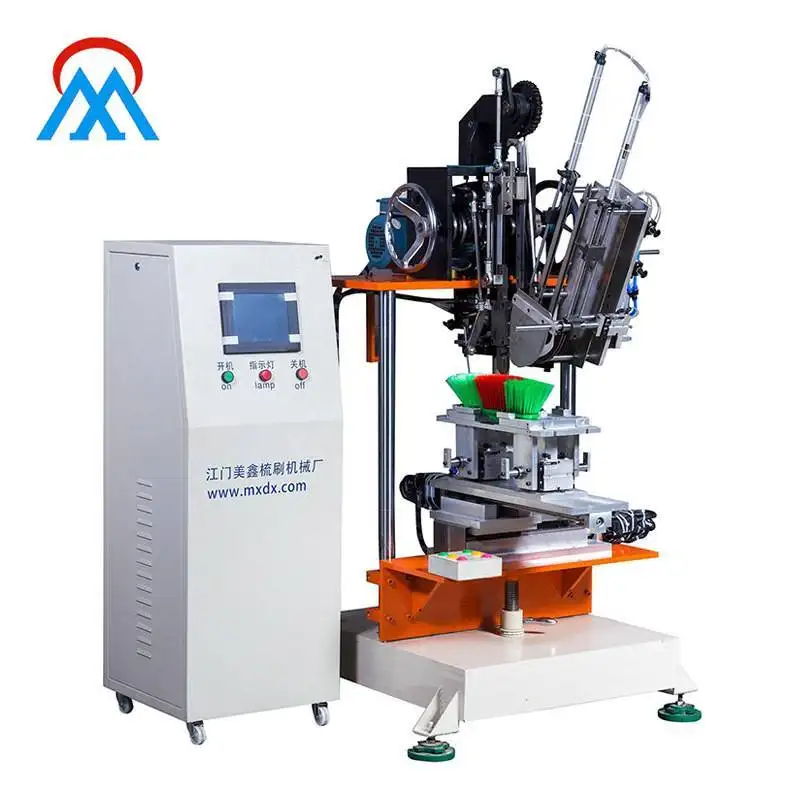

The technology used in brush making machines can also play a significant role in determining the overall price. Machines equipped with advanced technologies such as computerized controls, precision sensors, and programmable settings will typically cost more than machines with basic functionalities. These advanced technologies can enhance the quality and consistency of the brushes produced, but they may not be necessary for every business.

Additionally, the brand and reputation of the manufacturer can impact brush making machine prices. Well-known manufacturers with a long history of producing high-quality machines may demand a higher price for their products. While these machines may come with a higher price tag, they often come with a warranty and after-sales support that can provide peace of mind to buyers.

In conclusion, brush making machine prices are influenced by a variety of factors, including size, capacity, automation level, technology, and manufacturer. Businesses should carefully consider these factors to find a machine that meets their production needs while staying within budget. By understanding the key influencers behind brush making machine prices, businesses can make informed decisions and invest in a machine that will improve efficiency and productivity in the long run.

- Popular types and their respective price ranges

Brush making machines are essential tools for manufacturers in the brush industry, helping to streamline the production process and increase efficiency. In this article, we will explore the popular types of brush making machines and their respective price ranges, shedding light on the cost of efficiency in this sector.

The price of a brush making machine can vary significantly depending on the type and features it offers. One of the most popular types of brush making machines is the CNC brush making machine, which is highly automated and can produce a wide range of brush designs with precision and consistency. These machines typically come with a higher price tag, ranging from $10,000 to $50,000 or more, depending on the brand and specifications.

Another popular type of brush making machine is the semi-automatic brush making machine, which offers a balance between automation and manual operation. These machines are more affordable than CNC machines, with prices ranging from $5,000 to $20,000. They are suitable for small to medium-sized brush manufacturers who require flexibility in their production process.

For those with a limited budget, manual brush making machines are a cost-effective option. These machines require more manual labor and are less efficient compared to automated machines, but they are suitable for small-scale production or as a starter machine for new businesses. Prices for manual brush making machines range from $1,000 to $5,000, making them a budget-friendly choice for entrepreneurs.

When considering the price of a brush making machine, it is essential to factor in additional costs such as maintenance, training, and spare parts. Regular maintenance is crucial to ensure the longevity and performance of the machine, and training for operators is essential to maximize productivity and efficiency. Spare parts should also be readily available to minimize downtime in case of breakdowns.

In conclusion, the cost of efficiency in brush making machines varies depending on the type and features of the machine. While CNC machines offer the highest level of automation and precision, they come with a higher price tag. Semi-automatic machines provide a balance between automation and manual operation at a more affordable price point, while manual machines are a budget-friendly option for small-scale production. By considering the price range and features of different types of brush making machines, manufacturers can make an informed decision on the best machine for their production needs.

- Comparing manual vs automated brush making machines

Brush making machines have revolutionized the manufacturing process for companies in the brush industry, offering the ability to produce brushes on a larger scale with increased efficiency. One key decision that companies must make when investing in a brush making machine is whether to opt for a manual or automated machine. In this article, we will explore the cost implications of choosing between manual and automated brush making machines.

Manual brush making machines are typically less expensive than their automated counterparts, with prices ranging from a few hundred to a few thousand dollars. These machines require manual operation, with workers feeding the materials into the machine and monitoring the production process. While manual machines may be more affordable upfront, they often require more labor and can result in lower production output compared to automated machines.

On the other hand, automated brush making machines are pricier, with costs ranging from tens of thousands to hundreds of thousands of dollars. However, these machines offer increased efficiency and productivity, as they can produce a larger number of brushes in a shorter amount of time with minimal human intervention. In the long run, the higher upfront cost of automated machines may be offset by the savings in labor costs and increased production capacity.

When comparing manual and automated brush making machines, it is important to consider not only the initial investment cost but also the overall cost of ownership. Manual machines may be cheaper upfront, but they may require more maintenance and repairs over time, leading to higher long-term costs. Automated machines, on the other hand, are often more durable and require less maintenance, resulting in lower overall costs in the long run.

Additionally, the cost of efficiency should also be taken into account when choosing between manual and automated brush making machines. While manual machines may be more affordable, they may result in slower production times and lower quality control compared to automated machines. Automated machines, with their precision and consistency, can help companies meet production deadlines and maintain consistent quality standards, ultimately leading to higher customer satisfaction and sales.

In conclusion, the cost of efficiency is a crucial factor to consider when evaluating brush making machine prices. While manual machines may be a more cost-effective option upfront, automated machines offer increased efficiency, productivity, and quality control, which can ultimately lead to higher profits and a competitive edge in the market. By weighing the upfront costs against long-term benefits, companies can make an informed decision on whether to invest in a manual or automated brush making machine.

- Understanding the long-term cost benefits of efficient machines

Brush making machines are an essential piece of equipment for businesses in the manufacturing industry. These machines are used to efficiently produce various types of brushes, from household cleaning brushes to industrial machinery brushes. However, the cost of purchasing and operating these machines is a significant consideration for business owners.

When exploring brush making machine prices, it is essential to consider not only the upfront cost but also the long-term cost benefits of investing in efficient machines. While efficient machines may have a higher initial price tag, they can ultimately save businesses money in the long run through increased productivity, lower maintenance costs, and reduced energy consumption.

One of the key benefits of investing in efficient brush making machines is increased productivity. These machines are designed to produce a high volume of brushes quickly and consistently, which can help businesses meet customer demands and increase their profits. Additionally, efficient machines typically have lower downtime rates, meaning less time is spent on maintenance and repairs, allowing for continuous production.

Another cost-saving benefit of efficient machines is lower maintenance costs. These machines are designed to be more durable and reliable, reducing the need for frequent repairs and replacements. By investing in a high-quality machine upfront, businesses can avoid the costs associated with regular maintenance and unexpected breakdowns.

Additionally, efficient brush making machines are designed to be energy-efficient, helping businesses reduce their overall energy consumption and lower their utility bills. These machines are equipped with advanced technology and features that optimize energy usage while maintaining high production standards. By investing in an energy-efficient machine, businesses can save money on their operating costs in the long term.

Overall, while the initial cost of purchasing an efficient brush making machine may be higher, the long-term cost benefits far outweigh the upfront investment. By considering the productivity gains, lower maintenance costs, and reduced energy consumption of efficient machines, businesses can make a wise investment that will pay off in the long run. When exploring brush making machine prices, it is crucial for businesses to prioritize efficiency and consider the long-term cost benefits of investing in high-quality machines.

- Exploring budget-friendly options for small businesses

In today's competitive business landscape, small businesses are constantly on the lookout for cost-effective solutions to increase efficiency and productivity. One of the key investments for businesses in the manufacturing industry is a brush making machine, which can significantly streamline the production process and help businesses meet the growing demands of their customers. However, with the myriad of options available in the market, finding a budget-friendly brush making machine can be a daunting task.

When it comes to purchasing a brush making machine, the price is often a major consideration for small businesses. The cost of a brush making machine can vary significantly depending on factors such as the brand, model, size, and features. Small businesses looking to invest in a brush making machine must carefully weigh the price against their budget and the potential return on investment.

One of the key factors that can impact the price of a brush making machine is the brand. Established brands with a reputation for high-quality products may come with a higher price tag, but they often offer superior performance and durability. On the other hand, lesser-known brands may offer more affordable options, but businesses must carefully evaluate the quality and reliability of these machines before making a purchase.

Another aspect to consider when exploring brush making machine prices is the model and size of the machine. Larger machines with more advanced features may come with a higher price, but they can also significantly increase production efficiency and output. Small businesses with limited space and production needs may opt for a smaller, more basic model to meet their requirements while staying within budget.

In addition to the initial cost of the machine, businesses must also consider the long-term costs associated with maintenance, repairs, and upgrades. Investing in a high-quality brush making machine that is built to last can help businesses save money in the long run by reducing the need for frequent repairs and replacements. Businesses should also factor in the cost of training employees to operate the machine efficiently and effectively.

When it comes to exploring budget-friendly options for small businesses, there are a few strategies that businesses can consider to save on brush making machine prices. One option is to look for discounts or promotions offered by manufacturers or suppliers. Another option is to consider purchasing a used or refurbished machine, which can often be a more affordable alternative to buying a brand new machine.

In conclusion, the cost of efficiency when it comes to brush making machine prices is a crucial consideration for small businesses looking to streamline their production processes. By carefully evaluating the price, brand, model, and long-term costs of a brush making machine, businesses can make an informed decision that aligns with their budget and production needs. Investing in a high-quality brush making machine can ultimately help businesses increase productivity, meet customer demands, and achieve long-term success in the competitive manufacturing industry.

Conclusion

In conclusion, after exploring the prices of brush making machines, it is clear that efficiency comes at a cost. While investing in a high-quality machine may have a higher upfront price, the long-term benefits in terms of productivity, quality of output, and overall performance make it a worthwhile investment. By understanding your needs and budget constraints, you can make an informed decision on the best brush making machine for your business. Remember, efficiency is key in any manufacturing operation, and the right machine can help you achieve your production goals effectively. So, carefully weigh your options and choose a machine that will help you streamline your production process and ultimately drive success for your business.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019