quality brush tufting machine factory for clothes brushes1

-

v s

1. MEIXIN brush tufting machine is strictly assessed after production. Many factors include part tolerances, size limitations, materials properties, mechanical analysis, and function realization have been analyzed.

2. The product is clean, green and economic sustainable. It uses perennial sun resources freely to offer power supply for itself.

3. The product features safety during operation. The electrical system and its relevant accessories all meet the requirements of IEC general standards.

4. Our customer service team has been always dedicated to solving problems about brush tufting machine.

special features:

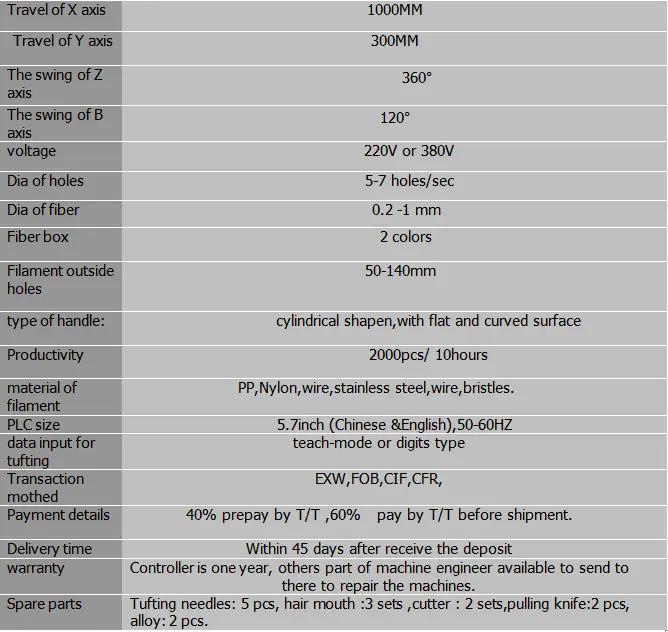

1. With one tufting heads,independent 4 axis motion ,it used for the any shape pf brooms. Like flat brooms and other shape of brooms. It suitable for any wooden or plastic brush handles tufting.

2. The filament outside hole can be 50-140mm.

2.FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

3.This machine with the new design of tufting.easy operate.

B/ brand of motor in the machine.

1.Delta inverter, Panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller.

C/Controller features:

1. its provided with manual data input as well as teach in data input method. With the 5.7 touch display, it can work with the Chinese or English.

2. auto or step operation.

3. speed of tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features

1. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY establishes a tenacious foothold in the manufacturing industry. We design, manufacture, and deliver brush tufting machine to accommodate customer needs perfectly at competitive prices.

2. Covering a large scale, the factory owns 50% of highly automatic production lines. With space combining with technologies, we can flexibly arrange the production lines to coordinate the production demands.

3. The goal of JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY is to build a brand name through excellent quality and mature after-sales service. Ask online! People are at the heart of everything we do. We care about our employees, communities and the environment around us and we want to make sure we have a positive impact on all three. Ask online! We are full of confidence in our quality Brush Making Machine . Ask online!

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019