Revolutionizing Production: Introducing The Pneumatic Filament Cutting Machine

Welcome to the future of production technology! In this article, we will delve into the groundbreaking innovation of the Pneumatic Filament Cutting Machine and how it is revolutionizing the way products are manufactured. Stay tuned to discover how this cutting-edge technology is transforming the production process and providing unprecedented efficiency and precision.

- The Evolution of Traditional Filament Cutting Methods

In the world of production and manufacturing, advancements in technology continue to revolutionize traditional methods, leading to increased efficiency and precision. One such innovation is the Pneumatic Filament Cutting Machine, which has transformed the way filament cutting is done in various industries.

The evolution of traditional filament cutting methods has been a gradual process, with manual cutting tools being the standard for many years. However, as technology has advanced, the need for faster and more accurate cutting methods has become increasingly apparent. The introduction of the Pneumatic Filament Cutting Machine has addressed these issues, offering a solution that is both efficient and precise.

One of the key advantages of the Pneumatic Filament Cutting Machine is its pneumatic cutting mechanism. By using compressed air to power the cutting blade, the machine is able to make clean and precise cuts with minimal effort. This not only improves the accuracy of the cutting process but also increases the speed at which filaments can be cut, ultimately leading to higher production rates.

Furthermore, the Pneumatic Filament Cutting Machine is highly versatile, capable of cutting a wide range of materials with varying thicknesses. This flexibility makes it an ideal tool for manufacturers who work with different types of filaments, allowing them to streamline their production processes and improve overall efficiency.

In addition to its cutting capabilities, the Pneumatic Filament Cutting Machine also offers enhanced safety features. The pneumatic power source eliminates the need for electrical cords, reducing the risk of accidents and ensuring a safer working environment for operators. This not only protects workers from potential hazards but also reduces the likelihood of machine malfunctions, resulting in less downtime and increased productivity.

Overall, the introduction of the Pneumatic Filament Cutting Machine has significantly improved the way filament cutting is done in various industries. Its advanced technology, precision cutting capabilities, versatility, and safety features make it a valuable asset for manufacturers looking to enhance their production processes and stay ahead of the competition. As technology continues to evolve, innovations like the Pneumatic Filament Cutting Machine will continue to shape the future of production, leading to more efficient and cost-effective manufacturing processes.

- Introducing Pneumatic Technology: How It Works

Pneumatic technology has been revolutionizing the way industries operate, and now, it is making waves in the production of filament cutting machines. The introduction of the Pneumatic Filament Cutting Machine has sparked interest and excitement in the manufacturing sector, as it promises to streamline production processes and improve efficiency.

At the heart of this innovation lies pneumatic technology, which utilizes compressed air to power machines and equipment. This technology is known for its reliability, efficiency, and precision, making it an ideal choice for industries that require high-performance machinery. The Pneumatic Filament Cutting Machine harnesses the power of pneumatic technology to offer a cutting-edge solution for filament production.

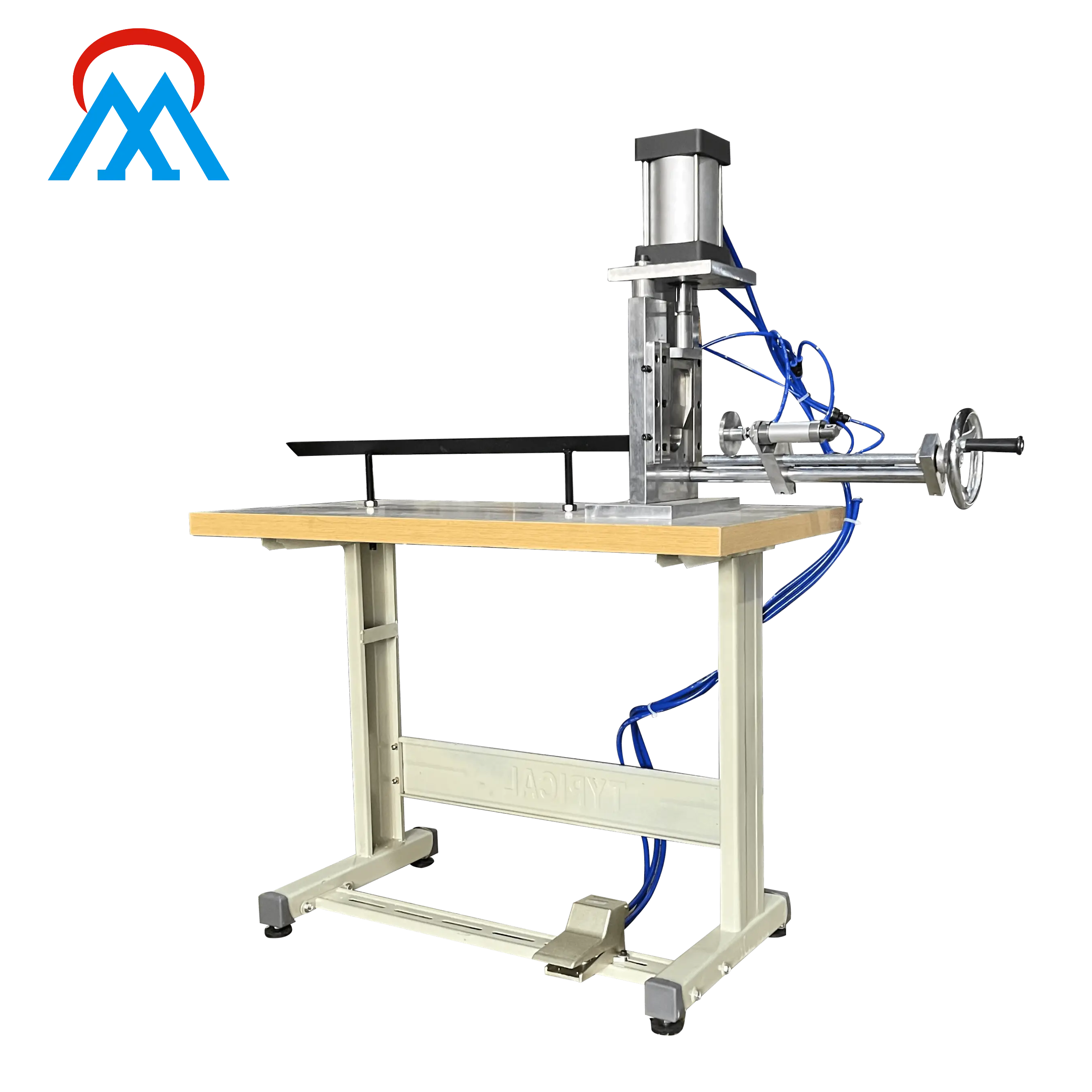

So, how does the Pneumatic Filament Cutting Machine work? This cutting-edge machine features a pneumatic system that controls the cutting process with precision and accuracy. The machine is equipped with a cutting blade that is powered by compressed air, allowing for fast and precise cuts to be made on filaments of various materials. The pneumatic system ensures that the cutting blade operates smoothly and consistently, resulting in clean and uniform cuts every time.

One of the key advantages of the Pneumatic Filament Cutting Machine is its speed and efficiency. With its pneumatic technology, this machine is able to cut filaments at a rapid pace, increasing production output and reducing processing time. This not only results in higher productivity but also helps companies meet tight production deadlines and customer demands.

In addition to speed and efficiency, the Pneumatic Filament Cutting Machine also offers superior precision and accuracy. The pneumatic system allows for fine-tuning of the cutting process, ensuring that each filament is cut to the exact specifications required. This level of precision is crucial in industries where quality control is paramount, such as in the production of medical devices or electronic components.

Furthermore, the Pneumatic Filament Cutting Machine is designed to be user-friendly and easy to operate. The pneumatic system is automated, meaning that the machine can be controlled with minimal manual intervention. This not only reduces the risk of human error but also makes it easier for operators to handle the machine, even without extensive training or experience.

Overall, the introduction of the Pneumatic Filament Cutting Machine represents a significant milestone in the world of production. By incorporating pneumatic technology into the cutting process, this machine offers a high-performance solution that delivers speed, efficiency, precision, and ease of use. As industries continue to evolve and demand for advanced production equipment grows, the Pneumatic Filament Cutting Machine stands out as a game-changer that is set to revolutionize the way filaments are produced.

- Advantages of Pneumatic Filament Cutting Machines

Revolutionizing Production: Introducing the Pneumatic Filament Cutting Machine - Advantages of Pneumatic Filament Cutting Machines

In recent years, advanced technology has paved the way for significant advancements in various industries. One such innovation that has been revolutionizing the production process is the pneumatic filament cutting machine. These cutting-edge machines have quickly become popular among manufacturers due to their numerous advantages and capabilities.

Pneumatic filament cutting machines are designed to cut filaments with precision and efficiency. The pneumatic system utilizes compressed air to power the cutting mechanism, allowing for quick and accurate cuts to be made. This method of cutting is highly effective, resulting in clean and uniform cuts every time.

One of the main advantages of pneumatic filament cutting machines is their speed and consistency. These machines are capable of cutting filaments at a rapid pace, significantly increasing production efficiency. Unlike manual cutting methods, which can be time-consuming and inconsistent, pneumatic machines are able to repeatedly cut filaments with exact precision, ensuring uniformity in each cut.

Furthermore, pneumatic filament cutting machines are incredibly versatile and can be used with a variety of materials. Whether cutting plastic, rubber, or other materials, these machines are able to handle different types of filaments with ease. This versatility makes them suitable for a wide range of industries, including textile manufacturing, automotive, and electronics.

Another key advantage of pneumatic filament cutting machines is their durability and reliability. These machines are built to withstand high-volume production environments and are designed to operate continuously with minimal maintenance. This durability ensures that manufacturers can rely on these machines for consistent and long-lasting performance.

Additionally, pneumatic filament cutting machines offer enhanced safety features compared to traditional cutting methods. With automated cutting processes and safety guards in place, the risk of accidents or injuries is significantly reduced. This not only protects workers but also ensures a safer working environment overall.

In conclusion, the introduction of pneumatic filament cutting machines has revolutionized the production process in various industries. These machines offer numerous advantages, including speed, precision, versatility, durability, and safety. As technology continues to advance, pneumatic filament cutting machines will undoubtedly play a crucial role in improving efficiency and productivity for manufacturers worldwide.

Overall, the adoption of pneumatic filament cutting machines represents a significant step forward in the evolution of production processes. Manufacturers looking to enhance their operations and stay ahead of the competition would be wise to consider integrating these cutting-edge machines into their production line.

- Applications in Various Industries

Revolutionizing Production: Introducing the Pneumatic Filament Cutting Machine - Applications in Various Industries

In the ever-evolving landscape of manufacturing and production, the introduction of cutting-edge technologies has become essential to staying competitive in the market. One such innovation that has been making waves in various industries is the Pneumatic Filament Cutting Machine. This state-of-the-art machine has revolutionized the way filaments are cut, providing unparalleled precision, efficiency, and reliability.

The Pneumatic Filament Cutting Machine operates on the principle of using air pressure to precisely cut filaments with a high level of accuracy. This cutting-edge technology has been widely adopted in industries such as textiles, plastics, automotive, and aerospace, among others, due to its ability to enhance productivity and streamline production processes.

One of the key advantages of the Pneumatic Filament Cutting Machine is its ability to cut a wide range of materials with varying degrees of thickness and density. Whether it is cutting fibrous materials like yarns and fabrics in the textile industry or slicing through tough plastics in the automotive sector, this machine delivers consistent and clean cuts every time.

Furthermore, the Pneumatic Filament Cutting Machine offers unmatched speed and efficiency, allowing manufacturers to increase their output and meet tight production deadlines. With its automated cutting process, this machine eliminates the need for manual labor, reducing the risk of human error and ensuring a higher level of precision in the cutting process.

In the aerospace industry, where precision and quality are paramount, the Pneumatic Filament Cutting Machine has become an indispensable tool for cutting composite materials used in the production of aircraft components. Its ability to cut through tough and durable materials with ease makes it a valuable asset for manufacturers looking to meet the stringent requirements of the aerospace industry.

Moreover, the Pneumatic Filament Cutting Machine is also being used in the medical field for cutting surgical sutures and other delicate medical devices with precision and accuracy. Its sterile cutting environment ensures that medical professionals can rely on the consistency and quality of the cuts made by this advanced machine.

Overall, the Pneumatic Filament Cutting Machine has proven to be a game-changer in various industries, offering unparalleled versatility, speed, and precision in the cutting of filaments. Its widespread applications across different sectors speak to its effectiveness and efficiency in enhancing production processes and driving innovation in manufacturing. As technology continues to advance, the Pneumatic Filament Cutting Machine is poised to become an indispensable tool for manufacturers seeking to stay ahead of the competition and revolutionize the way they produce goods.

- The Future of Production with Pneumatic Filament Cutting Machines

In today's fast-paced and ever-evolving manufacturing industry, efficiency and precision are key factors in ensuring the success of any production process. As technology continues to advance, so too do the tools and equipment that are used in production facilities around the world. One such innovation that is revolutionizing the way products are manufactured is the pneumatic filament cutting machine.

Pneumatic filament cutting machines are cutting-edge pieces of equipment that utilize pressurized air to cut through various materials with unparalleled accuracy and speed. These machines are able to produce clean, precise cuts on a wide range of materials, including plastic, rubber, and even metal. This level of precision is crucial in industries where even the slightest deviation can result in wasted materials and costly production errors.

One of the key advantages of pneumatic filament cutting machines is their ability to quickly and efficiently cut through even the toughest of materials. Unlike traditional cutting methods, which can be time-consuming and labor-intensive, pneumatic machines are able to make quick work of even the most challenging cutting tasks. This allows manufacturers to increase their production output while reducing the amount of time and labor required to complete each job.

Another major benefit of pneumatic filament cutting machines is their versatility. These machines are capable of cutting through a wide range of materials, making them ideal for use in a variety of industries. From automotive and aerospace to electronics and packaging, pneumatic cutting machines are the go-to choice for manufacturers who require precision and efficiency in their production processes.

Additionally, pneumatic filament cutting machines are also incredibly user-friendly, making them accessible to operators of all skill levels. These machines are equipped with intuitive controls and user-friendly interfaces, allowing operators to quickly and easily set up and operate the machine with minimal training. This ease of use not only reduces the likelihood of operator error but also increases overall productivity in the production facility.

Furthermore, pneumatic filament cutting machines are also highly reliable and durable, ensuring that they can withstand the rigors of constant use in a busy production environment. These machines are built to last, with sturdy construction and high-quality components that are designed to withstand the demands of high-volume production. This reliability means that manufacturers can rely on their pneumatic cutting machines to deliver consistent, high-quality results each and every time.

In conclusion, the pneumatic filament cutting machine is the future of production in the manufacturing industry. With its unparalleled precision, speed, versatility, and ease of use, this cutting-edge technology is changing the way products are manufactured around the world. As manufacturers continue to seek ways to increase efficiency and reduce production costs, pneumatic cutting machines stand out as a game-changer in the quest for innovation and excellence in manufacturing.

Conclusion

Overall, the introduction of the Pneumatic Filament Cutting Machine is set to revolutionize the production industry by streamlining processes, increasing efficiency, and reducing waste. This innovative technology offers a cost-effective solution for manufacturers looking to improve their cutting processes and enhance their overall productivity. With its user-friendly design and precise cutting capabilities, the Pneumatic Filament Cutting Machine is sure to become a game changer in the industry. As more companies adopt this cutting-edge technology, we can expect to see a significant transformation in the way products are manufactured. The future of production is here, and it is powered by the Pneumatic Filament Cutting Machine.

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019