US $1-4 / Meters | 200 Meter/Meters (Min. Order)

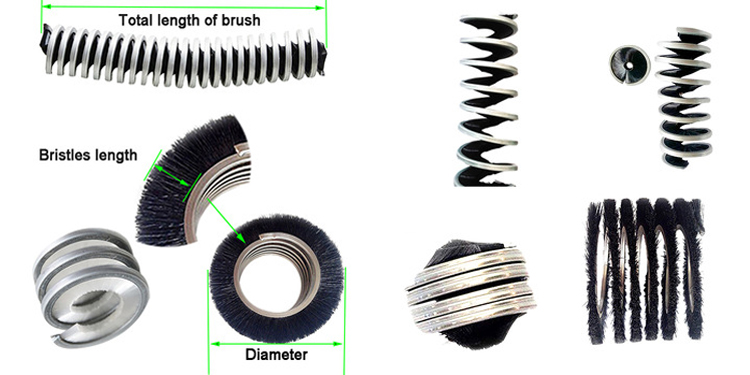

Material: Nylon wire, other

Application: Industry cleaing, polishing

Color: Black, Custom

Size: Customized

Certification: ISO, SGS, CE

Sample: Available

MOQ: 200 Meters

Supply Ability:10000 Meter/Meters per Month

Filament material: | Steel wire, nylon, PP, stainless steel, etc |

Base material: | Stainless steel, aluminium, etc. |

Usage: | Steel, furniture, wood, etc. |

Copyright © 2023 Meixin Comb Brush Machinery Co., Ltd. | All Rights Reserved