MEIXIN double head plastic broom making machine wholesale for broom

1. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY strictly adopts superior raw material for plastic broom making machine. Meixin innovative ability enables to constantly develop new products

2. The product can have a positive impact on a company’s efficiency, enabling employees to work faster and increase productivity. Wearing parts and spare parts are of standardized design

3. plastic broom making machine comes with such advantages as brush making supplies in comparison with other similar products. Meixin uses stable motor and metal box to reduce noise

4. By using advanced production technology, performance such as brush making supplies has been realized on plastic broom making machine. Ease of installation is one of the most characteristics of Meixin products

5. plastic broom making machine are rich in brush making supplies . Meixin can make the machine according to customers' requirements

special features:

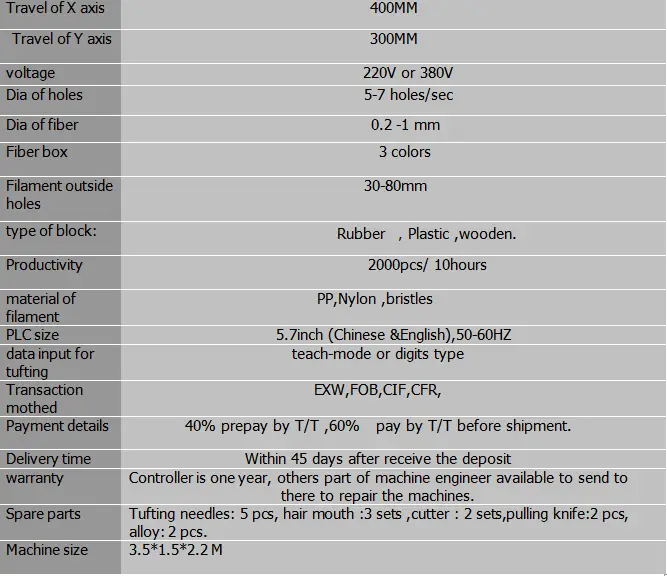

1. This machine with one tufting heads, independent 2 axis motion, only for tufting. Please be sure that the plastic head or block have been drilled.

2. The speed is 5-7 holes/sec .

3. FMX fixture allows fast change over for a new brush tufted production.

3.This machine is used to product the snow brushes.

4. About the touch display, it has teo lauguafe syatem, Chinese and English .

5. you can tuft in the machine with the PP,PET,others

brand of motor in the machine

1.Delta inverter, Panasonic servo motor .

2.Taiwan TBI ball screw guide way and Taiwan HIWIN .

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller

B/Controller features:

1. its provided with manual data input as well as teach in data input method.

2. auto or step operation.

3. speed of tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features

1. Since the foundation, JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY has built a reputation in the field of developing and manufacturing of brush making supplies . Precision instruments for plastic broom making machine are equipped by JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY.

2. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY has advanced computer-controlled machines and blameless checking equipment for Brush Making Machine production.

3. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY adopts high-end technology and implement strict measures to control quality of plastic broom making machine. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY solely concentrates on exporting therefore, we offer very competitive prices. Ask!

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019