MEIXIN high productivity Brush Making Machine inquire now for broom

1. The design of MEIXIN brush making machine for sale is aspired by the latest market trends.

2. It has good stiffness and rigidity. Under the effect of applied forces for which it is designed, there is no deformation beyond the specified limits.

3. This product has good strength. Various types of load and stresses caused by the load are analyzed for choosing the best structure and materials for its strength.

4. The product leads to a lower amount of money spent on purifying clean water. This can add up to considerable cost savings in the long run.

5. The product has been well treated so that it will stand the test of time and look better and more luster with age.

special features:

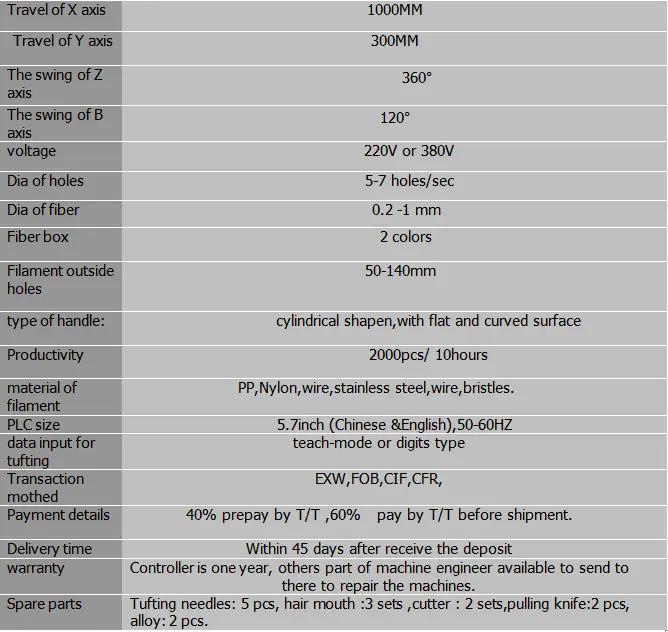

1. With one tufting heads,independent 4 axis motion ,it used for the any shape pf brooms. Like flat brooms and other shape of brooms. It suitable for any wooden or plastic brush handles tufting.

2. The filament outside hole can be 50-140mm.

2.FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

3.This machine with the new design of tufting.easy operate.

B/ brand of motor in the machine.

1.Delta inverter, Panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller.

C/Controller features:

1. its provided with manual data input as well as teach in data input method. With the 5.7 touch display, it can work with the Chinese or English.

2. auto or step operation.

3. speed of tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features

1. MEIXIN gets the hang of fashion trend and does our utmost to create a international pattern.

2. Over the years, we have offered many OEM productions services for some world-renowned brands. They are quite satisfied with our product quality and recommend some of their partners to us.

3. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY will provide sincere, enthusiastic and considerate service to our customers. Call! Indeed, brush making machine for sale is a principle tenet of JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY. Call! JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY highly values the importance of enterprise culture. Call! Such business principles and strategic guidelines as steel wire brush machine have been formed through the course of JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY's development. Call!

Complete Process

Mixing → Feeding → Extruding → Mold → Extension → Oven or Water tank → Second Extension → Winder→ Final product:

Essential parts of the machine:

1, Automatic Feeder + Mixer

2, Hopper+ barrel (screw)

3, Spinneret

4, Cooling water tank

5, Stretch roller A (7 rollers)

6, Hot water tank

7, Stretch roller B (5 rollers)

8, Winder (olivary bobbins )

Composition

The machine, using material of polypropylene and high density polyethylene, through

heating, extruding and drawing, makes tape or fiber that is then winded for the

weaving of the circular loom.

Having been improved so many times, the machine can use 100% recycled or 100%

new PP and PE granules or powder to produce yarn. The screw and cylinder are made

of nitrided 38CrMoAlA alloy steel, the hardness of which can reach over HV 950.

Helical gear reducer made of 20CrMnTi alloy is applied to the extruders as well. The

chain wheel adopts 45# medium carbon steel after being treated by high-frequency

quench. The driving rollers are electroplated with hard Cr and the self-control tension

winding roller is adopted by the traction unit

Purpose

plastic extruder machine

This machine is suitable for productio of monofilament by HDPE or PP as raw material

for making rope and fish net.

It can produce fibre ,line,tube,rope,film,board,net,plates, granule ect.

Product Type: Plastic Rope

Extruder can produce many kinds of fibre,such like HDPE and PP monofilament

fiber,danline fibre,flat film fibre,split film fibre,PP multifilament fibre and PET

multifilament fibre and etc.The fibres can be used for the manufacturing of

industry,fishing industry ,and civilan use,such like rope ,fishing net,construction safety

net ,pp bag and etc.

Advantages

1:Extruder machine can make any item and any color plastic yarn

2:High quality with competitive price

3:High extrusion capacity

4:Stable operation

5:High torque and output

6:With adjustable speed.

7:Nice apperance, automatic control,.

8:It's power consumption is very low

9:Low noise level

10:High output,high performance, and low cost

11:Automatic temperature control

12:Single or double screw can be choice

13:Easy to operation,steady operation

14:Can use recyle material and new material

Product Picture

Company Profile

Shandong Rope Net Machinery Co.,Ltd,we are manufacturer of kinds of extruders ,(PP,PE,PET,Monofilament fiber, film fiber, flat fiber ),ring twister,twisted and braided rope making machine,rope packing machines ,winding spool machine winding ,ball machine ,shrink machines and strapping machines.We have gain the ISO9001:14001 certification

We have 5 factories to produce rope and 1 factory to produce machinery,our rope and machinery products are mainly exported to the whole world,we have professional engineer to your configuration for your equipment, our professional and technical personnel to help you produce high quality products

Our Team and Certificate

FAQ

The machines will be made as your requirements. We are appreciated if you can provide the information as follows:

1: How much is the specifications of the fiber?

2. What is the capacity you want to make ?

3: What is your country's voltage ?

Our Service

1.Installation Services

Installation Services are available with all new machine purchases. We will provide the technical know-how for your operation smooth transition and support for installing, debugging, operation of the machine, it will indicate you how to use this machine well.

2.Clients Traning Services

We can train your staff to use your equipment systems properly.It means that we offer Customers Training, teaching how to use the systems most efficiently and safely as well as how to maintain optimal operational productivity

3.After Sales Service

We offer the Preventative Maintenance and After Sales Service. For we strongly feels about the importance of supporting our customers and the product solutions we provide.Consequently we offer comprehensive maintenance options to prevent equipment issues before they become problems. Also we offer one year guarantee period.

In one words,your satisfication is our persuit forever!

Why Choose Us

1. Best material selection

"Quality is life" .

All our goods are made of the best raw materials from the best suppliers.

2. Professional producing

"Profession gets trust"

We produce all goods by ourselves. We have skilled workers ,strict QC,professional engineers and sales.

3. Prompt Shipment

"Time is gold"

We have good cooperation with our Shipping Agent.They are professional,ensure the good service and price.

4. Good after sales service

"Focus on long-term cooperation "

After sales service is necessary for more understanding for your needs. We do keep a close concern for our cooperation

We are one of the very few suppliers that can produce a complete set of rope making machines in China.

1.PP PE Plastic Monofilament /Danline Extruder (65mm,70mm,75mm,90mm,100mm,120mm)

2.Plastic film/tape extruder Machine,PP FDY spinning machine

3.Ring twister.

4.Twisted rope making machine.

5.Braided rope making machine.

6.Ball winding machine.

7.Spool winding machine

Welcome your enquiry and suggestion!

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019