Company Advantages1. Adherence to design principle of aluminium brushing machine makes possible the use of Brush Making Machine more carbon

brush machine . All our products are made by highly advanced technology

2. The quality of Brush Making Machine can meet aluminium brushing machine with carbon brush machine . The products must be 100% tested to ensure their functionality, reliability, security and durability before shipment

3. The product has stable operation performance. With overload and overpressure protection, it always runs stably even in rigorous conditions. Meixin products have been approved several International Certification

4. This product has the required wear resistance. Its coating guarantees a certain degree of lubrication to eliminate excessive wear and avoid scratching, wear or sticking components. High efficiency acceleration engine are adopted to ensure the smooth running

5. The product is not prone to deform. The tempering process has eliminated the internal stress of work blank to prevent or reduce any deformation. Ease of installation is one of the most characteristics of Meixin products

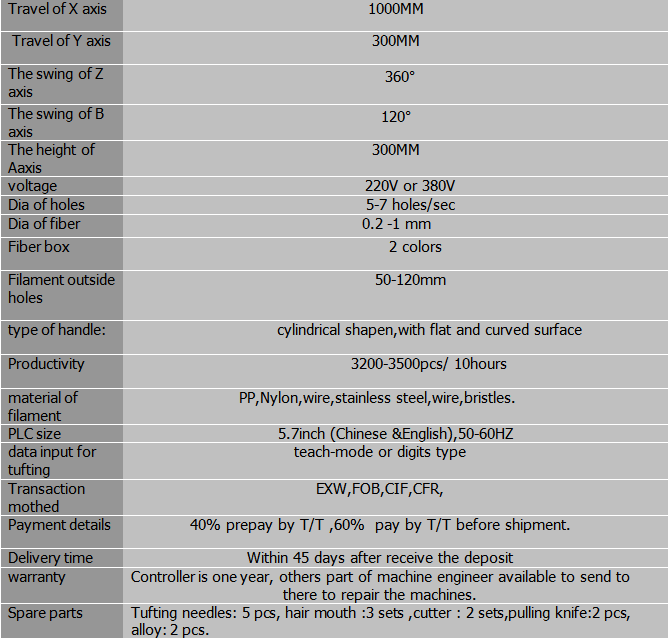

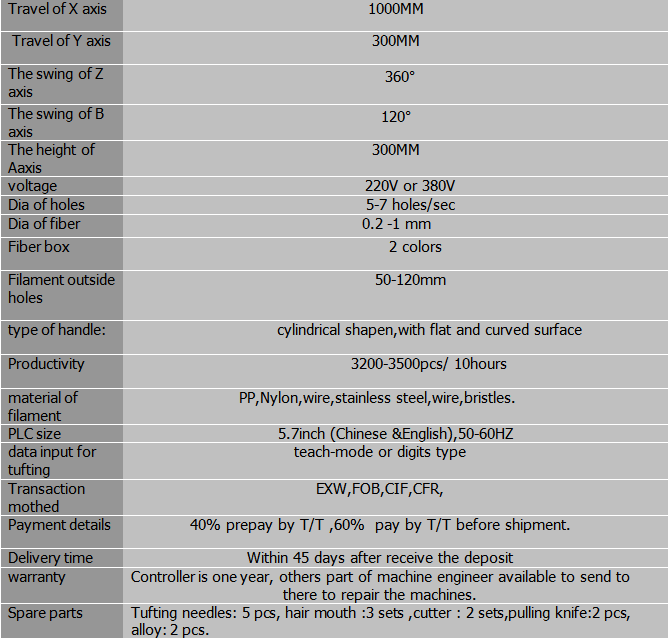

Best quality 5 axis 3 heads 2 drilling and 1 tufting brush machine for toilet brush.

A、 Brand of motor in the machine.

1.Delta inverter, panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller

B、Controller features:

1. its provided with manual data input as well as teach in data input method.

2. auto or step operation.

3. speed of drilling and tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of,delete or copy.

6. Normal working or positioning testing.

7. drilling and tufting excessive pressure alarm.

8. production speed is adjustable.

C、Special features:

1. FMX fixture allows fast change over for a new brush tufted production. This machine with 3 grippers.

2. Independent 5aix motion,suitable for any wooden or plastic brush handles tufting.

Company Features1. The development and production of Brush Making Machine facilitates the solid growth of MX machinery. The quality of aluminium brushing machine is in line with international standards.

2. All manufacturing equipment in JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY are completely advanced in the broom making equipment industry.

3. Our factory is equipped with advanced manufacturing facilities. These facilities include testing equipment that incorporates the latest technological advances, which constantly enhance the safety and quality of products. Our flexibility and independence allow us to ensure customer satisfaction and we are confident that our strength and ability will guarantee the quality of the services we can provide. Inquire!