Company Advantages1. The modern manufacture technology guarantees the production of MX machinery steel wire

brush machine . Meixin products have been approved several International Certification

2. Now, JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY is proud to say that we are the expert on customized Brush Making Machine products. Meixin products enjoy one-year warranty

3. Strict quality standards are established in the inspection process to ensure the high quality of products. The quality of the products also has been strictly controlled by Meixin

4. The product is of good quality and excellent performance. Professional pre and after-sales service are also provided by Meixin

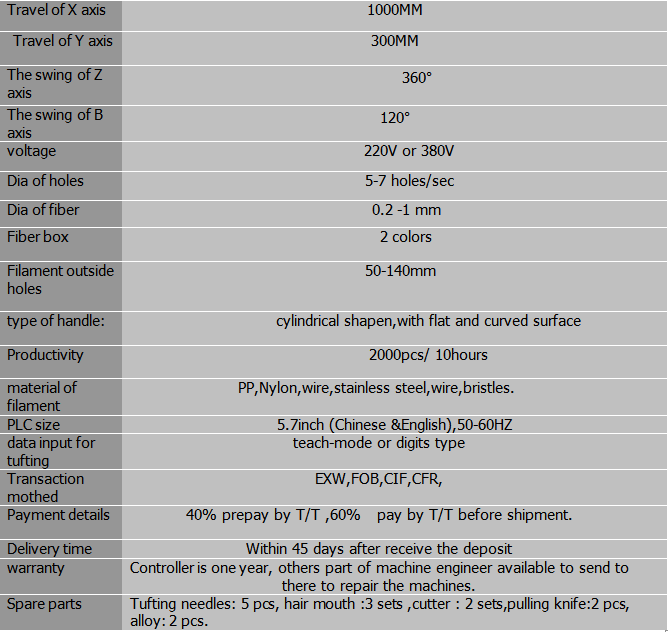

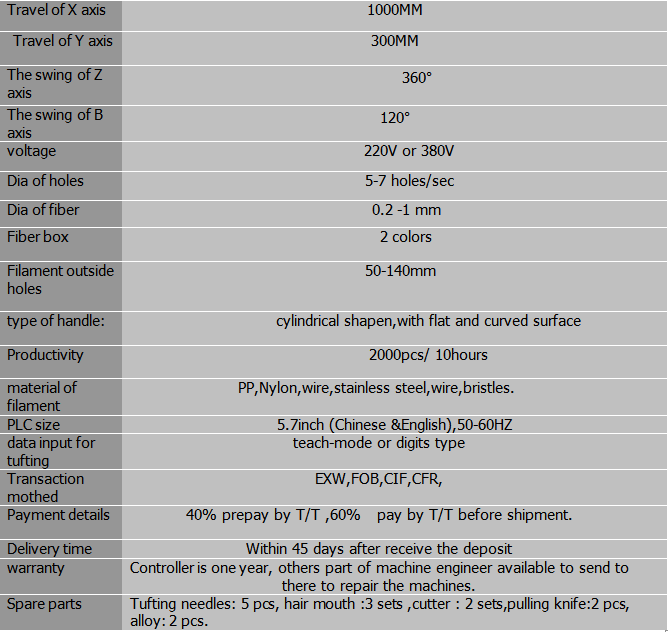

C/special features:

1. With one tufting heads,independent 4 axis motion ,it used for the small roller brush. Like brush for the jade brush .It suitable for any wooden or plastic brush handles tufting.

2.FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

3.This machine with the new design of tufting.easy operate.

4. With the 5.7 touch display, it can work with the Chinese or English.

A/ brand of motor in the machine

1.Delta inverter, Panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller.

B/Controller features:

1. its provided with manual data input as well as teach in data input method.

2. auto or step operation.

3. speed of tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features1. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY is an approved manufacturer of steel wire brush machine both in the domestic and international market. We have earned a good reputation over the years. Being professional in producing Brush Making Machine , MX machinery owns highly developed technology.

2. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY is well-known for its cutting edged production technology.

3. Putting large amount of investment into the technical force facilitates the popularity and fame of both brush tufting machine and MX machinery. Our company insists that the market monitor our results. Inquire now!