4 Axis 1 Head Broom Tufting Machine

1. MEIXIN steel wire brush machine goes through a series of production processes. They involve CAD/CAM design, prototyping, milling, turning, fabrication, welding, spraying, and commissioning.

2. The product has a smooth and flat surface. The singeing technique which quickly passes yarn or fabric through a flame or rubs it over a hot metal surface to remove the surface hairs.

3. The product is prominent in energy saving. The energy-keeping technology adopted increases power and balances the voltage, which helps reduce power consumption.

4. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY grasps the essential laws of objective things and the nature of human nature, and develop harmoniously.

5. 'Mutual care and mutual achievement' are the principles that JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY has been adhering to the company's internal interaction with customers.

special features:

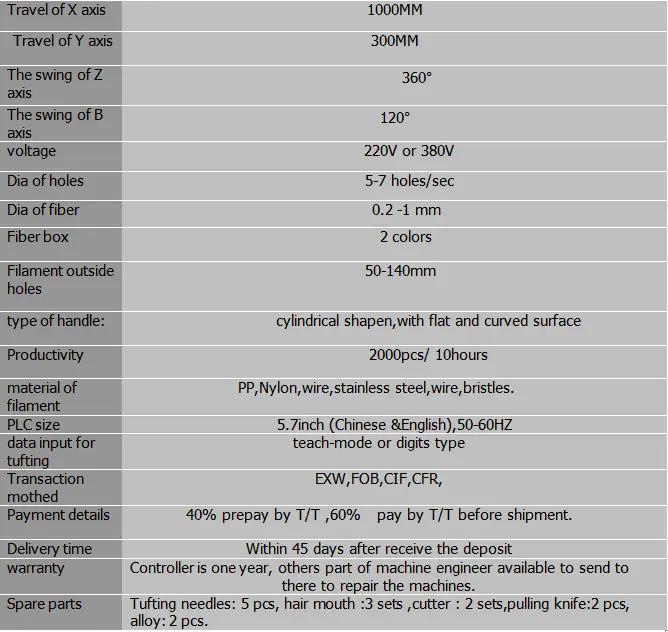

1. With one tufting heads,independent 4 axis motion ,it used for the any shape pf brooms. Like flat brooms and other shape of brooms. It suitable for any wooden or plastic brush handles tufting.

2. The filament outside hole can be 50-140mm.

2.FMX fixture allows fast change over for a new brush tufted production. This machine with 2 grippers.

3.This machine with the new design of tufting.easy operate.

B/ brand of motor in the machine.

1.Delta inverter, Panasonic servo motor.

2.Taiwan TBI ball screw guide way and Taiwan HIWIN.

3.Schneider low voltage electrical appliances.

4.JAPAN CLOSE WITH BEARING.

5.Germany SENLIMA brake motor.

6.SHENZHEN ATECH controller.

C/Controller features:

1. its provided with manual data input as well as teach in data input method. With the 5.7 touch display, it can work with the Chinese or English.

2. auto or step operation.

3. speed of tufting is controlled by inverter for various speed adjustment.

4. test mode to test machine if functions properly.

5. editing features of ,delete or copy.

6. Normal working or positioning testing.

7. tufting excessive pressure alarm.

8. production speed is adjustable.

Company Features

1. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY is a Brush Making Machine supplier with extensive industry experience.

2. JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY constantly implements the research and development to improve its competitiveness.

3. The practice of steel wire brush machine will be the focus of JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY’s work in the future. Get info! JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY will respond to market changes and create service differences. Get info! JIANGMEN MEIXIN COMB BRUSH MAKING MACHINE FACTORY is striving for world-class brush tufting machine supplier. Get info!

3 monthes only used double hockey,washing brush making machine----Urgent for sell

Bharat Sharma

00919837030603(cell) whatsapp

QUICK LINKS

PRODUCTS

CONTACT US

Contact Person: Leo

Email: Mxdx@Mxbrushmachinery.Com

Tel: +86 13232438671

Skype/Facebook: +86 13232438671

Fax: 0750-6575221

Address: Heqiaolingwu Road, Sanyi Industrial Estate, Siqian Town, Xinhui District, Jiangmen City, Guangdong Province, China (Pc:529159)Pe 2019