special features:

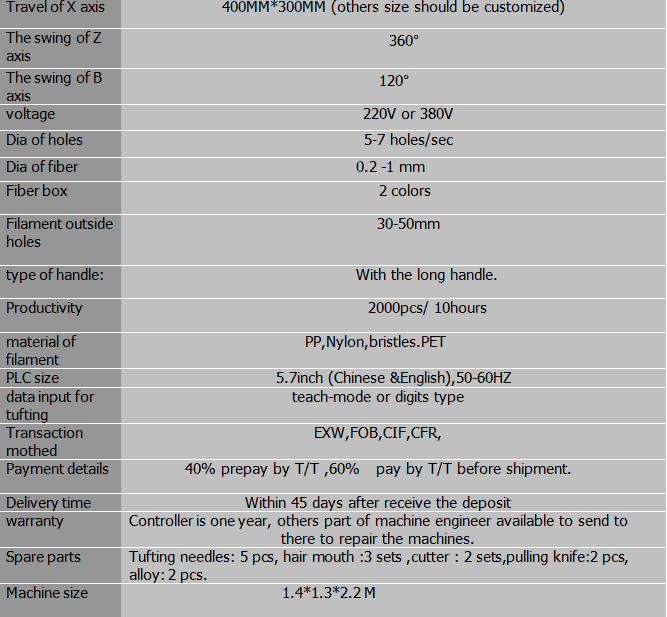

1. With one tufting heads,independent 4 axis motion ,it used for small round toilet brush, others. It suitable for any plastic brush handles tufting.

2. The filament outside hole can be 30-50mm.

3.FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

4.This machine with the new design of tufting.easy operate.

5. Please note that The productivity is 2400-2600 pcs/10 hours.

Copyright © 2023 Meixin Comb Brush Machinery Co., Ltd. | All Rights Reserved