Company Advantages1. This new type brush tufting machine called brush making equipment is gradually widely used with its outstanding design. The products must be 100% tested to ensure their functionality, reliability, security and durability before shipment

2. Thanks to its durability, the product can be used for a long time. This is not only beneficial for business owners and allowing the production projects to be finished in a short time, reducing the waste of time. Meixin products have been approved several International Certification

3. It has the proper size in consideration of the force. Each element of this product is designed with the most suitable size by considering the force acting on it and the permissible stresses for the material used. Meixin supplies high-quality

brush machine4. The product features strong resistance to corrosion. Non-corrosive materials have been used in its structure to enhance its capacity to withstand rust or acidity liquid. Meixin keeps strict quality control of the products

5. The product is energy saving. The design adopts the latest energy conservation technologies which significantly reduces energy consumption. Meixin products have been exported to India, South American and so on

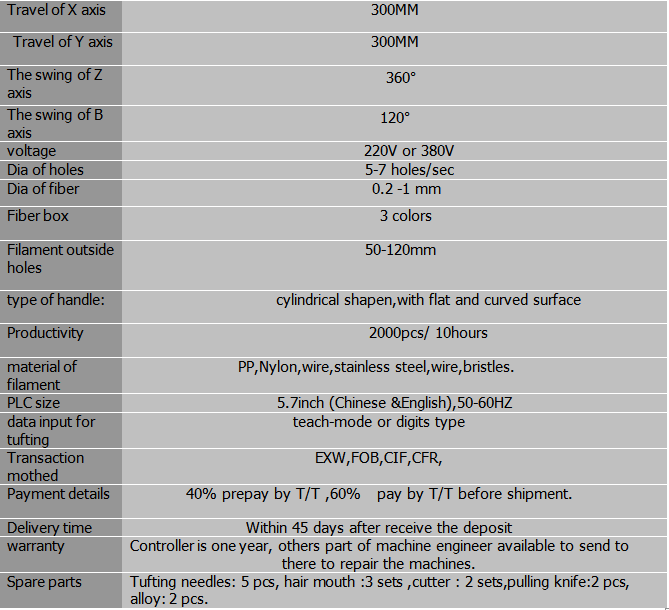

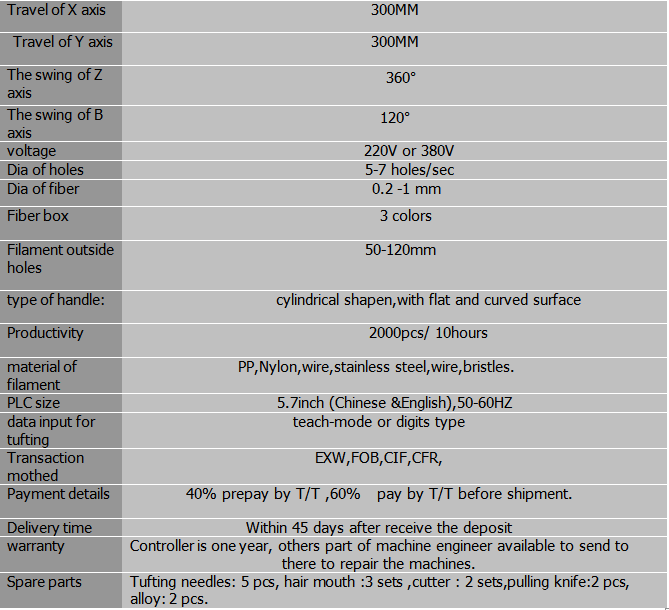

special features:

1. With one tufting heads,independent 4 axis motion ,it used for the any shape pf brooms. Like flat brooms and other shape of brooms. It suitable for any wooden or plastic brush handles tufting.

2.FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

3.This machine with the new design of tufting.easy operate.3 colors.

4. With the 5.7 touch display, it can work with the Chinese or English.

A/ brand of motor in the machine

1.Delta inverter, Panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller

B/Controller features:

1. its provided with manual data input as well as teach in data input method.

2. auto or step operation.

3. speed of tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features1. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY has been operating for many years and has been considered a reliable manufacturing factory for brush making equipment.

2. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY owns a group of experienced processing engineers and designers.

3. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY believes it have the ability to be the leader in manufacturing brush tufting machine. Welcome to visit our factory!