Company Advantages1. The design for brush tufting machine is so important that we will never neglect it. Meixin's products cover various sizes of machines and are popular among customers with computer screen display

2. The product, with great commercial value, meets the demanding requirements of global customers. Meixin products enjoy one-year warranty

3. Product quality meets industry standards and has passed international certification. Meixin supplies high-quality

brush machine4. The performance and quality of the product is stable and reliable. Meixin innovative ability enables to constantly develop new products

special features:

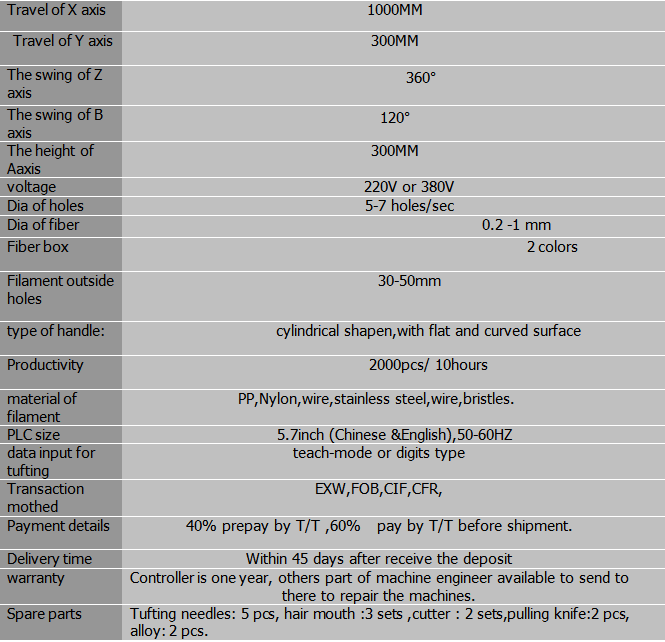

1. FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

2. Independent 4 aix motion ,suitable for plastic hokey brush handles tufting.

3.this machine with the new design of tufting.easy operate.

4.high speed, working around 2300 pcs/10 hours.

A/ brand of motor in the machine

1.Delta inverter, Panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller.

B/Controller features:

1. its provided with manual data input as well as teach in data input method.

2. auto or step operation.

3. speed of tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features1. With the expanding of brush tufting machine, MX machinery has caught more and more attention of the customers.

2. We have a motivated, experienced customer service team that works directly with our customer's engineers to provide high-level assistance. From the pre-development, the design phase to production and after-sales stages, they are able to offer all kinds of supports to clients.

3. Our company bears responsibilities. Sustainable and responsible action is an aspiration and commitment for everyone in our company – something that is firmly anchored in our values and corporate culture.