Meixin Comb Brush Machinery

A leader in this industry ,specializing in brush making machine line for more than 14 years

Introduction:

The manufacture of brushes for numerous uses has been transformed by brush machines. These devices have significantly increased output and improved the quality of brushes, from brooms to snow brushes. The development of brush machines has helped to shape the industry into what it is now and has been a monument to human inventiveness and technological improvements. Due to the goal of efficiency, accuracy, and automation, brush machines have seen amazing changes over time. Initially, labor- and time-intensive manual processes, modern automated technologies can now create brushes with unmatched uniformity and quality.

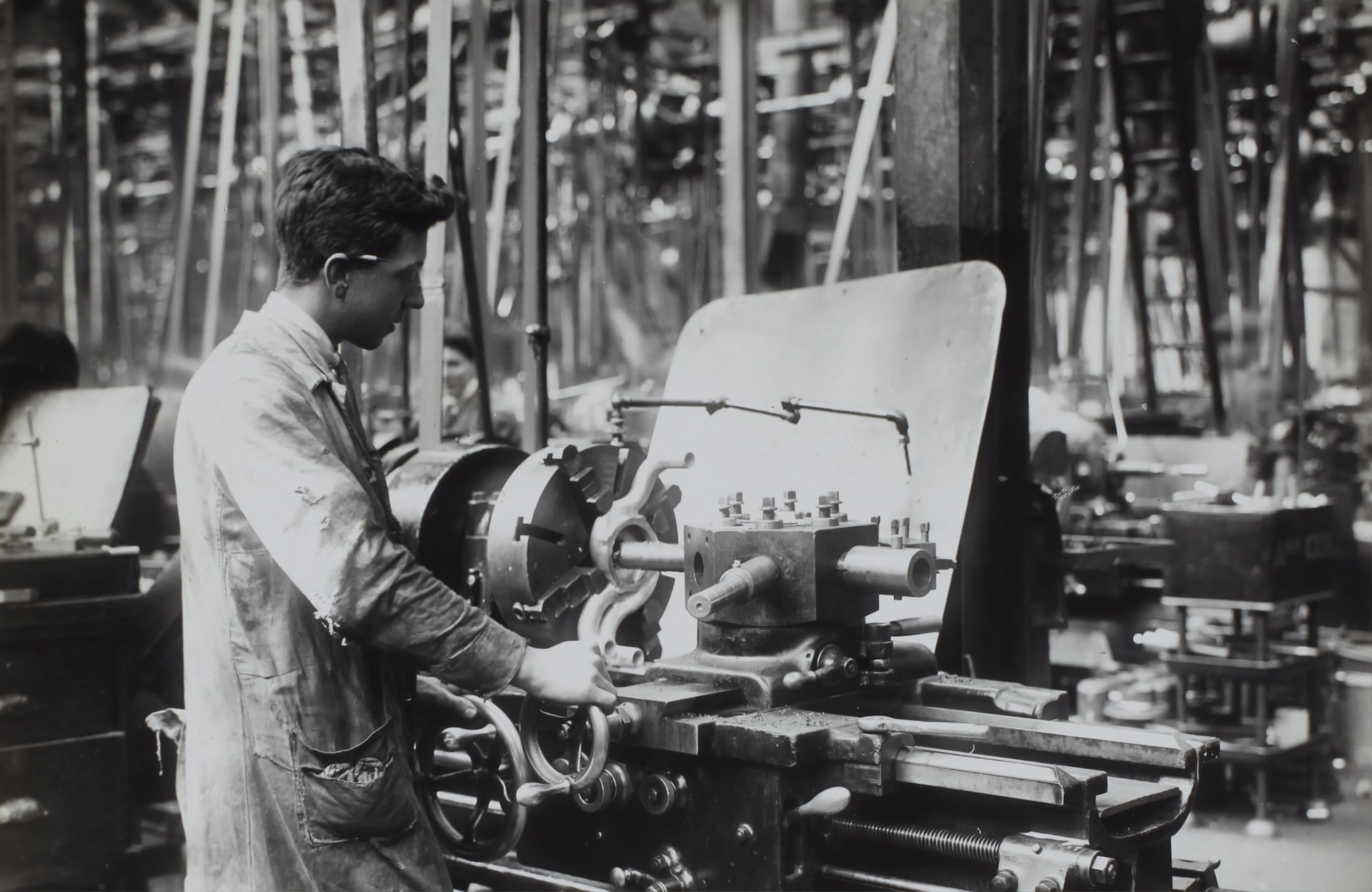

1. Brush Machine History

Brush machines have a rich history that dates back numerous times. Because they were manually operated, early Brush machines demanded a lot of labor and time to produce skirmishes. Still, as technology advanced, automatic Brush machines surfaced, enabling further perfection and effectiveness. These early systems paved the way for the creation of further sophisticated Brush machines that we see moment.

2. Advancements in Brush Machine Technology

Modernistic Brush machines, similar to those manufactured by MX Machinery, have come sophisticated and largely effective. These machines use advanced mechanisms and control systems to automate the Brush product process. One of the crucial advancements in Brush machine technology is the integration of computer numerical control (CNC) systems. CNC technology enables precise control over Brush manufacturing parameters, performing in harmonious and high-quality Brush products.

Likewise, the preface of artificial intelligence (AI) algorithms in Brush machines has further bettered their performance. AI algorithms dissect data from detectors and optimize Brush product parameters in real-time, icing optimal Brush quality and product effectiveness. MX Machinery has been in the van of integrating AI technology into their Brush machines, making them largely advanced and able of meeting the evolving requirements of Brush manufacturers.

3. The Benefits of Using Brush Machines

The application of Brush machines brings multitudinous benefits to manufacturers. Originally, they significantly increase product capacity, enabling the creation of large amounts of skirmishes in a shorter timeframe. Automated Brush machines can operate continuously, minimizing time-out and maximizing affairs. This position of effectiveness allows manufacturers to meet high-demand conditions without compromising on quality. Also, Brush machines ensure harmonious quality, as they exclude mortal crimes and variations that may do during homemade products. The perfection and delicacy of ultramodern Brush machines affect skirmishes with livery bristle lengths, consistency, and patterns. This uniformity is pivotal for skirmishes used in operations similar to sweeping, drawing, and oil, where harmonious performance is needed. Brush machines offer versatility, allowing manufacturers to produce a wide range of skirmishes for different operations. By conforming parameters and tooling, Brush machines can produce skirmishes with varying bristle accouterments, lengths, and shapes. This inflexibility enables manufacturers to feed to different diligence and meet specific client conditions.

4. Conservation Principles for Brush Machines

To ensure the optimal performance and life of Brush machines, proper conservation is pivotal. Regular cleaning, lubrication, and examination of machine factors are essential for smooth and effective operations. In addition to routine conservation, it's pivotal to identify and address any signs of wear and tear, damage, or malfunction instantly. Manufacturers should also keep track of recommended conservation intervals handed by the machine manufacturer, similar to MX Machinery. Clinging to these guidelines helps help unlooked-for breakdowns and ensures that the Brush machine continues to operate at its full eventuality. Maintaining a clean product terrain is essential for Brush machines. Dust and debris can accumulate and affect the machine's performance and delicacy. Regularly drawing the machine and its surroundings helps impurity and prolongs the life of critical factors. By prioritizing conservation and espousing visionary measures, manufacturers can maximize the effectiveness, trust ability, and lifetime of their Brush machines, eventually optimizing their product capabilities and achieving harmonious high-quality Brush products.

5. Machine usage method

Operating Brush machines efficiently requires understanding their functionalities and operation styles. Manufacturers should familiarize themselves with the machine's control panel, programming software, and settings to optimize the production process. Training programs and specialized support from the machine manufacturer, like MX Machinery, can be salutary in educating drivers about the correct operation styles, icing smooth operations, and minimizing time-out.

Conclusion

Brush machines have come a long way, revolutionizing the Brush manufacturing assiduity with their automated capabilities and advanced technologies. With MX Machinery being a world- famed manufacturer, their Brush machines haven't only set new norms in productivity, quality, and versatility but have also propelled the assiduity forward. By following conservation principles, employing proper operation style, and using the slice-edge features of MX Machinery's Brush machines, manufacturers can unleash the full eventuality of these remarkable biases. This leads to enhanced product effectiveness, streamlined operations, and the capability to constantly achieve remarkable results in Brush manufacturing.

Copyright © 2023 Meixin Comb Brush Machinery Co., Ltd. | All Rights Reserved