Company Advantages1. MX machinery steel

brush machine is designed and manufactured with the aid of the best quality raw materials and advanced technology in line with set industry norms. Professional pre and after-sales service are also provided by Meixin

2. The product is widely used and has a high market value. Ease of installation is one of the most characteristics of Meixin products

3. The product is efficient in removing dirt and contaminant. Due to its extremely small polyporous filter elements, any harmful substances, small molecule or macromolecular, will be removed effectively. "Meixin brush machine is of best sophisticated design

4. This product has strong electromagnetic compatibility. It is not likely to be affected by external devices or cause intolerable electromagnetic interference to its surroundings. What's more, Meixin products are widely used in all kinds of brushes making

special features:

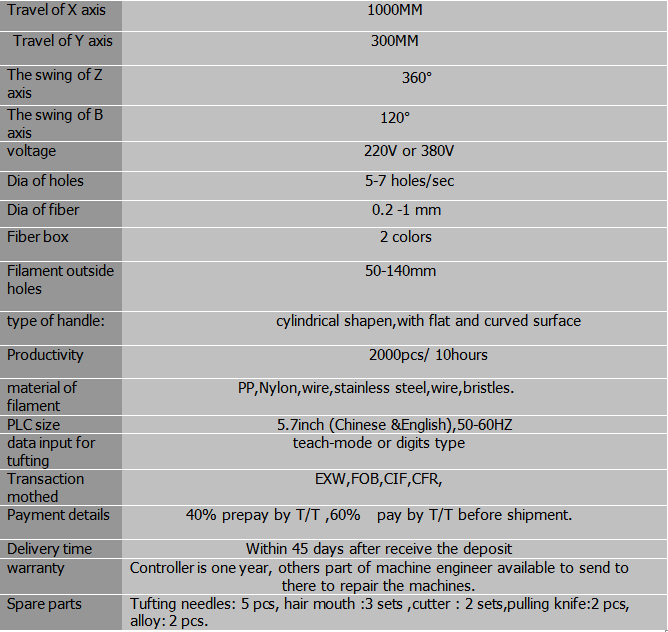

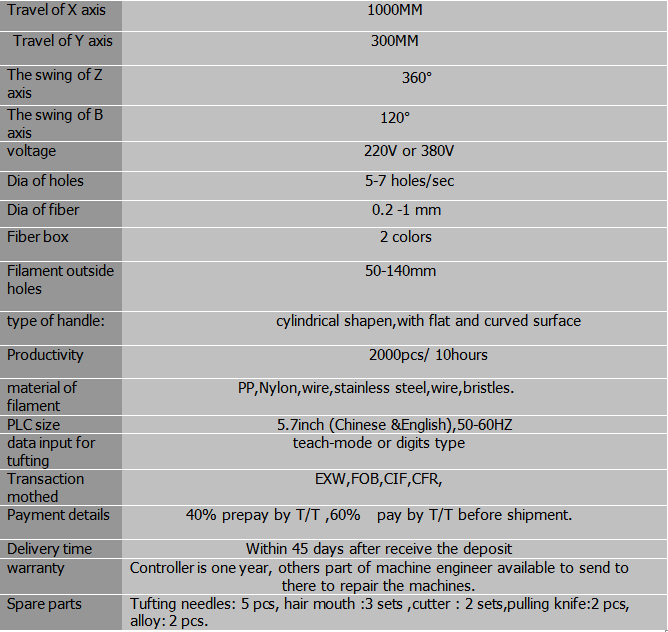

1. With one tufting heads,independent 4 axis motion ,it used for the any shape pf brooms. Like flat brooms and other shape of brooms. It suitable for any wooden or plastic brush handles tufting.

2. The filament outside hole can be 50-140mm.

2.FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

3.This machine with the new design of tufting.easy operate.

B/ brand of motor in the machine.

1.Delta inverter, Panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller.

C/Controller features:

1. its provided with manual data input as well as teach in data input method. With the 5.7 touch display, it can work with the Chinese or English.

2. auto or step operation.

3. speed of tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features1. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY has always made every effort to develop premium marketed Brush Making Machine and satisfy every customer's requirement. The technical power is JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY's base of development.

2. As a technically competitive enterprise, JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY owns several brush tufting machine production lines.

3. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY has experts with practical experiences who devote themselves to Brush Making Machine field. We put special emphasis on increasing energy efficiency. We want to lead the way for other companies, for example by investing in solar energy.